Graphene-containing insulated radiating composition and preparation and application thereof

A technology of graphene and composition, which is applied in the field of insulating and heat-dissipating compositions, can solve problems such as difficulty in having both insulation and thermal conductivity, achieve good thermal conductivity, widen application space, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

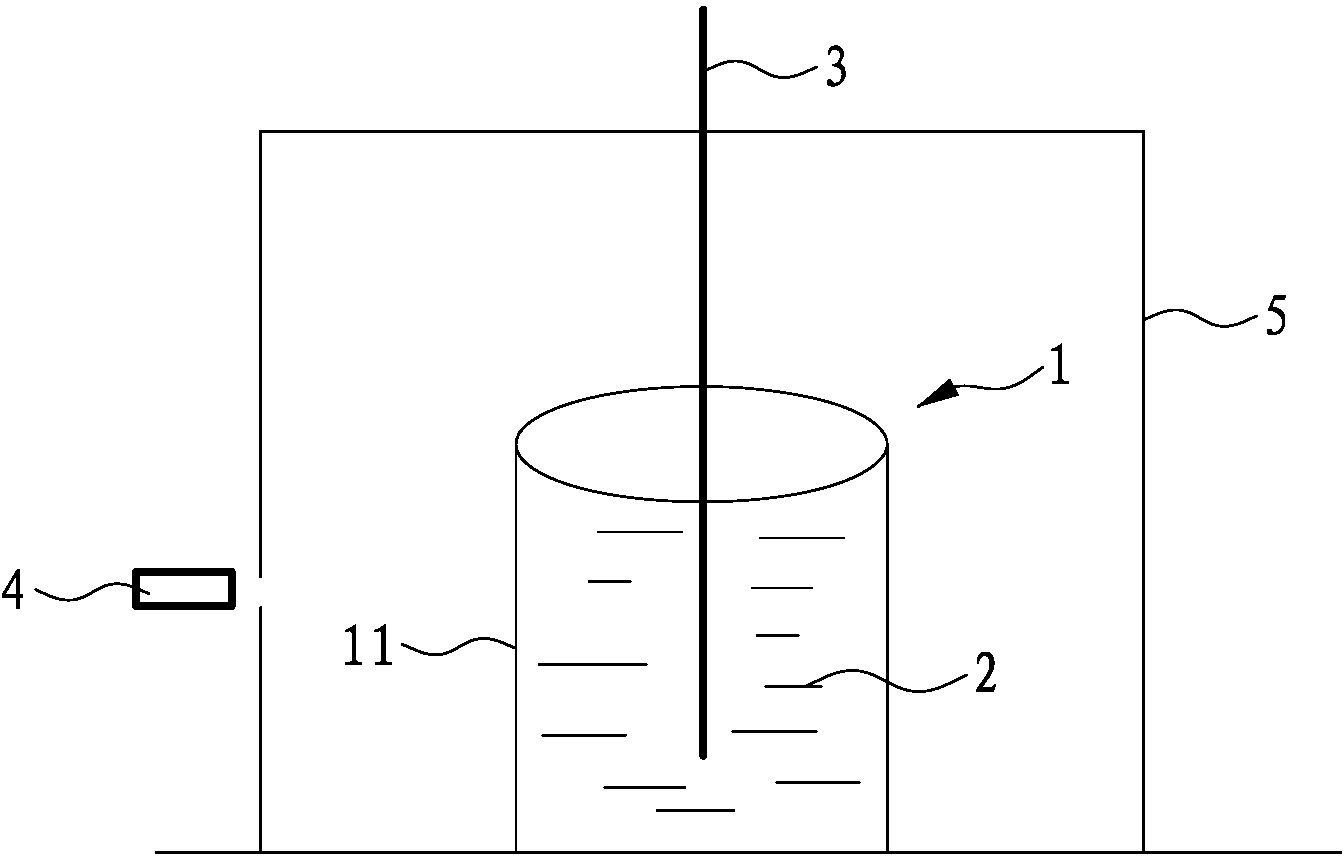

Image

Examples

preparation example Construction

[0031] The preparation method of the insulating and heat-dissipating composition containing graphene of the present invention specifically comprises the following steps:

[0032] (1) Using tetraethyl orthosilicate as raw material, add graphene and add water and ammonia water drop by drop in the process of ultrasonic and ultra-high-speed stirring. The dripping rate of the water and ammonia water is 0.5-1ml / min, so that the Ethyl ester is hydrolyzed on the surface of graphene, and then reacted at 50-70°C for 1-3 hours. The generated silicic acid is coated on the surface of graphene, and then dried at 120-150°C for 2-6 hours. hours, a silicon dioxide film is finally formed on the graphene surface;

[0033](2) After dissolving and diluting the surface treatment agent with a solvent, add it to the mixture of the insulating conductive filler and the above-mentioned modified graphene, and stir evenly. After the above mixture is fully mixed with functional additives, it is poured int...

Embodiment 1

[0038] (1) Take 15g of tetraethyl orthosilicate as raw material, add 15g of graphene microflakes (KNG-180-D031), add water and ammonia water drop by drop in the process of ultrasonic and ultra-high-speed stirring, and make ethyl silicate in graphite Hydrolyze the surface of alkene, then keep it warm at 60°C for 2 hours, the generated silicic acid is coated on the surface of graphene, and then dry at 130°C for 5 hours, and finally form a silicon dioxide film on the surface of graphene;

[0039] (2) Dilute 2g of silane coupling agent (KH792) with water and add to the mixture of 25g of needle-shaped zinc oxide, 30g of spherical alumina and the above-mentioned modified graphene, and stir evenly. After the above mixture is thoroughly mixed with 10g of phenolic resin and 10g of polyethylene glycol, it is poured into a ball mill for ball milling dispersion treatment to obtain a wet concentrated composition.

Embodiment 2

[0041] (1) Take 30g of tetraethyl orthosilicate as raw material, add 30g of graphene microflakes (KNG-180-D031) and add water and ammonia water drop by drop in the process of ultrasonic and ultra-high-speed stirring, so that ethyl silicate Hydrolyze the surface of alkene, then keep it warm at 60°C for 2 hours, the generated silicic acid is coated on the surface of graphene, and then dry at 130°C for 5 hours, and finally form a silicon dioxide film on the surface of graphene;

[0042] (2) Dilute 2g of silane coupling agent (KH792) with water and add to the mixture of 25g of needle-shaped zinc oxide, 30g of spherical alumina and the above-mentioned modified graphene, and stir evenly. After the above mixture is thoroughly mixed with 10g of phenolic resin and 10g of polyethylene glycol, it is poured into a ball mill for ball milling dispersion treatment to obtain a wet concentrated composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com