A kind of gan-based led microdisplay device and manufacturing method thereof

A technology of a microdisplay device and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electric solid-state devices, etc., can solve the problems of easy breakage of connecting lines, poor stability, thin thickness, etc., and achieves improved luminous brightness and thermal stability. Good performance and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

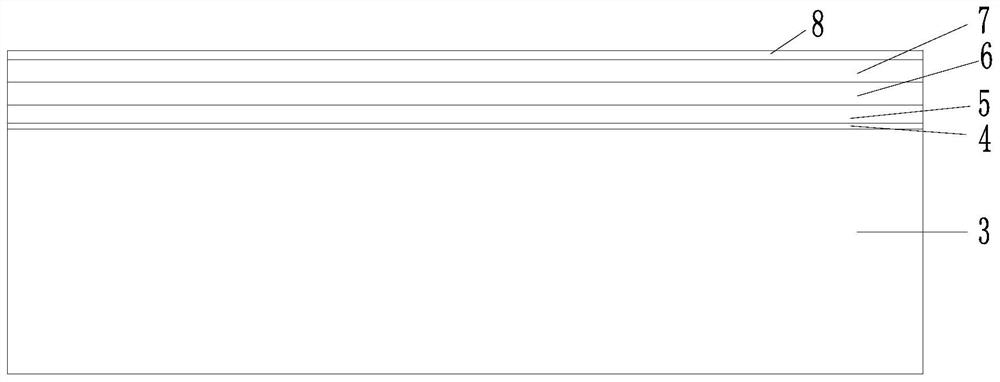

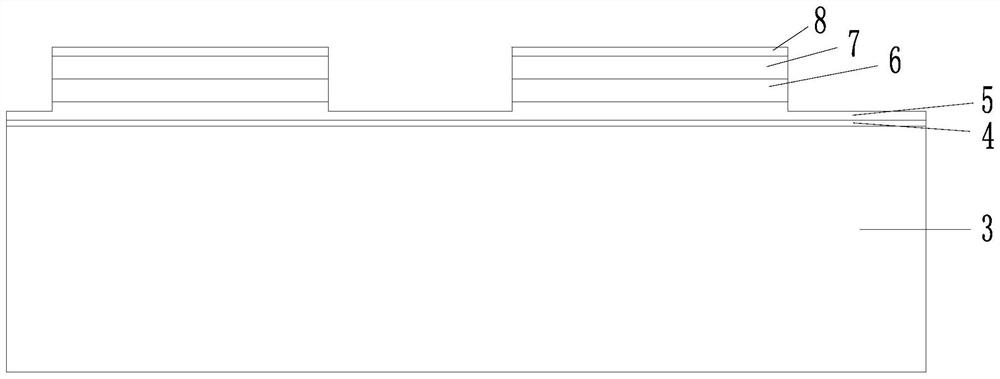

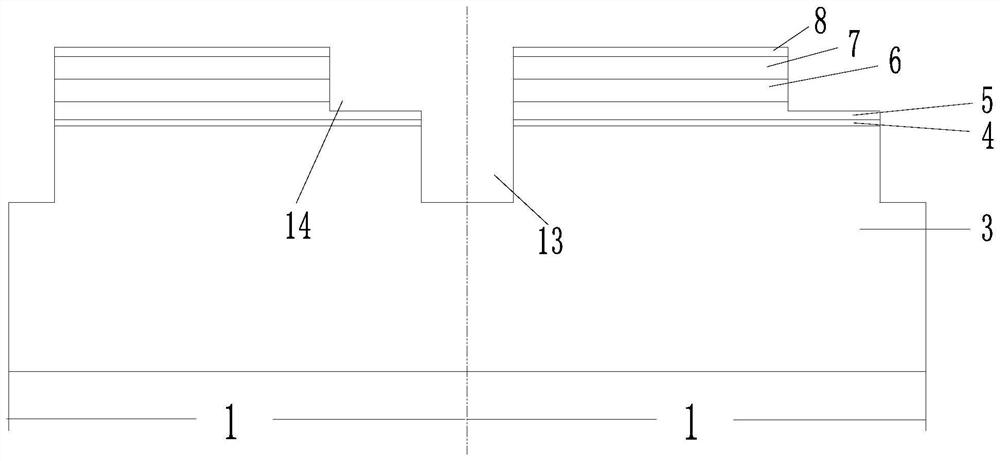

[0038] Embodiment 1: as Figure 7 and Figure 8 As shown, a front-mounted GaN-based LED micro-display device includes a sapphire substrate 3, and several LED micro-display units 1 distributed in an array are arranged on the front of the sapphire substrate 3;

[0039] The LED micro-display unit 1 includes a buffer layer 4, an N-GaN layer 5, a multiple quantum well 6, a P-GaN layer 7 and a transparent conductive layer 8 on a sapphire substrate 3, and the transparent conductive layer 8 includes ITO. The N-GaN layer 5 is provided with an N electrode 11, and the N electrode 11 and the insulating SU8 glue 9 are provided with SiO 2 Insulation layer 10, SiO 2 a P electrode 12 on the insulating layer 10, and the P electrode 12 passes through the SiO 2 The insulating layer 10 is in contact with the transparent conductive layer 8;

[0040] A Bragg reflector DBR 2 is arranged on the back of the sapphire substrate 1; the Bragg reflector DBR2 includes multiple sets of alternately distri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com