Novel LED die bonding method

A new type of crystal-bonding technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as insufficient light output from LEDs, achieve the effects of reducing coverage area, enhancing directivity, and increasing output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

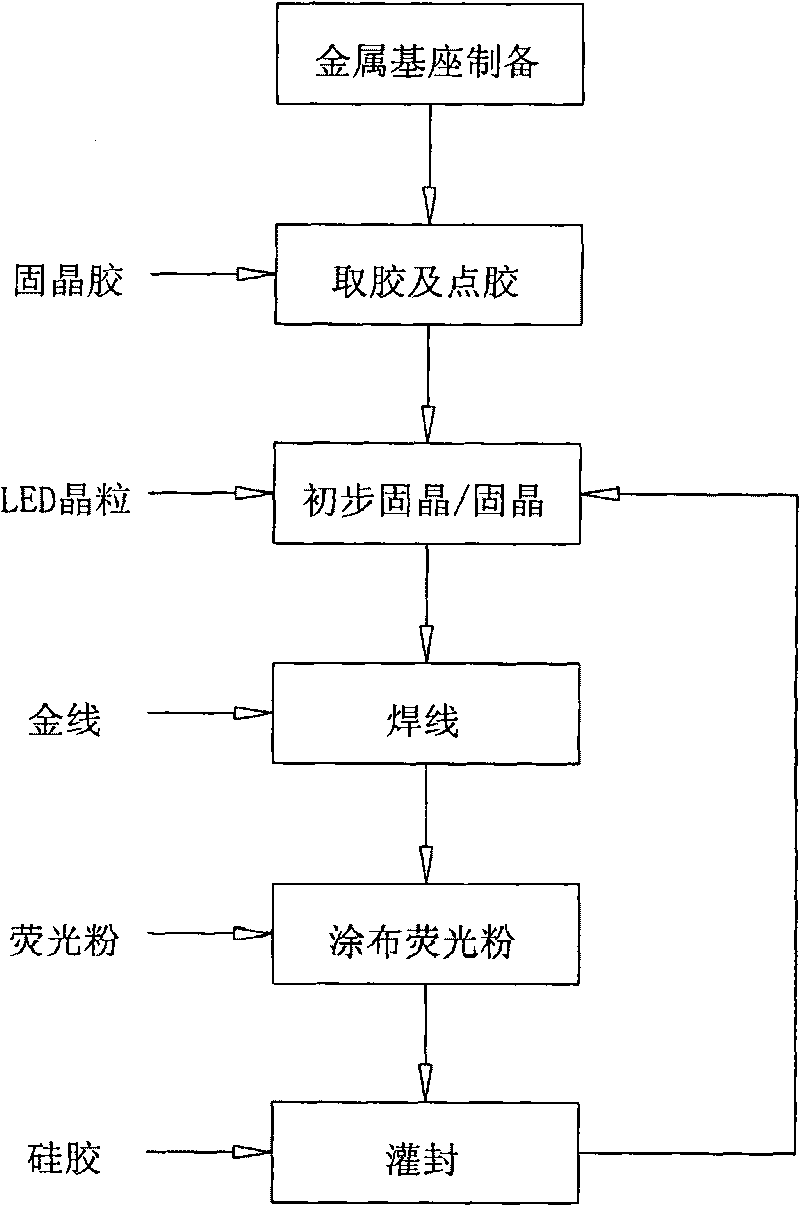

[0015] A method of bonding crystals to improve the light-emitting efficiency of LEDs, such as figure 1 The process shown includes: preparation of the metal base, glue removal and dispensing, preliminary die bonding, wire bonding, phosphor coating, and finally potting of silica gel for final die bonding. Wire bonding and phosphor coating are not steps for die bonding , but the entire process must be carried out step by step according to the above process, and the steps closely related to die bonding are described in detail below.

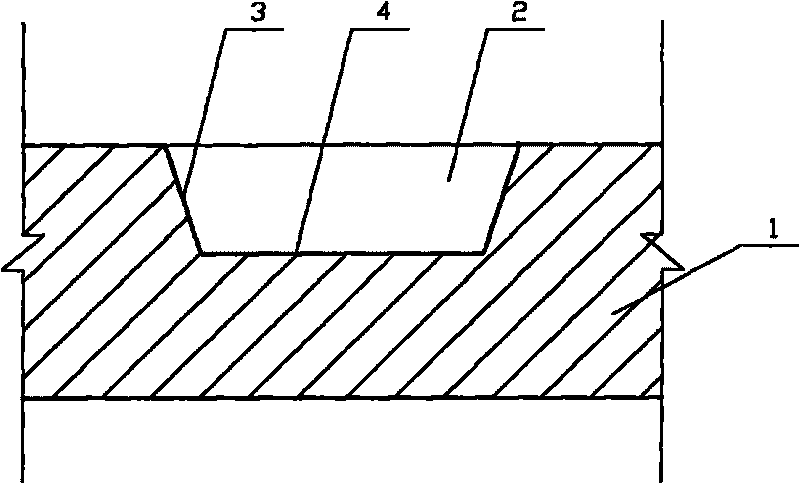

[0016] like figure 2 The metal base (1) is shown. The metal base is made of high thermal conductivity metal material, usually silver-plated on the surface of a copper plate. There are LED crystal grain fixing pits (2) arranged on the metal base, and the pits usually use a bell mouth shape, the inner surface of the bell mouth is polished and plated with a reflective layer (4), and the bottom surface of the pit is a solid crystal surface (4).

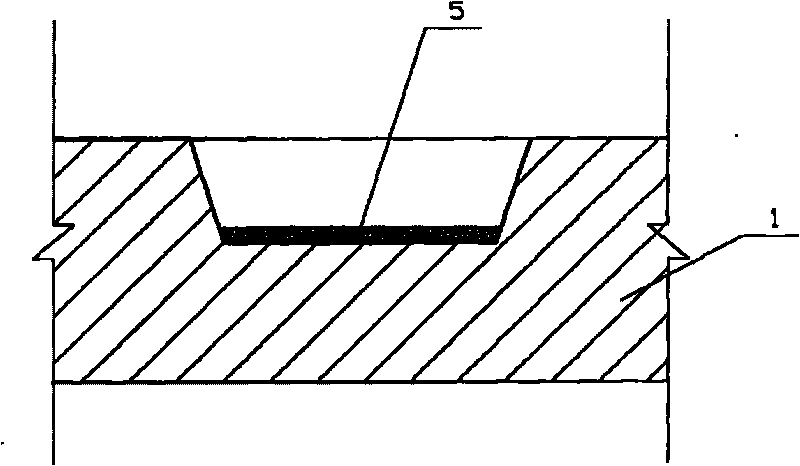

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com