Gan-based light-emitting diode with nanoscale silicon dioxide grating passivation layer and its processing method

A technology for light-emitting diodes and processing methods, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of external quantum efficiency and shortening of lifespan of light-emitting diodes, so as to improve light extraction efficiency, reduce current concentration, and reduce leakage current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical scheme of the present invention will be further explained below in conjunction with the drawings.

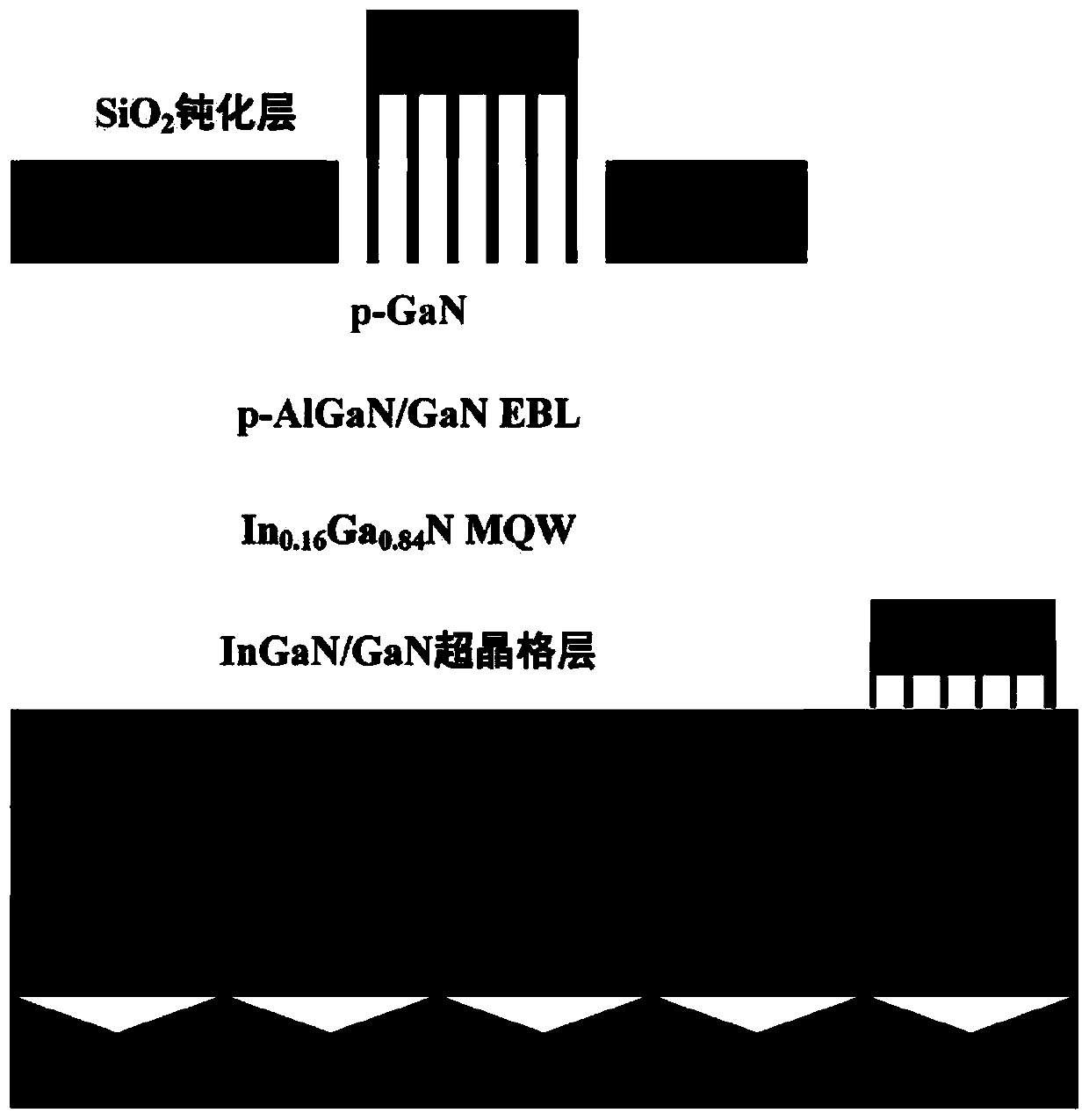

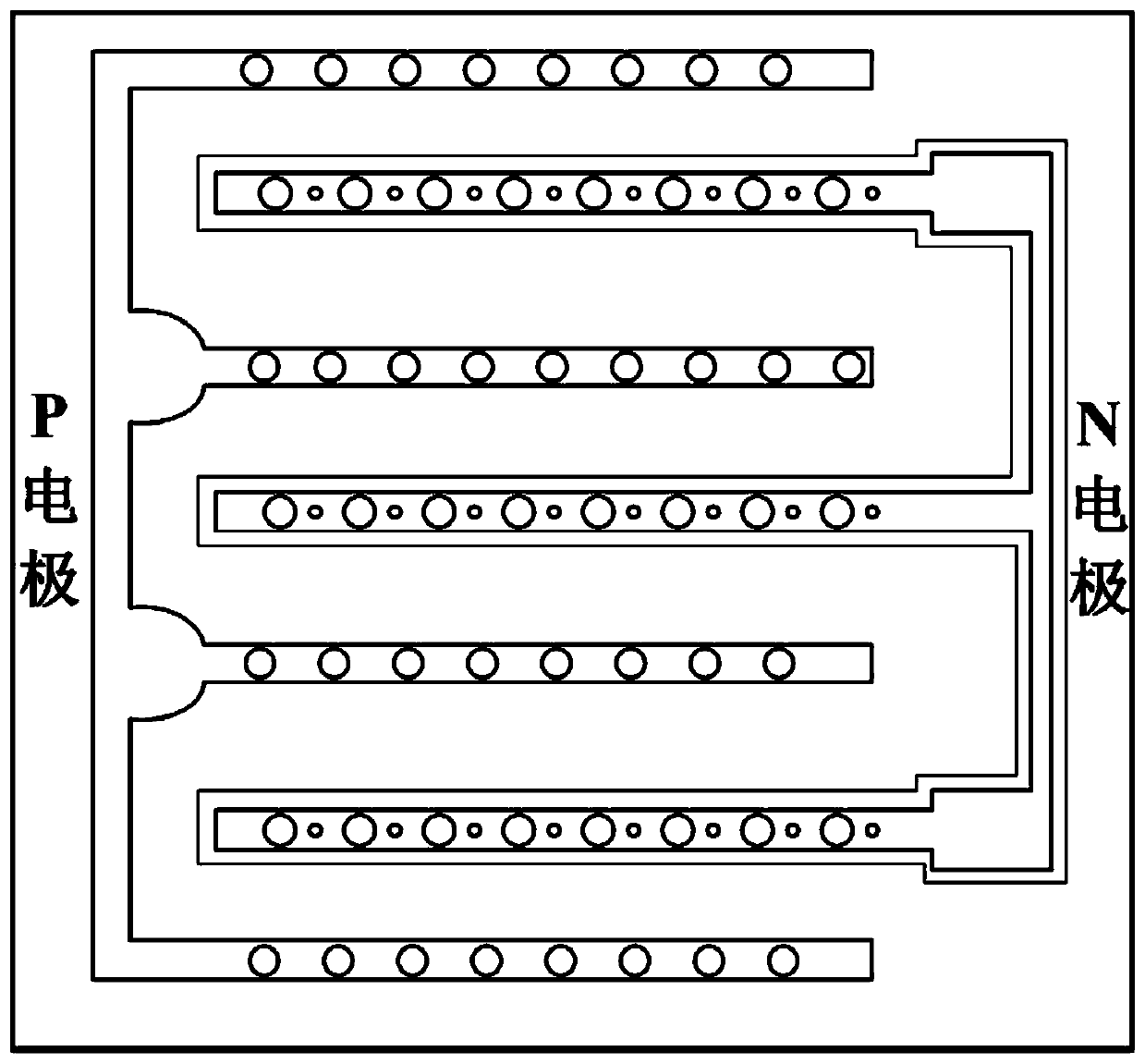

[0047] In this embodiment, GaN-based light-emitting diodes such as figure 1 As shown, it includes a patterned sapphire substrate 1, an AlN nucleation layer 2, a GaN buffer layer 3, an n-type GaN layer 4, an InGaN / GaN superlattice layer 5, In 0.16 Ga 0.84 N multiple quantum well layer 6, p-AlGaN / GaN electron blocking layer 7, p-type GaN layer 8, ITO layer 9, SiO 2 Passivation layer 10, P electrode and N electrode.

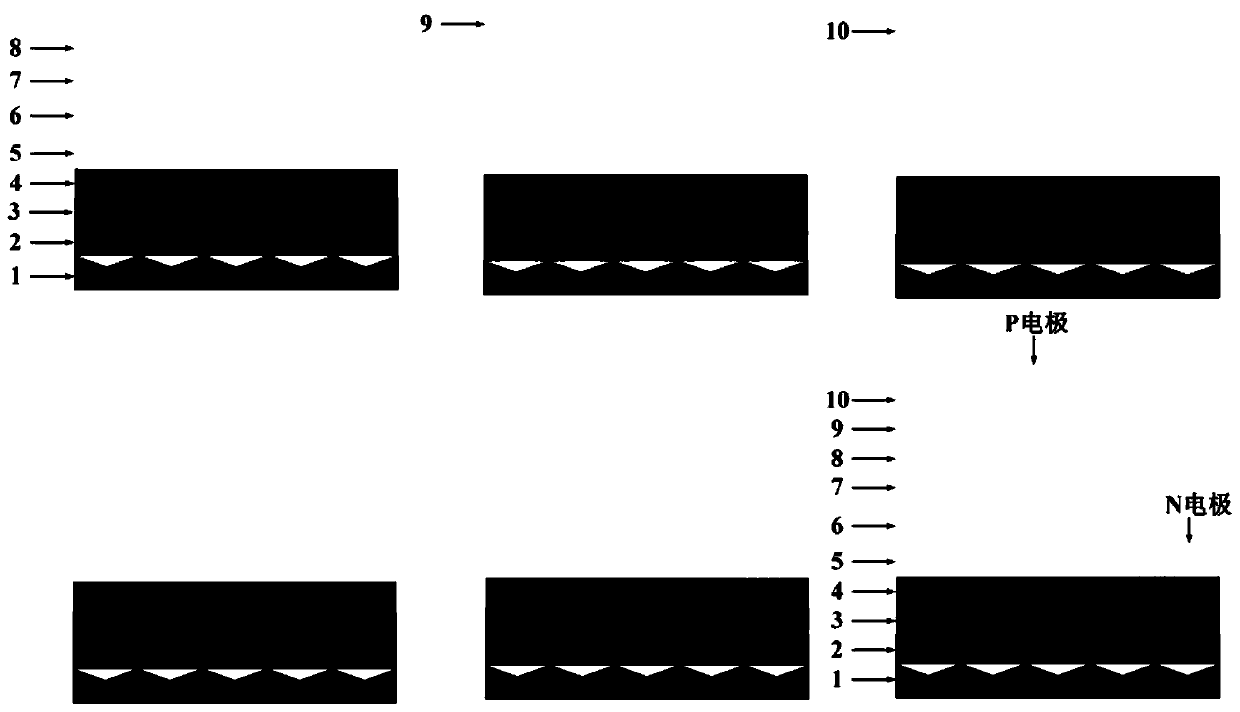

[0048] Reference to the manufacturing flow chart of the light emitting diode of the present invention figure 2 , The specific implementation steps are as follows:

[0049] (1) Place the cleaned c-plane patterned sapphire substrate 1 on a rotatable substrate;

[0050] (2) Draw the reaction chamber into 2.5×10 -3 Pa’s vacuum chamber, open to H 2 ;

[0051] (3) Under the condition of 1010℃, grow a 25nm thick AlN nucleation layer;

[0052] (4) At a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com