High-performance glass encapsulation method of light emitting diode

A light-emitting diode and glass encapsulation technology, which is applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor moisture resistance of organic matter, poor light transmission of lenses, and poor light transmission performance, so as to achieve anti-aging and simple and reliable process , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]Embodiment 1 A high-performance glass packaging method for light-emitting diodes, comprising the following steps: the first step is to prepare a glass package with a microcavity on the back and a microlens on the front on a glass wafer; the glass package is heated by negative pressure. Forming method preparation, the specific preparation method can be seen in Example 3-4, its size is slightly larger than the light-emitting diode (LED) chip that needs to be packaged, the LED lead wire can be made according to the conventional process, the second step, the phosphor powder coating process: the fluorescent powder Powder (YAG: ce3+) mixed with silica gel (Jiuqi brand WH-7 type silicone sealant produced by Nanjing Helite Adhesive Co., Ltd.). The coverage area and thickness are determined, that is, the product of the area and the thickness is the volume to be coated and evenly coated on the surface of the LED chip to form a phosphor layer. The thickness can be selected according...

Embodiment 2

[0028] Embodiment 2 A high-performance glass encapsulation method for light-emitting diodes, comprising the following steps:

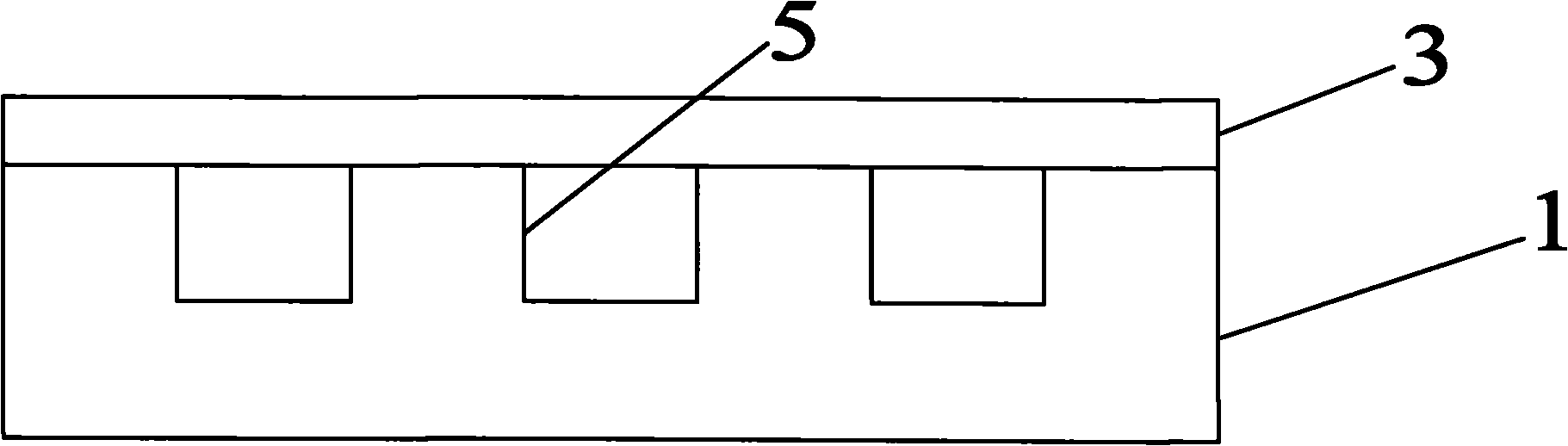

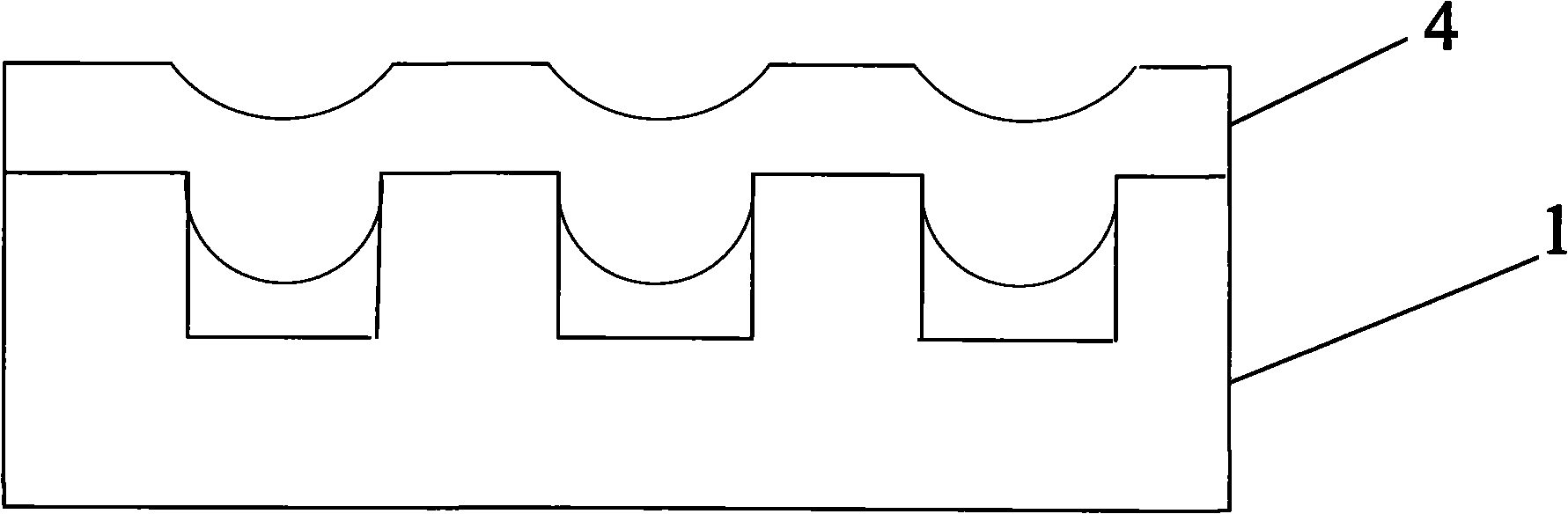

[0029] The first step is to prepare a glass lens array for sealing light-emitting diode (LED) chips on Pyrex7740 glass; when the glass is melted, it is sunken to the silicon microgroove to form a convex lens with a thick middle and thin surroundings, and a microcavity is formed under the lens at the same time, which can A light emitting diode (LED) chip is placed and sealed in the microcavity under the glass lens. For the preparation method of the glass lens microcavity, see the following embodiments of the present invention. The following examples of the present invention describe the method of making glass lenses by negative pressure forming. The glass microcavity prepared by the method described in the embodiment behind this embodiment adopts different microgroove aspect ratios, and the time and temperature of glass molding also adopt different val...

Embodiment 3

[0033] Embodiment 3 Manufacturing method of wafer-level glass lens microcavity

[0034] A method for manufacturing a wafer-level glass lens microcavity, comprising the following steps:

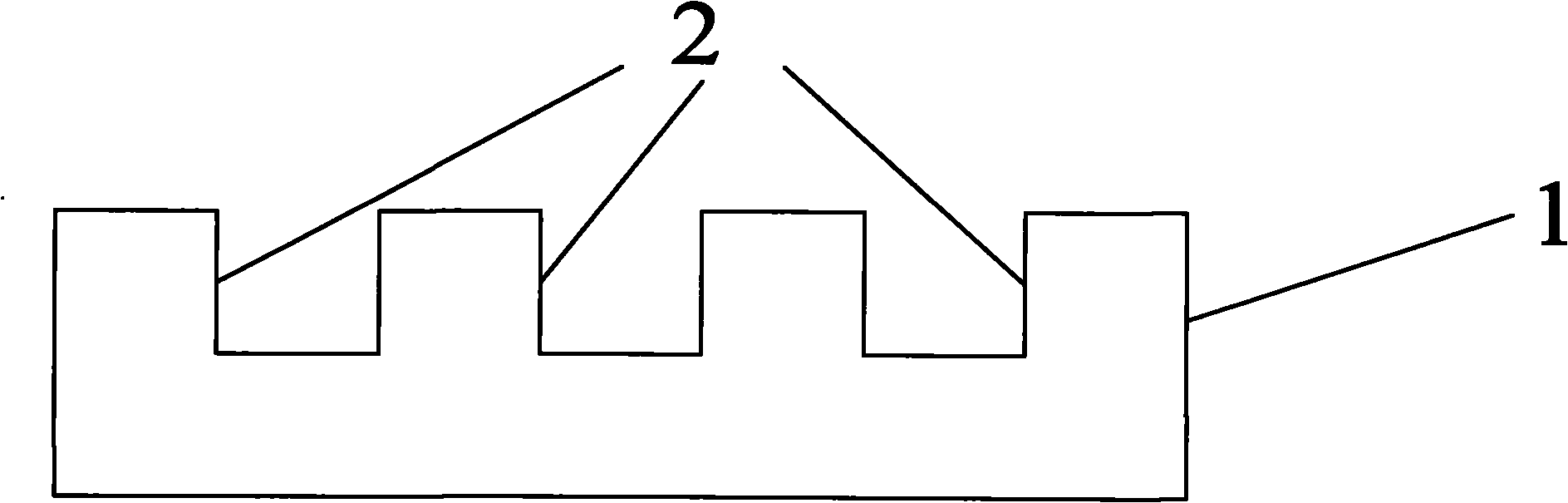

[0035] In the first step, a specific pattern is formed on an Si wafer (such as a 4-inch wafer) by etching using a Si micromachining process, and the micromachining process of the pattern structure on the Si wafer is a wet etching process or a dry inductively coupled plasma One of the bulk (ICP) etching process, reactive ion etching or deep reactive ion etching, the pattern can be a square or circular groove array, or a number of different graphics, (in fact, three-dimensionally, Engraving a specific pattern is to carve a groove on a silicon wafer, which is a pattern in two dimensions), and the aspect ratio of the microgroove can be less than 1:1 or greater than 1:1, for example: 2:1, 3:1, 4:1 , 7:1, 10:1, 15:1, 20:1, 25:1, the glass microcavity with high aspect ratio will provide more rheolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com