Self-indicating patch semiconductor laser and packaging method thereof

A packaging method and chip packaging technology, applied in the direction of semiconductor lasers, lasers, laser parts, etc., can solve the problems of affecting stability, equipment failure, high structure, etc., to achieve flattening and miniaturization, and reduce the distance of the optical path. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

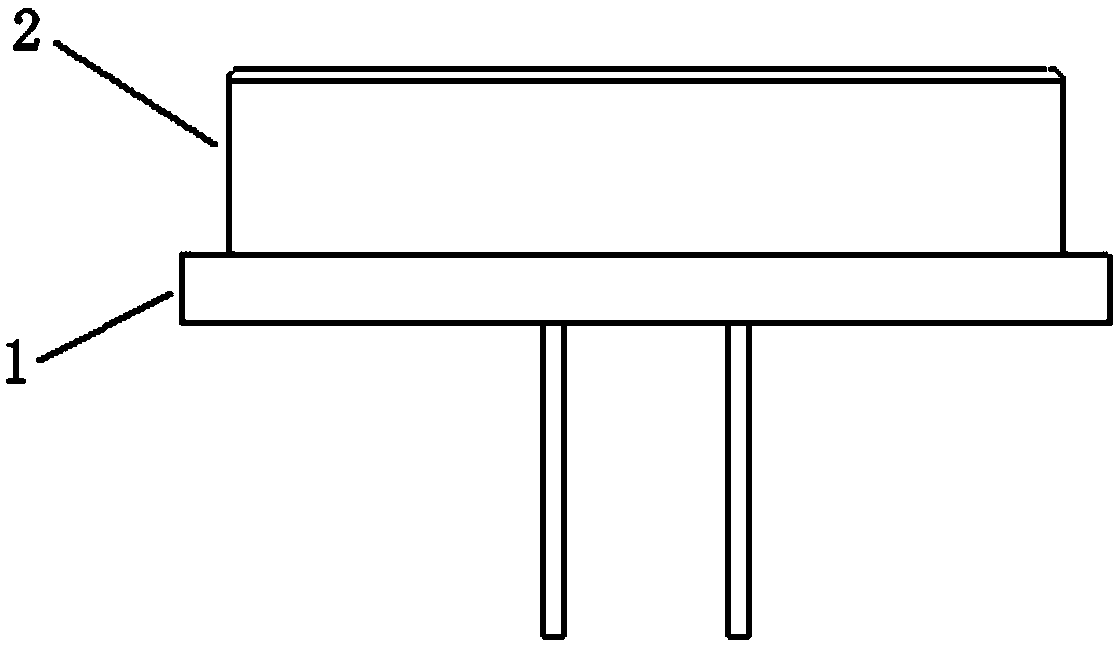

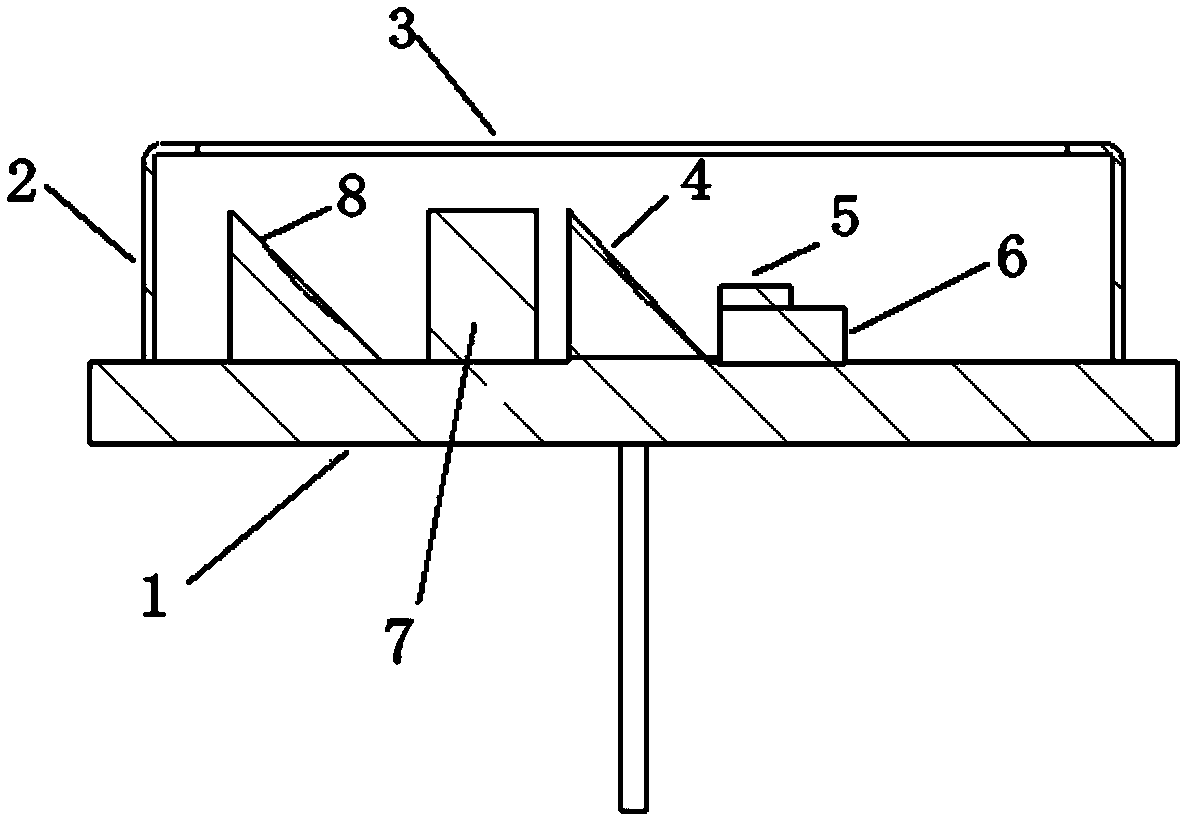

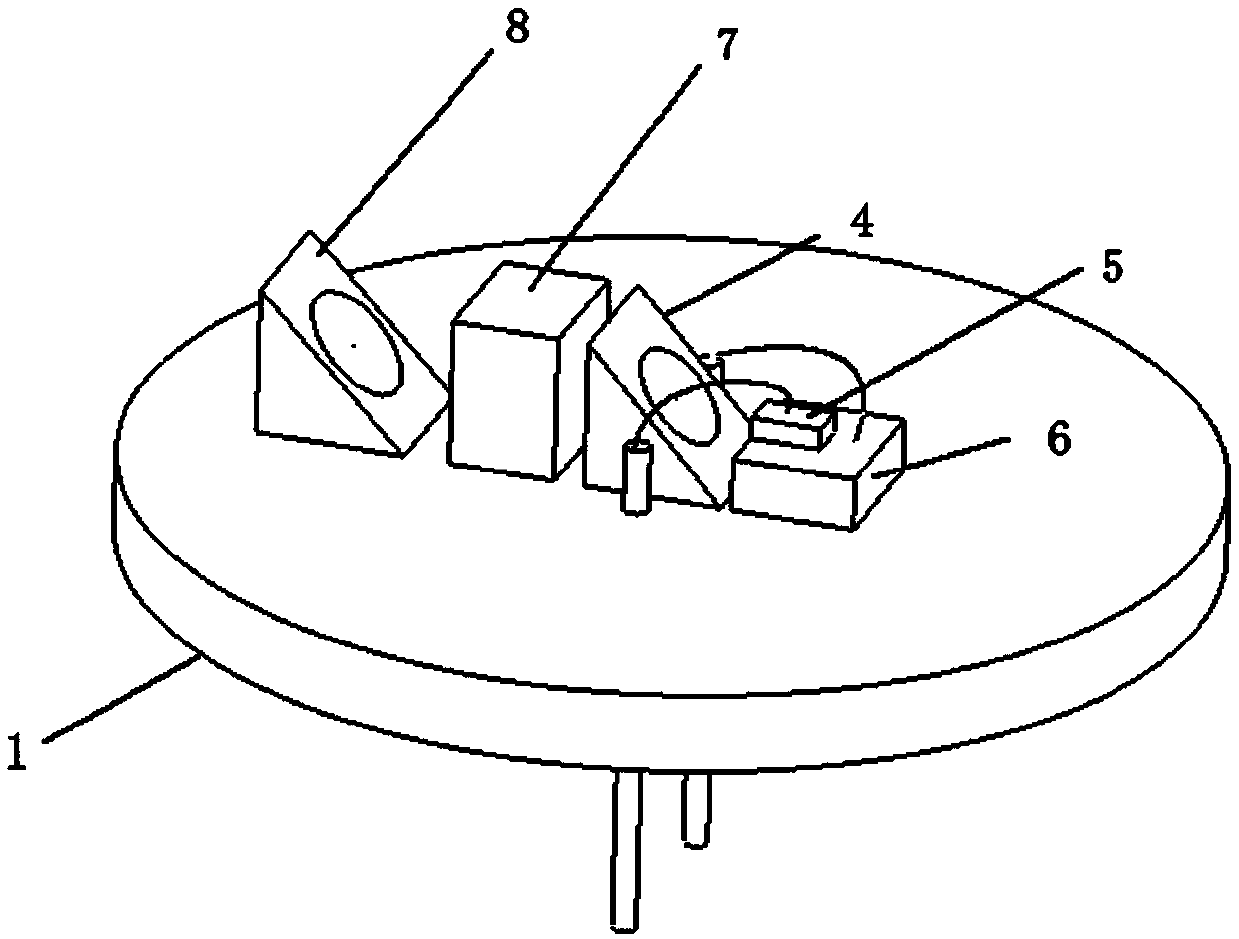

[0051] A self-indicating chip semiconductor laser, including a tube base 1 and a tube cap 2 arranged on the tube base 1, the overall appearance schematic diagram is as follows figure 1 shown. In the space formed by the tube base 1 and the tube cap 2, COS, a 45° right-angle semi-reflection table 4, a crystal 7, and a 45° right-angle total reflection table 8 are sequentially arranged on the tube base 1 along the optical path; the cross-sectional schematic diagram is as follows figure 2 shown. The schematic diagram of the structure before capping is as follows: image 3 shown.

[0052] The 45° right-angle semi-reflective table 4 is coated with an 808nm semi-permeable film on the reflective surface. The transmittance and reflectivity can be adjusted by adjusting the coating, so that 50% of the 808nm laser emitted by the die 5 can be emitted horizontally and 50% of the light can be changed. The light path exits vertically. There is a crystal 7 on the optical path, which makes ...

Embodiment 2

[0054] According to the self-indicating chip semiconductor laser described in Embodiment 1, the difference is that the COS includes a heat sink 6 and a die 5 sintered on the heat sink 6 , and the die 5 is flip-chip mounted on the heat sink 6 . The heat emitted by the tube core 5 can be dissipated faster. The solder used for bonding the die 5 of the laser is gold-tin solder, which has the characteristics of high strength, good oxidation resistance, excellent thermal fatigue and creep resistance, low melting point, and good fluidity. The heat sink 6 is an insulating heat sink. Make the shell uncharged to reduce the probability of electrostatic breakdown of the laser in subsequent applications. The COS parallel patch is on the base 1. The overall vertical height of the laser is reduced by about 2 mm, which makes the structure flat and meets the application of some flat spaces. The material used is silver glue. There is a COS positioning groove on the tube base 1, which is con...

Embodiment 3

[0056] A self-indicating chip semiconductor laser according to embodiment 1 or 2, the difference is that,

[0057] The tube base 1 is different from the ordinary TO tube base. The tube base 1 does not have the tongue of the conventional tube base, which shortens the vertical length of the laser, makes the structure flat, and can adapt to the application of relatively narrow space.

[0058] The crystal 7 is Nd:YVO4 crystal or KTP crystal, and the crystal 7 is fixed on the stem 1 by optical ultraviolet glue. Curing is quick and easy to handle.

[0059] The cap 2 is provided with a coating window 3 . The enhanced transmittance of the laser can be increased. The tube cap 2 is sealed in a nitrogen environment during the packaging process, so that the laser works in an oxygen-free environment to reduce oxidation of the laser, and the airtight space can also prevent dust.

[0060] The material of 45° right-angle semi-reflection table 4 and 45° right-angle total reflection table 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com