LED chip electrode and fabrication method thereof

A technology of LED chip and manufacturing method, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of voltage rise, affecting luminous efficiency, and easy detachment of electrodes, etc., to achieve improved luminous efficiency, increased emission rate, and high brightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

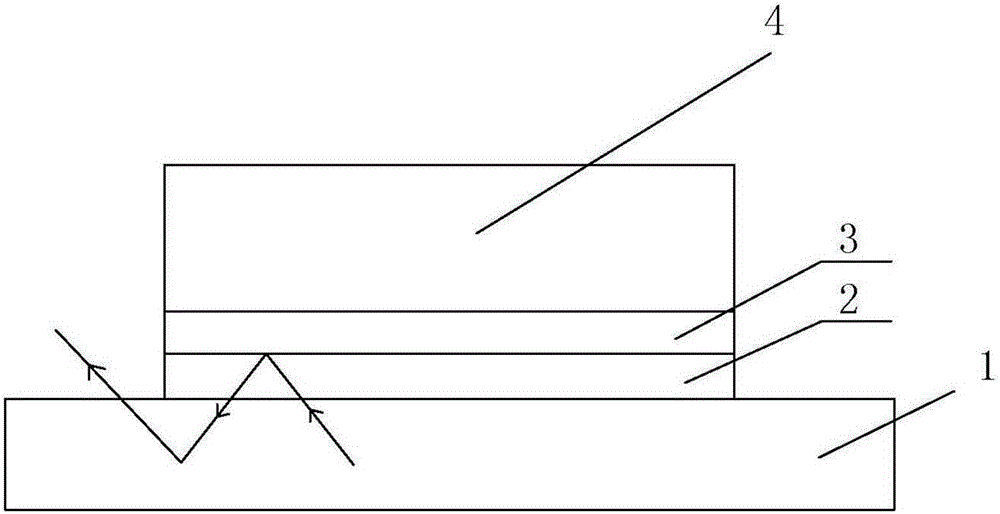

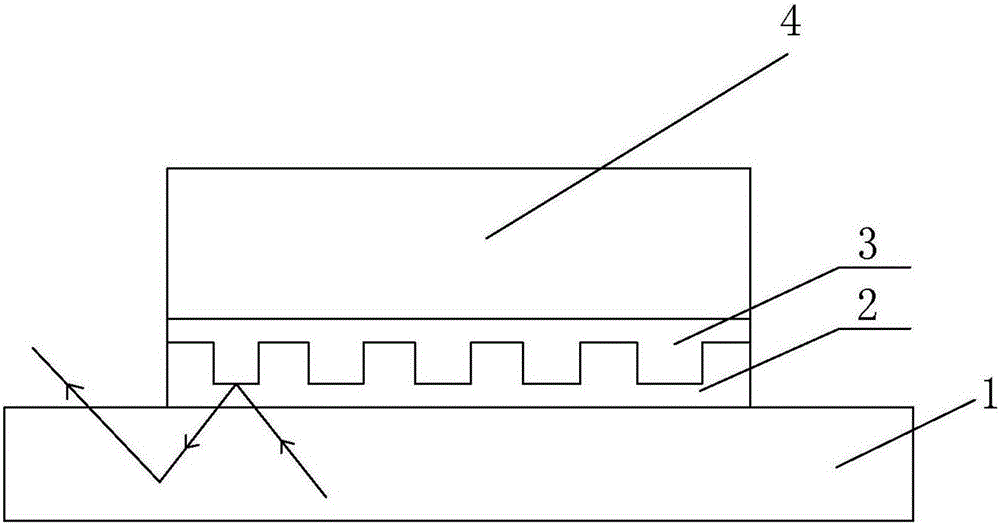

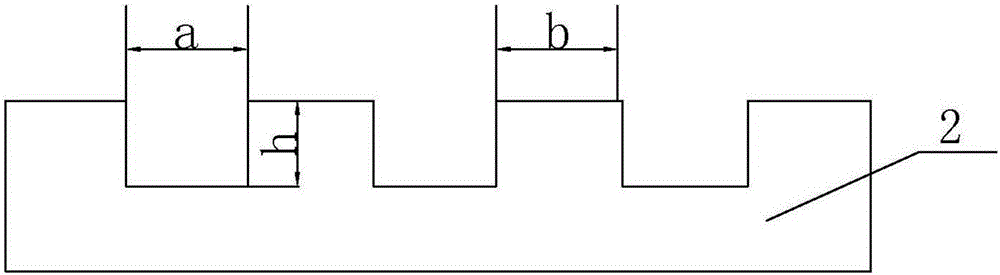

[0033] to combine Figure 2-Figure 9 , the present embodiment provides a method for manufacturing an electrode of an LED chip, comprising the steps of:

[0034] Step 101: The dry etching equipment ICP etches the epitaxial layer 1 including the N-type GaN layer, the quantum well, and the P-type GaN layer from bottom to top, forming steps to expose the N-type GaN layer, with an etching depth of 1 μm, and cutting lines The width is between 10 μm, the P electrode is made on the P-type GaN layer, and the N electrode is made on the N-type GaN layer;

[0035] Step 102: Electron beam vacuum evaporation method is used to make the conductive layer of indium tin oxide film, and the film thickness is , chamber temperature 150°C, oxygen flow rate 5sccm, vacuum degree 3×10 -5 Torr;

[0036] Step 103: if Figure 4 As shown, a negative photoresist 5 with a thickness of 2.5 μm is coated, exposed and developed to expose the electrode region;

[0037] Step 104: if Figure 5 As shown, the ...

Embodiment 2

[0046] combine Figure 2-Figure 9 , the present embodiment provides a method for manufacturing an electrode of an LED chip, comprising the steps of:

[0047] Step 201: The dry etching equipment ICP etches the epitaxial layer 1 including the N-type GaN layer, the quantum well and the P-type GaN layer from bottom to top, forming steps to expose the N-type GaN layer, with an etching depth of 2 μm, and cutting lines The width is between 25 μm, the P electrode is made on the P-type GaN layer, and the N electrode is made on the N-type GaN layer;

[0048] Step 202: Electron beam vacuum evaporation method is used to make the conductive layer of indium tin oxide film, and the film thickness is , chamber temperature 350°C, oxygen flow rate 15sccm, vacuum degree 3×10 -7 Torr;

[0049] Step 203: if Figure 4 As shown, a negative photoresist 5 with a thickness of 3.0 μm is coated, exposed and developed to expose the electrode region;

[0050] Step 204: if Figure 5 As shown, the ele...

Embodiment 3

[0059] combine Figure 2-Figure 9 , the present embodiment provides a method for manufacturing an electrode of an LED chip, comprising the steps of:

[0060] Step 301: The dry etching equipment ICP etches the epitaxial layer 1 including the N-type GaN layer, the quantum well and the P-type GaN layer from bottom to top in order to form steps to expose the N-type GaN layer, the etching depth is 1.5 μm, and the cutting line The width is between 17 μm, the P electrode is made on the P-type GaN layer, and the N electrode is made on the N-type GaN layer;

[0061] Step 302: making an indium tin oxide thin film conductive layer by electron beam vacuum evaporation method, the film thickness is The chamber temperature is 250°C, the oxygen flow rate is 10sccm, and the vacuum degree is 5.05×10 -6 Torr;

[0062] Step 303: if Figure 4 As shown, a negative photoresist 5 with a thickness of 2.7 μm is coated, exposed and developed to expose the electrode region;

[0063] Step 304: if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com