Plastic optical reflector for downlight with microlens array on surface

A microlens array and optical reflection technology, applied in the field of reflectors, can solve the problems of reducing diffuse reflection efficiency, limiting wide application, optical energy dissipation, etc., to achieve the effects of improving energy utilization, increasing irradiation area, and reducing glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

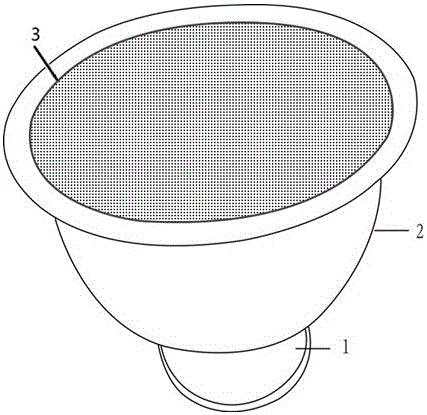

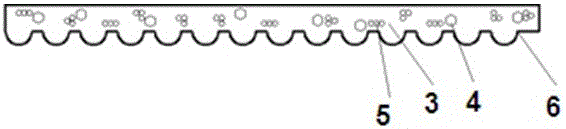

[0024] Such as figure 1 with figure 2 As shown, the plastic optical reflector for downlights with a microlens array on the surface of the present invention includes a light distribution port 1 and a light distribution cover 2, the light distribution port 1 is fixed on the bottom end of the light distribution cover 2, and the light distribution cover 2 is provided with Microlens Array Structure 3. The plastic optical reflector for downlights with a microlens array on the surface can be doped with light-reflecting particles 5 and ultraviolet absorbers 4, and the doping amounts of light-reflective particles and ultraviolet absorbers accounted for 5% and 0.5% by weight of the reflector respectively. %. The microlens array structure is a hemispherical structure 6 arranged in a rectangle, with a radius of 0.1 mm and a distance between centers of the spheres of 0.4 mm.

[0025] The material of the reflector is HIPS (high impact polystyrene), accounting for 93.82% by weight; the m...

Embodiment 2

[0027] The main difference between embodiment 2 and embodiment 1 is that the arrangement pitch of the prisms is different, the radius of the prisms is 0.1 mm, and the pitch between the centers of the prisms is 0.2 mm.

Embodiment 3

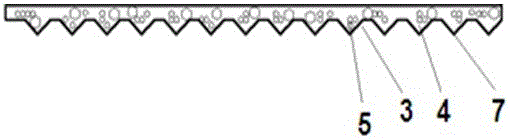

[0029] Such as image 3 As shown, the main difference between embodiment 3 and embodiment 1 is that the microlens array structure in embodiment 3 is prism structure 7, and the prism structure 7 is arranged in a rectangle, and the length of each side of the prisms is 0.1 mm, and the distance between centers is 0.4 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com