A kind of paint and its preparation method and application

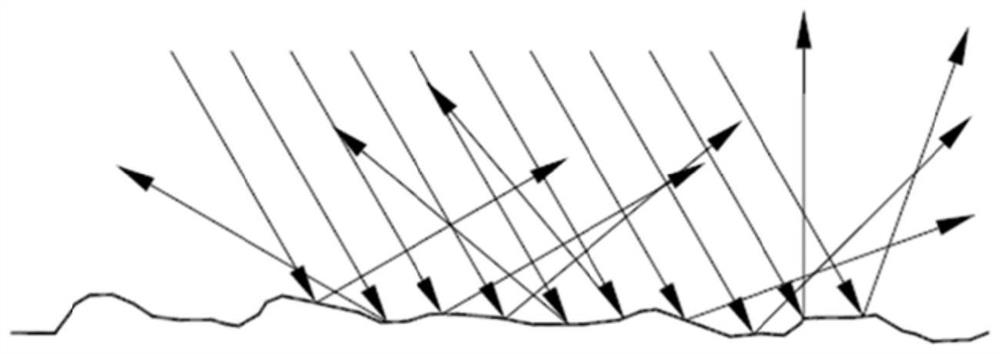

A paint and visible light technology, applied in the field of paint, can solve the problems of inability to apply large-scale industrial production and decorative panels of large buildings, chemical corrosion resistance, safety hazards and other problems, achieve good light color consistency, easy processing and molding, The effect of reducing light energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 paint and preparation method thereof

[0027] 1. Paint components (by weight):

[0028] 42 parts of saturated polyester resin, 7 parts of permethyletherified amino resin, 32 parts of titanium dioxide, 0.6 parts of leveling agent, 0.6 parts of defoamer, 0.6 parts of acid catalyst, 5 parts of fumed silica, and 13 parts of solvent.

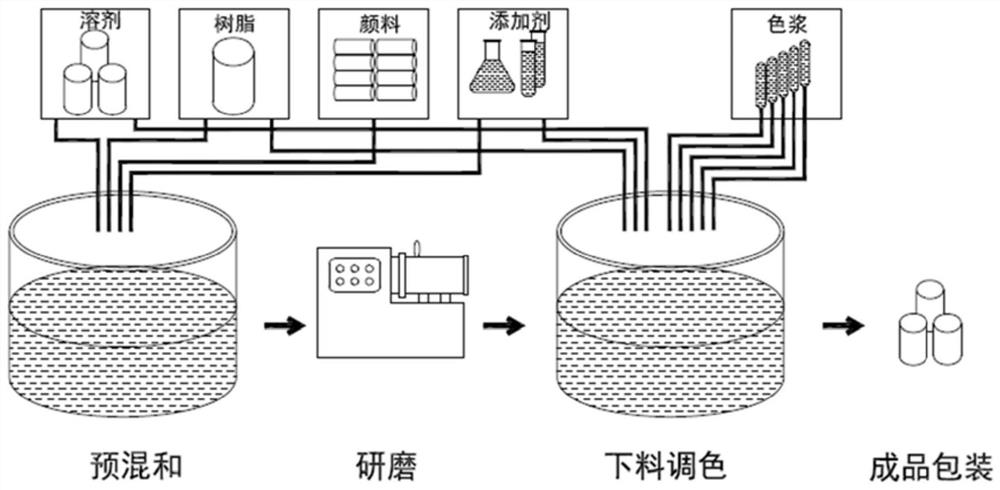

[0029] 2, the preparation method of above-mentioned paint is as follows (also can refer to figure 1 ):

[0030] (1) Preparation of color paste: Mix 20 parts by weight of resin and 6 parts by weight of 150# solvent at room temperature, stir evenly under no-pressure conditions, add pigment at a uniform speed while stirring, and continue stirring after the addition is completed. Between 1-2 hours, the fineness of the mixture reaches within 20 microns;

[0031] (2) Addition of acid catalyst: Add the remaining 29 parts by weight of resin and 7 parts by weight of 150# solvent in the color paste prepared by step (1), and then add 0.6 ...

Embodiment 2

[0032] Embodiment 2 performance parameter

[0033]The paint in Example 1 is coated on the aluminum honeycomb panel, and the light diffuse reflection aluminum honeycomb panel is sent to the National Building Materials Testing Center for testing (test center number: WT2018B01B00300 mid-term-2), and the monitoring results are as follows: decorative surface Layer thickness: average value 68μm, minimum value 65μm, visible light reflectance (including specular reflection) is 96%, visible light reflectance (specular reflection removal) is 95%, 550nm reflectance (specular reflection removal) is 95%, other indicators : Appearance quality, dimensional tolerance, aluminum plate thickness, coating flexibility, coating adhesion, coating hydrochloric acid resistance, coating oil resistance, coating alkali resistance, coating nitric acid resistance, roller peel strength, flat pull Strength, flat compression strength, flat compression elastic modulus, plane shear strength, plane shear elastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com