Producing method for graphical sapphire substrate

A technology of sapphire substrate and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as increased leakage current, increased epitaxial growth cycle, lattice mismatch, etc., to increase lateral epitaxial growth, reduce Epitaxial growth cycle, the effect of increasing the probability of exit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

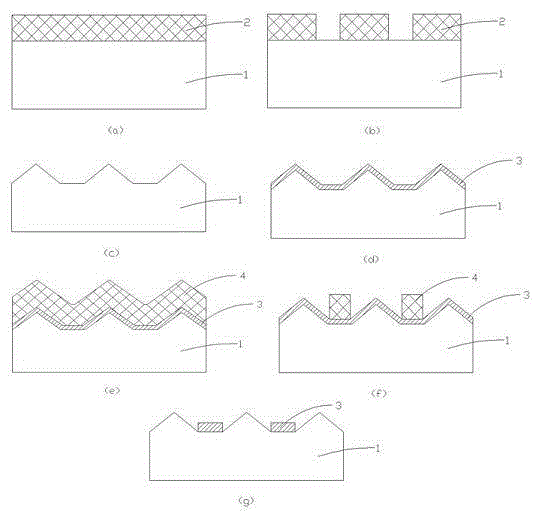

[0048] This embodiment combines figure 1 As shown, this embodiment adopts a patterned substrate obtained by a dry method.

[0049] 1. Provide a flat sapphire substrate 1 with a first layer of photoresist 2 of 2.5 μm on its surface, such as figure 1 as shown in (a);

[0050] 2. Use photolithography technology to expose the first layer of photoresist 2, and form such as figure 1 the graph shown in (b);

[0051] 3. Using the ICP process, using boron trichloride gas to etch a pattern on the surface of the substrate 1, remove the remaining first layer of photoresist 2, and form such as figure 1 (c) the graph shown;

[0052] 4. Deposit 200nm silicon dioxide 3 on the surface of the patterned substrate 1 by plasma enhanced chemical vapor deposition, such as figure 1 as shown in (d);

[0053] 5. Utilize photolithography technology to expose the second layer of photoresist 4, and form such as figure 1 (f) the graph shown;

Embodiment 2

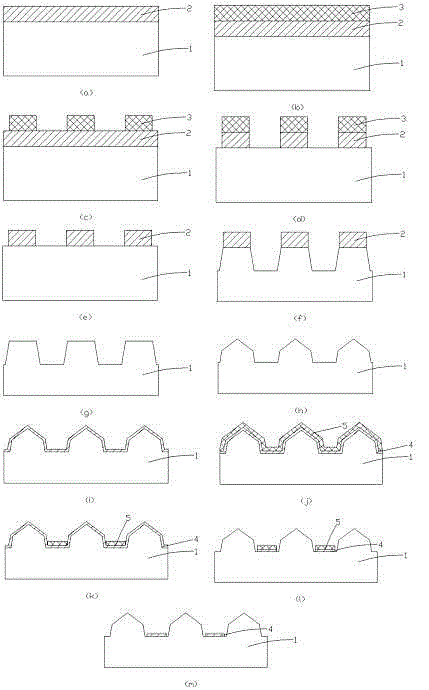

[0056] This embodiment combines figure 2 As shown, this embodiment uses a patterned substrate obtained by a wet method.

[0057] 1. A flat sapphire substrate 1 is provided, and a first layer of silicon dioxide 2 of 100 nm is deposited on its surface by plasma-enhanced chemical vapor deposition, such as figure 2 as shown in (a);

[0058] 2. Use photolithography to expose the photoresist to form such as figure 2 The graph shown in (c), the detailed process see figure 2 (b) and 2(c);

[0059] 3. Etch the first layer of silicon dioxide 2 to obtain such figure 2 The graph shown in (e), the specific process is detailed in figure 2 (d) and 2(e);

[0060] 4. Use 270°C, soak in the mixed acid solution of phosphoric acid: sulfuric acid = 1:3 for a certain period of time, and obtain the following figure 2 The pattern shown in (g), then remove the first layer of silicon dioxide 2 on the surface, and keep the first layer of photoresist 3, the specific process is detailed in f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com