LED graphic optimized packaging substrate, LED packaging member and manufacture method thereof

A technology for packaging substrates and LED chips, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of inability to change the light propagation path, and achieve the effects of reliable design indicators, improved light extraction efficiency, and improved extraction probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

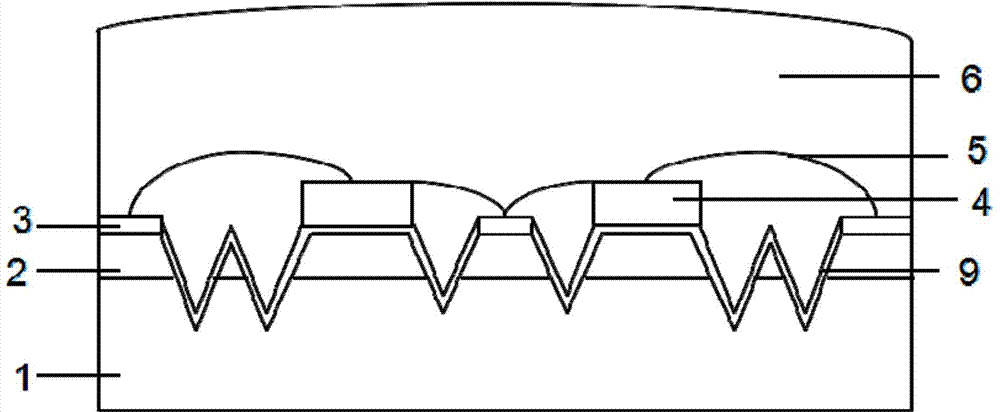

[0038] Such as figure 1 As shown, the LED package of this embodiment includes a package substrate 1 optimized for LED graphics, on which a copper film electrode 3 and an LED chip 4 are arranged, and the positive and negative poles of the copper film electrode 3 and the LED chip 4 pass through The gold wires 5 are connected; the LED chips are packaged on the packaging substrate by COB packaging technology, and the LED chips are covered with an encapsulant 6; the LED chips are arranged periodically and regularly in a rectangular array.

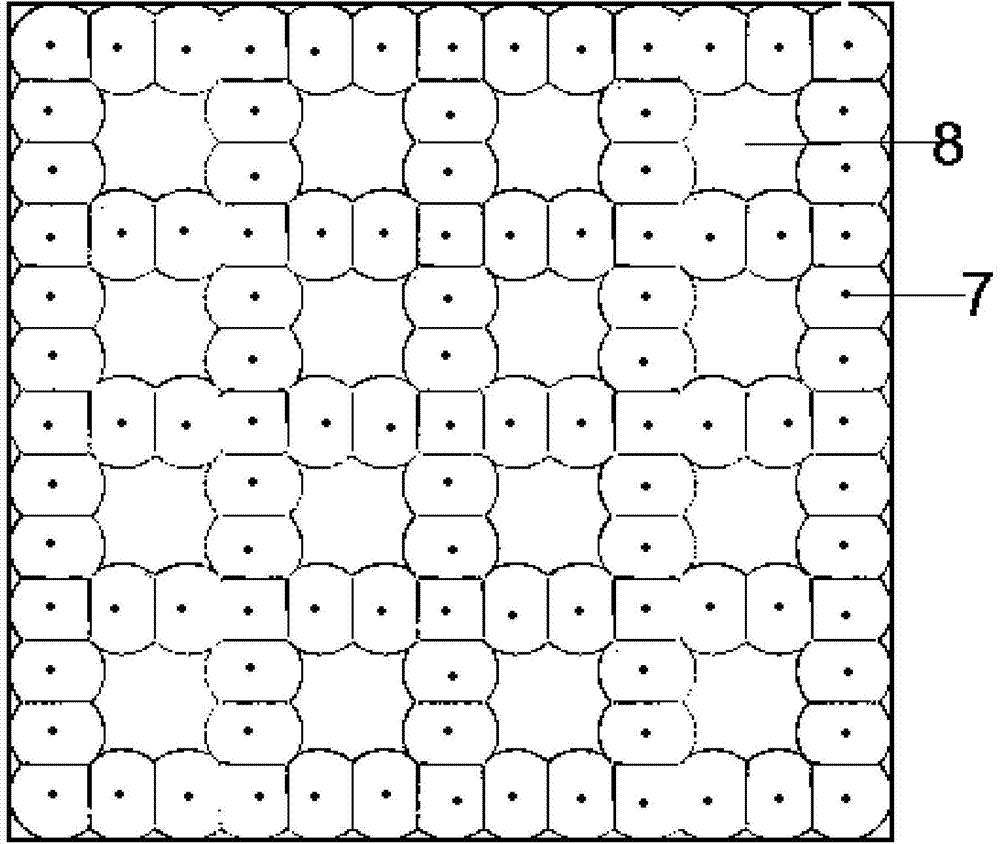

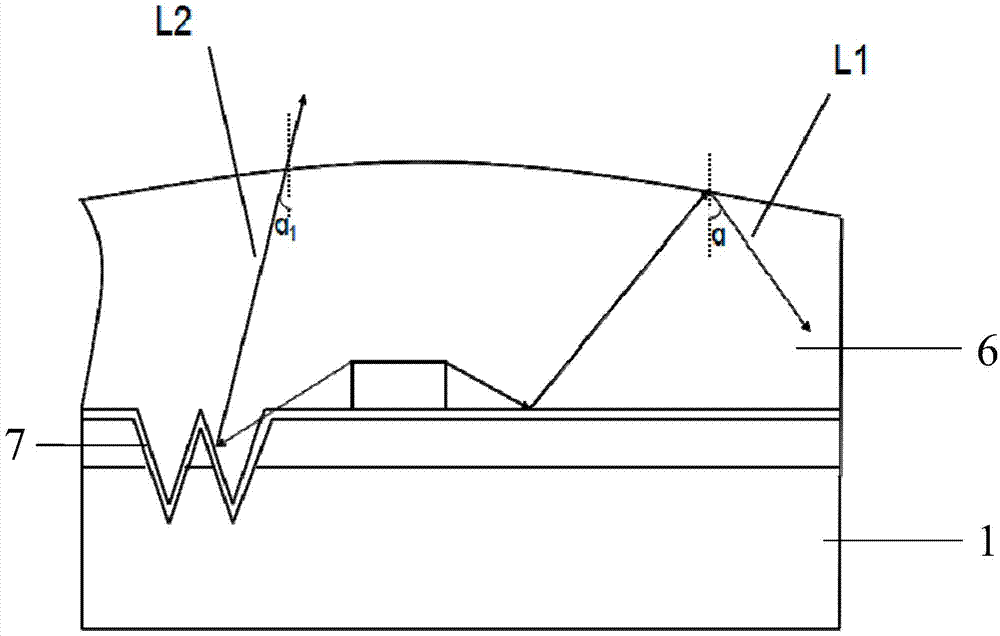

[0039] Such as Figure 2~3 As shown, the LED graphics optimization packaging substrate 1 of the present embodiment is provided with an inverted conical groove pattern, except for the position (LED chip platform 8) reserved for installing LED chips on the packaging substrate, the inverted conical groove 7 adopts a rectangular shape. The array is periodically and regularly arranged; the horizontal surface of the packaging substrate is coated with...

Embodiment 2

[0048] The LED package of this embodiment includes an AlSiC packaging substrate optimized for LED graphics, on which a copper film electrode and an LED chip are arranged, and the positive and negative poles of the copper film electrode and the LED chip are connected by a gold wire; the LED The chip is encapsulated on the packaging substrate by COB packaging technology, and the LED chip is covered with an encapsulant; the LED chips are arranged periodically and regularly in a rectangular array.

[0049] Such as Figure 4 As shown, the LED graphic optimization packaging substrate of this embodiment is provided with inverted conical grooves 7, except for the position (LED chip platform 8) reserved for mounting LED chips on the packaging substrate, the inverted conical grooves are formed in a rectangular array. Periodic and regular arrangement; the horizontal surface of the packaging substrate is coated with a diamond-like carbon insulating layer; the horizontal surface of the pac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base radius | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com