Organic electroluminescent displayer and manufacturing method thereof

A manufacturing method and technology of an organic light-emitting layer, applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, circuits, etc., can solve the problems of reducing the luminous efficiency of OLED displays, and achieve the goals of improving luminous efficiency, preventing color mixing, and reducing total reflection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

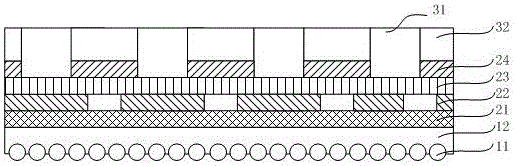

[0043] Embodiment 1 of the present invention provides an organic electroluminescent display, hereinafter referred to as an OLED display.

[0044] An OLED display may include a driving unit and a panel. The driving unit may include a timing controller, a scan driver and a data driver. A panel may include pixels. The pixels may be arranged in a basic matrix pattern. The pixels can be controlled in different ways and can emit light in different ways to display images across the entire surface of the panel. A pixel may include an organic light emitting layer and a thin film transistor. The organic light emitting layer may emit light by itself. The thin film transistor can drive the organic light emitting layer and control the brightness of the organic light emitting layer. The thin film transistor can control the pixel to receive or not receive the data signal in response to the scan-on voltage of the scan signal, thereby controlling the brightness of the organic light emitti...

Embodiment 2

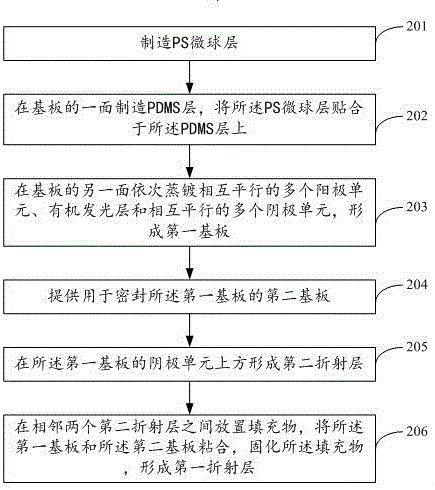

[0071] Embodiment 2 of the present invention provides a method for manufacturing an organic electroluminescent display according to Embodiment 1, such as figure 2 As shown, the method includes:

[0072] 201. Manufacturing PS microsphere layer 11;

[0073] Wherein, the PS microsphere layer 11 is a single-layer structure composed of PS microspheres. This step specifically includes:

[0074] 2011. Dissolving the PS microsphere raw material into ethanol to form a mixed solution, and dropping the mixed solution into water to form a suspension;

[0075] 2012. Clean the carrier sheet, soak the carrier sheet in hydrogen peroxide solution for 3 minutes, dry, dry or treat with plasma;

[0076] 2013. Put the carrier sheet into the petri dish, add water to the petri dish, drop the suspension of PS microspheres on the surface of the water to form a single layer of PS microspheres;

[0077] In 2014, using the vertical deposition method, the carrier sheet was slowly pulled out of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com