Novel fully passivated contact crystalline silicon solar cell and preparation method thereof

A technology for solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of large parasitic optical absorption loss, large resistivity of hydrogenated microcrystalline silicon oxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

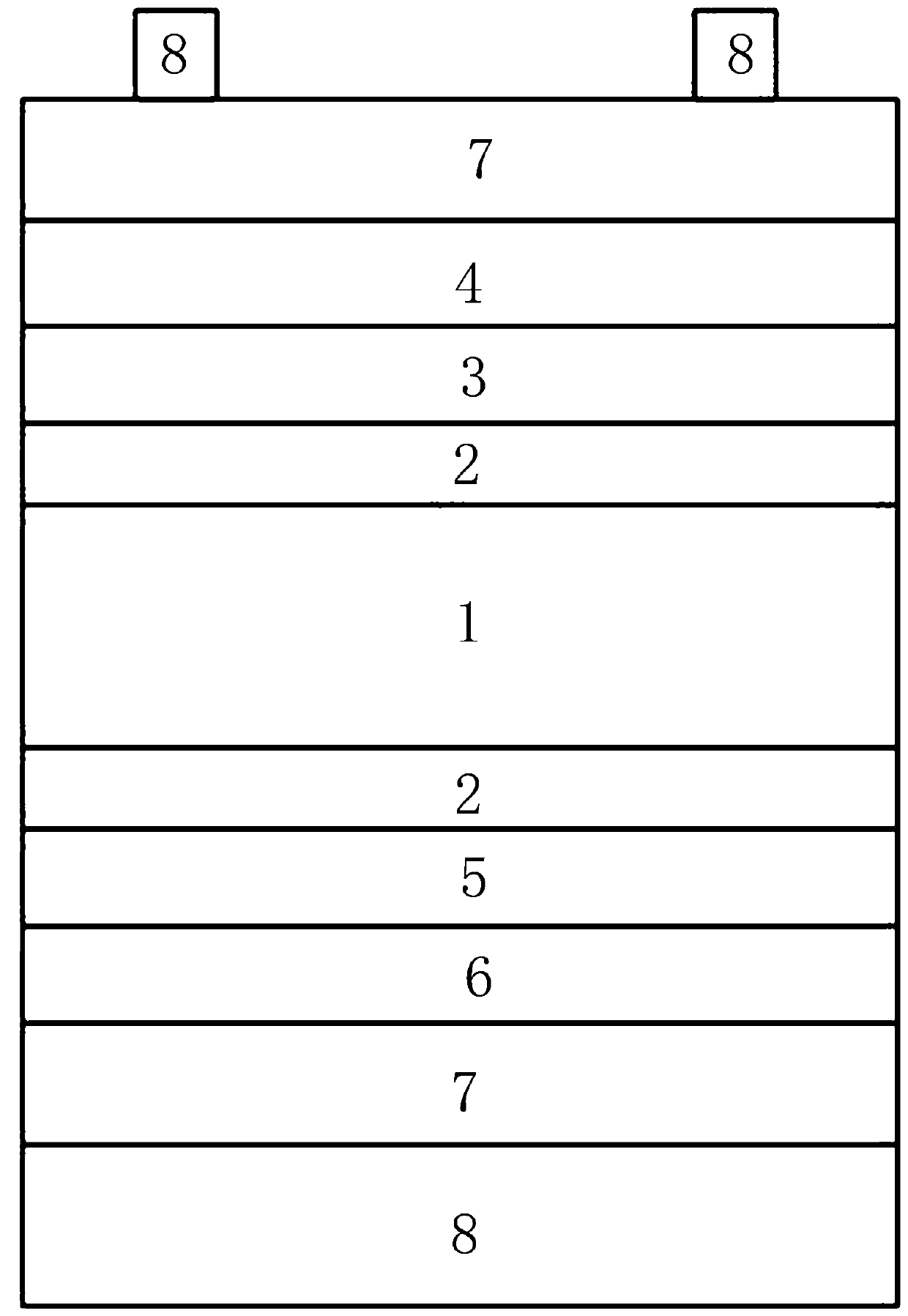

[0017] See attached picture. The solar cell described in this embodiment comprises a crystalline silicon layer 1 with an ultra-thin silicon oxide passivation layer 2 (1.4nm) on both sides, and a hydrogenated microcrystalline silicon oxide layer 3 (15nm) is grown sequentially on the front side of the silicon wafer , hydrogenated nanocrystalline silicon layer 4 (15nm), the two form a mixed-phase silicon oxide / nanocrystalline silicon layer; the reverse side also has intrinsic hydrogenated amorphous silicon layer 5 (10nm), p-type hydrogenated amorphous silicon layer 6 (10nm) , there are ITO layers 7 and Ag electrodes 8 on both sides.

[0018] When preparing:

[0019] 1. Silicon wafer cleaning and surface ultra-thin silicon oxide passivation layer growth

[0020] First, clean the silicon wafer and passivate the ultra-thin oxide layer, which can reduce the impurity concentration on the surface of the silicon wafer and reduce the interface defect state density between the silicon w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com