Light diffusion plate, optical unit and liquid crystal display

A light-diffusing, liquid crystal polymer technology, applied in the field of light-diffusing plates, can solve problems such as difficult operation, difficult production, and lack of collimation, so as to reduce absorption loss, improve brightness, and highlight brightness and clarity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

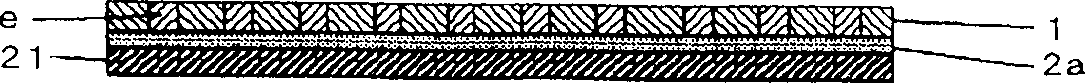

Embodiment 1

[0075] 100 parts of a 25% by weight toluene solution containing a norbornene series resin having hydrocarbons (trade name Zeonex, produced by Nihon Zeon Co., Ltd.) as a birefringent stretched film raw polymer and 6 parts by the following [molecular formula 5] (where n=35, which is the molecular weight % of the monomer unit, expressed as a block for convenience. Average molecular weight: 10000) The side chain type liquid crystal polymers represented were mixed together. By the casting method, the mixture was cast to form a thin film with a thickness of 100 μm. The formed film was stretched at 160° C. at a three-fold stretching ratio to obtain a light-diffusing plate comprising a birefringent stretched film comprising microparticles of the above-mentioned side chain type liquid crystal polymer in a dispersed state. Domain.

[0076] In the birefringent stretched film described above, the norbornene series resin forms a film in which the side chain type liquid crystal polymer i...

Embodiment 2

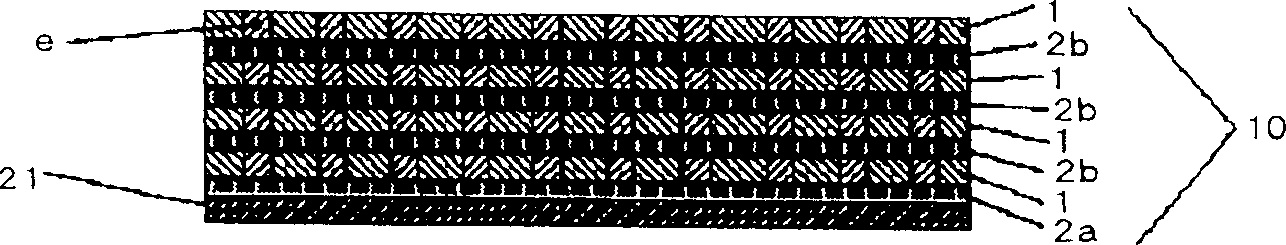

[0083] The light-diffusing plate obtained in Example 1, and a commercially available polarizing plate having a total light transmittance of 41% and a degree of polarization of transmitted light of 99% are adhered together by an acrylic resin series adhesive layer so that the The orientation of the extension axis and the transmission axis can be aligned and an optical element can be produced.

Embodiment 3

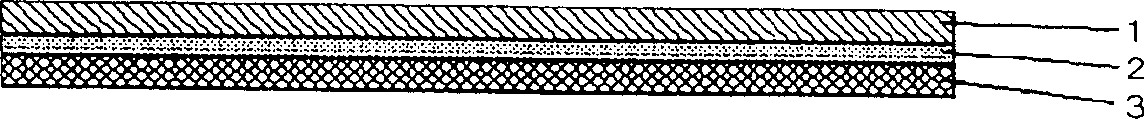

[0085] The polarizing plate, the TN liquid crystal cell, and the optical element obtained in Example 3 were bonded one by one on the diffuse reflection plate through an acrylic resin series adhesive layer, so that the polarizing plate can be formed on the side of the cell to obtain such Figure 4 The reflective LCD shown in. In addition, the polarizing plate is arranged so that the direction of the transmission axis can be consistent with each rubbing direction satisfying the requirements of the liquid crystal cell.

[0086] The luminance of the liquid crystal display obtained in Example 3 in the display state was measured with a luminance meter, and it was confirmed that the luminance was greatly improved compared with the case of using only the polarizing plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com