Microstructured hollow-core optical fiber

A technology of hollow-core fiber and microstructure, applied in the direction of microstructure fiber, cladding fiber, light guide, etc., can solve the problems that affect the low-loss bandwidth and loss of the fiber, and cannot reduce the limit loss of the fiber, so as to increase the damage threshold and reduce material absorption. Loss, reduce the effect of limiting loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

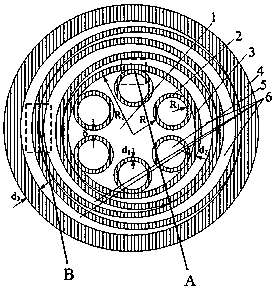

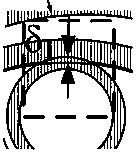

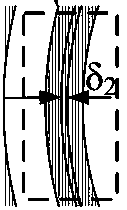

[0028] The invention provides a microstructure hollow fiber, such as figure 1 , figure 2 and image 3 As shown, the optical fiber includes a first-type medium tube 2, a second-type medium tube 3 and a third-type medium tube 4, and the first-type medium tube 2 is nested in the second-type medium tube The inside of the tube 3 is arranged periodically along the circumferential line, the minimum distance δ between the outer walls of two adjacent first-type medium tubes 2 > 0, and the second-type medium tube 3 is nested in the third-type medium tube 4. Inside; the first type of medium tube 2 and the second type of medium tube 3 are connected in a tangential manner, the thickness δ of the intersection of the first type of medium tube 2 and the second type of medium tube 3 1 =0, two adjacent second-type medium tubes 3 are connected in a tangential manner, and the intersecting thickness δ between adjacent second-type medium tubes 3 2 =0, the second-type medium pipe 3 and the third...

Embodiment 2

[0032] The present invention provides a microstructured hollow fiber. The optical fiber includes a first-type medium tube 2, a second-type medium tube 3 and a third-type medium tube 4. The first-type medium tube 2 is nested Inside the second-type medium tubes 3 and arranged periodically along the circumference, the minimum distance between the outer walls of two adjacent first-type medium tubes 2 is greater than 0, and the second-type medium tubes 3 are nested in The inside of the third type of medium tube 4; the first type of medium tube 2 and the second type of medium tube 3 are connected in an intersecting manner, the first type of medium tube 2 and the second type of medium Thickness δ of circular tube 3 intersecting 1 >0, two adjacent second-type medium circular tubes 3 are connected by intersection, the thickness δ of the intersection between adjacent second-type medium circular tubes 3 2 >0, the round pipe 3 of the second type of medium and the round pipe 4 of the thir...

Embodiment 3

[0035] The present invention provides a microstructured hollow fiber. The optical fiber includes a first-type medium tube 2, a second-type medium tube 3 and a third-type medium tube 4. The first-type medium tube 2 is nested Inside the second-type medium tubes 3 and arranged periodically along the circumference, the minimum distance between the outer walls of two adjacent first-type medium tubes 2 is greater than 0, and the second-type medium tubes 3 are nested in The inside of the third type of medium tube 4; the first type of medium tube 2 and the second type of medium tube 3 are connected in a tangential manner, the first type of medium tube 2 and the second type of medium tube The intersecting thickness δ of medium pipe 3 1 =0, two adjacent second-type medium tubes 3 are connected by intersection, the thickness δ of the intersection between adjacent second-type medium tubes 3 2 >0, the second-type medium pipe 3 and the third-type medium pipe 4 are connected in a tangential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com