Trapezoid metal dielectric film broadband pulse compressed grating

A metal medium, broadband pulse technology, applied in the direction of diffraction grating and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

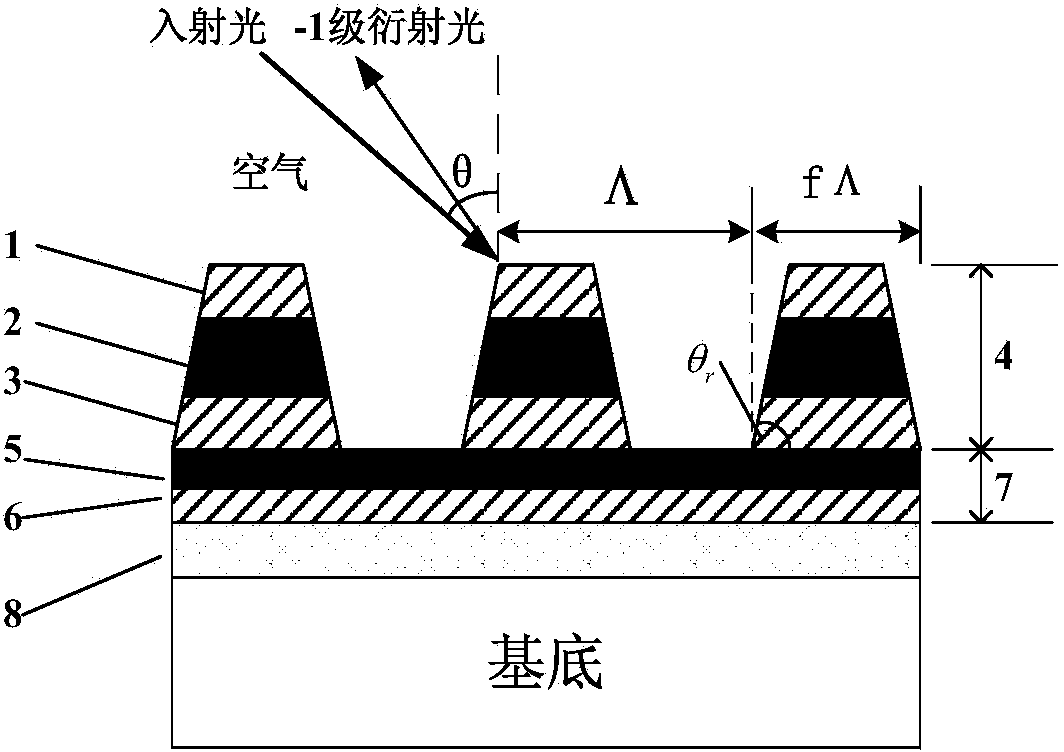

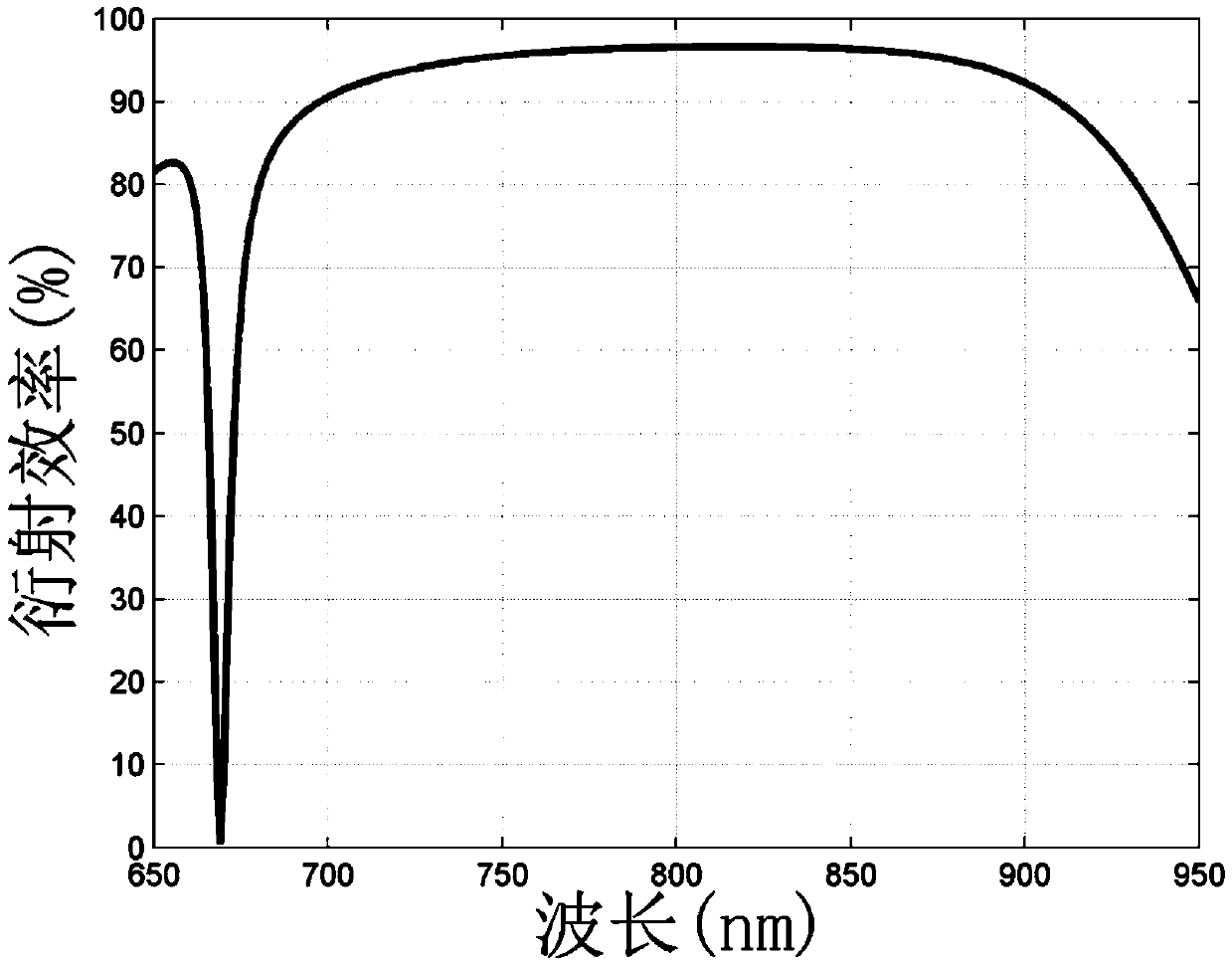

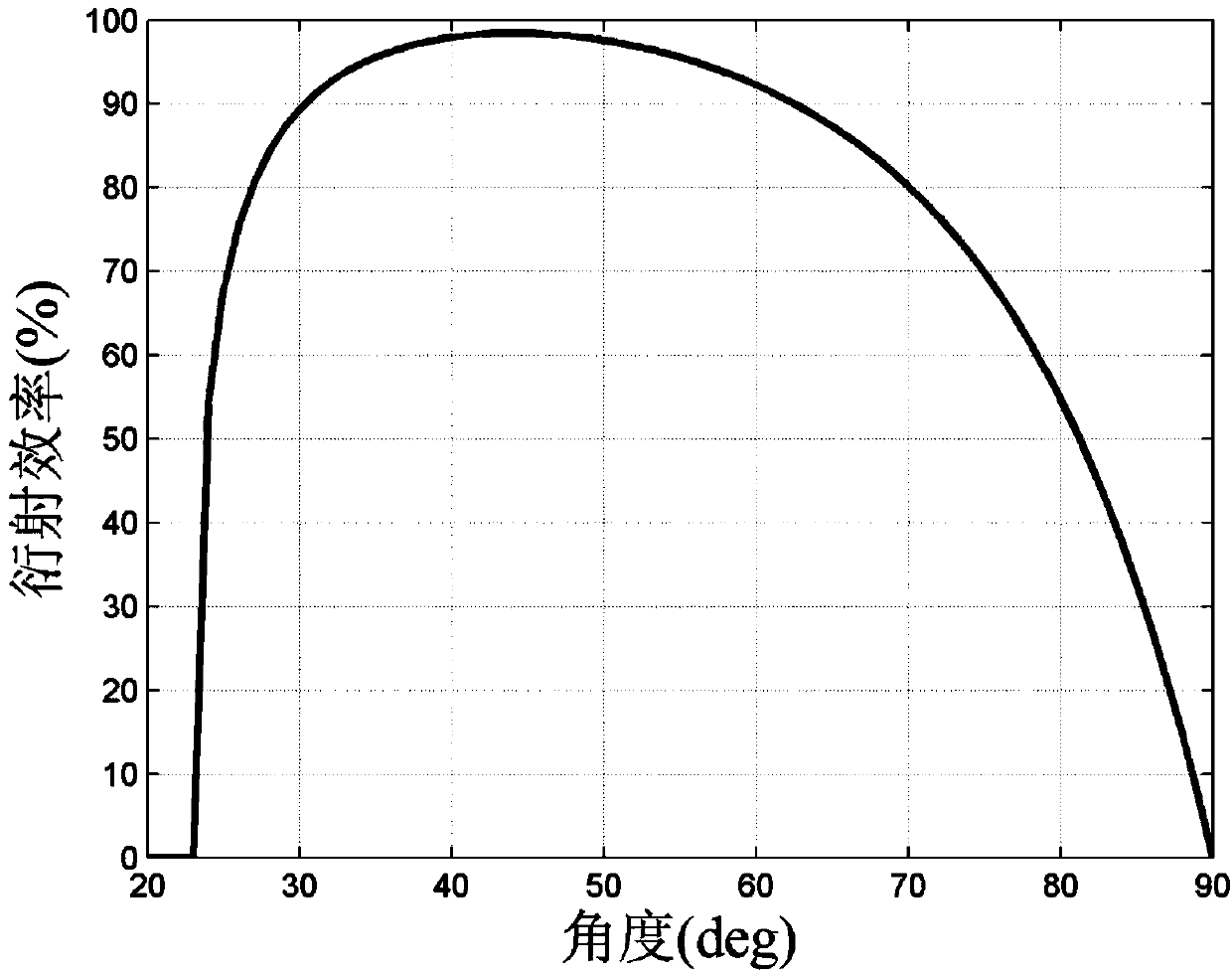

[0028] A trapezoidal metal dielectric film broadband pulse compression grating for a central wavelength of 800 nanometers is composed of a quartz substrate, a metal layer 8, a matching layer 7 composed of two dielectric films, and a trapezoidal grating ridge 4. The trapezoidal grating 4 has a period of 574.7 nanometers, a duty ratio of 0.43, a grating ridge base angle of 75°, and an outer layer of 1SiO 2 (refractive index 1.45) thickness 100 nm, interlayer 2HfO 2 (refractive index 1.96) layer thickness 149 nm, inner layer 3SiO 2 Thickness 57 nm. The outer layer 5 of the matching layer 7 is HfO 2 , with a thickness of 119 nm; the inner layer 6 is SiO 2 , with a thickness of 81 nm. The gold layer 8 has a thickness of 200 nm. Such as figure 2 , when the incident angle is 53°, for the incident light of 800 nm, the -1 order diffraction efficiency of the grating TE is the highest, greater than 97%, and in the wavelength range of 700-900 nm, the -1 order diffraction efficiency...

Embodiment 2

[0030] A trapezoidal metal dielectric film broadband pulse compression grating for a central wavelength of 800 nanometers is composed of a quartz substrate, a metal layer 8, a matching layer 7 composed of two dielectric films, and a trapezoidal grating ridge 4. The period of the trapezoidal grating 4 is 555 nanometers, the duty ratio is 0.27, the bottom angle of the grating ridge is 89°, and the outer layer 1 is SiO 2 (refractive index 1.45) thickness 110 nm, middle layer 2 is TiO 2 (refractive index 2.12) layer thickness 150nm, inner layer 3 is SiO 2 Thickness 60 nm. The outer layer 5 of the matching layer 7 is TiO 2 , with a thickness of 120 nm; the inner layer 6 is SiO 2 , with a thickness of 80 nm. The gold layer 8 has a thickness of 150 nm. Such as Image 6When the incident angle is 53°, for the incident light at 800 nm, the -1 order diffraction efficiency of the grating TE is the highest, greater than 97%, and in the wavelength range of 700-952 nm, the -1 order dif...

Embodiment 3

[0032] A trapezoidal metal dielectric film broadband pulse compression grating for a central wavelength of 800 nanometers is composed of a quartz substrate, a metal layer 8, a matching layer 7 composed of two dielectric films, and a trapezoidal grating ridge 4. The period of the trapezoidal grating 4 is 555 nanometers, the duty ratio is 0.62, the bottom angle of the grating ridge is 60°, and the outer layer 1 is SiO 2 (refractive index 1.45) thickness 50 nm, middle layer 2 is TiO 2 (refractive index 2.12) layer thickness 150nm, inner layer 3 is SiO 2 Thickness 60 nm. The outer layer (5) of the matching layer 7 is TiO 2 , with a thickness of 120 nm; the inner layer 6 is SiO 2 , with a thickness of 80 nm. The gold layer 8 has a thickness of 100 nm. Such as Figure 8 When the incident angle is 53°, for the incident light at 800 nm, the -1 order diffraction efficiency of the grating TE is the highest, greater than 97%, and in the wavelength range of 700-920 nm, the -1 order ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com