Thin-film photovoltaic cell and manufacturing method thereof

A thin-film photovoltaic cell and manufacturing method technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as low effective light utilization rate, thick absorption layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

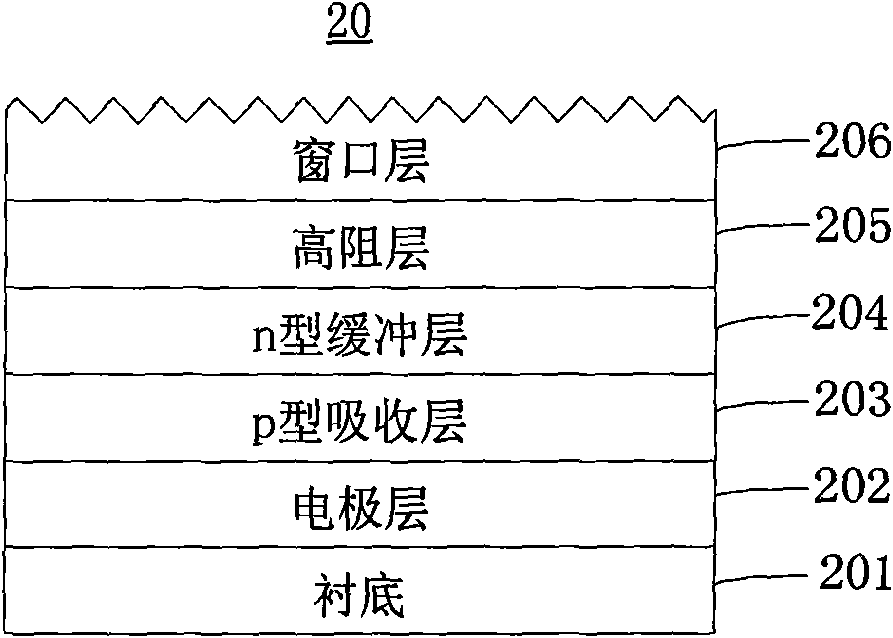

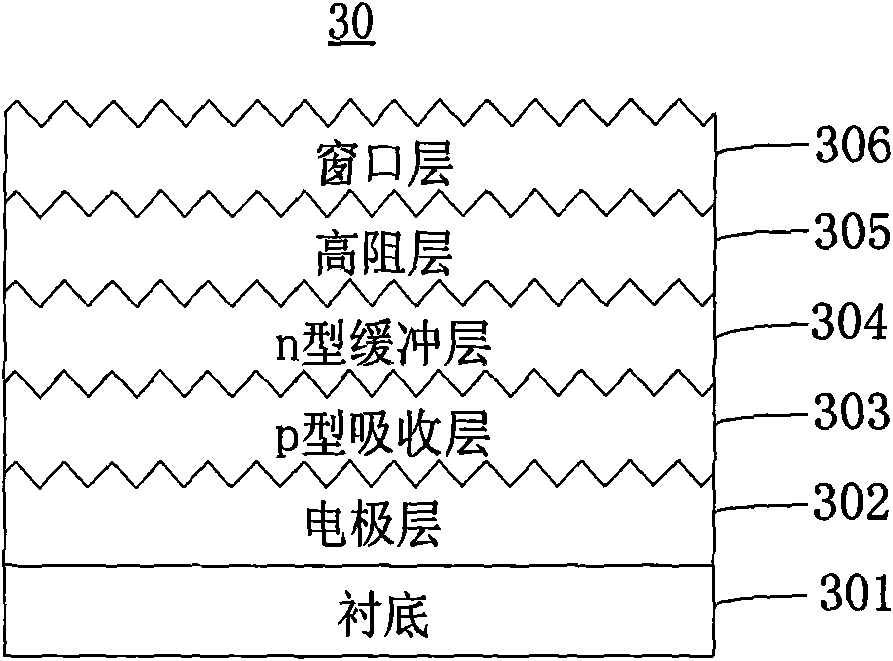

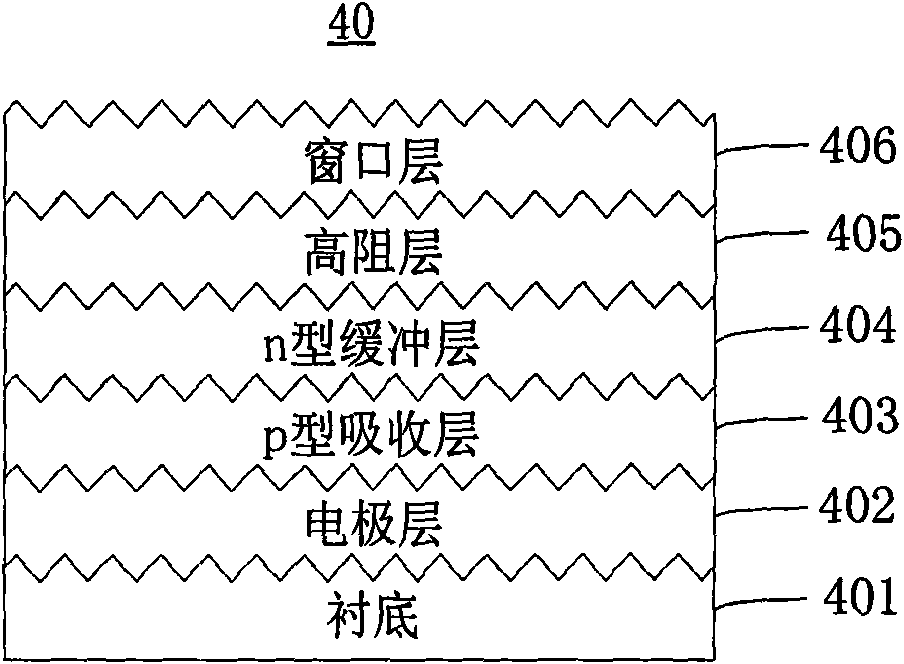

[0025] figure 1 is a schematic diagram of the first embodiment of a CIGS / CIS thin film photovoltaic cell. From bottom to top are substrate 201 , electrode layer 202 , p-type absorber layer 203 , n-type buffer layer 204 , high resistance layer 205 and window layer 206 . The substrate 201 can be a soda-lime glass substrate, the electrode layer 202 can be a molybdenum electrode layer, the material of the p-type absorption layer 203 is CIGS / CIS, the material of the n-type buffer layer 204 is CdS, and the material of the high resistance layer 205 is ZnO , the window layer 206 is a ZnO-based transparent conductive window layer with low absorption and high conductance in the near-infrared band, and the window layer 206 adopts a light-trapping structure.

[0026] The light-trapping structure refers to the uneven shape of the surface. Specifically, it can be in the shape of ripples, V-shaped grooves, random or uniformly distributed pyramid shapes, and the like. The light-trapping st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com