Efficient polarization purifying device

A purification device and high-efficiency technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of low transmitted light energy and high cost, and achieve the effects of high polarization degree, energy enhancement, and high polarization purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

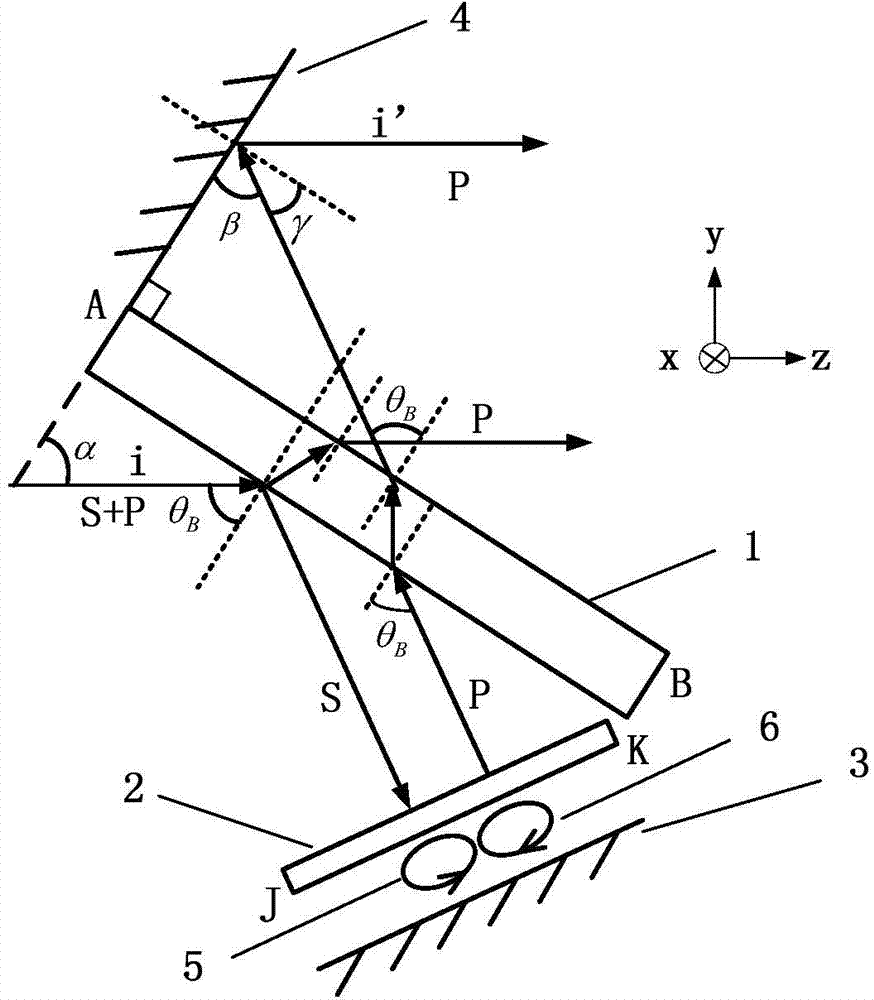

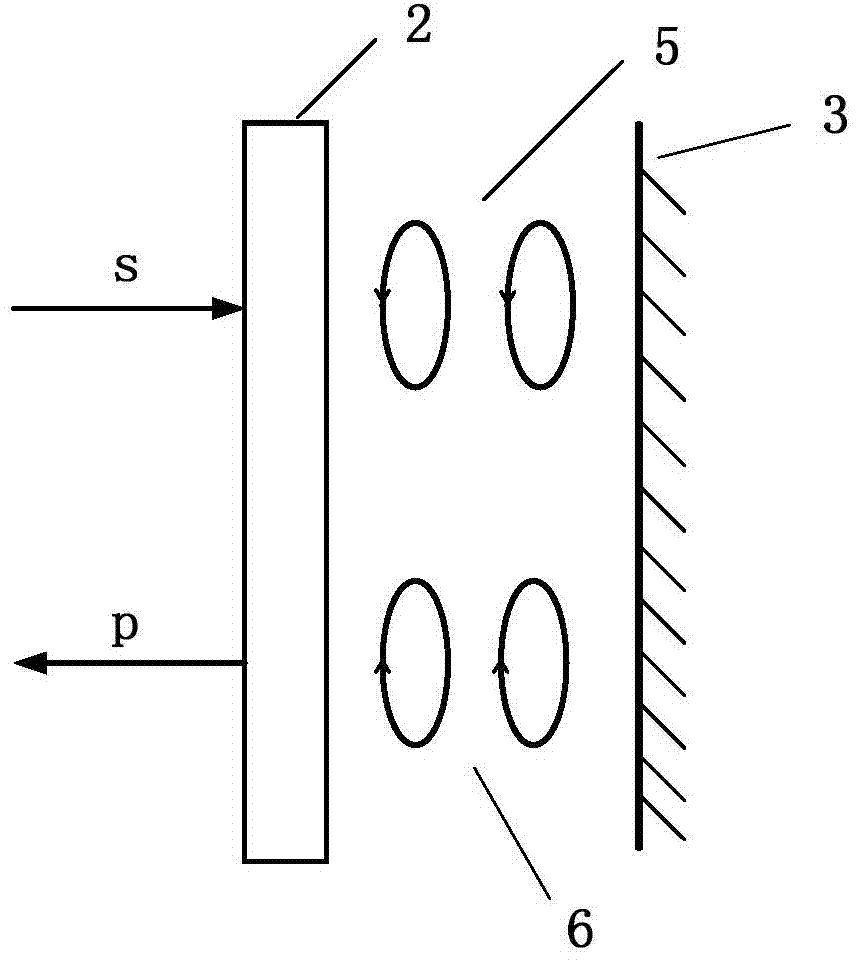

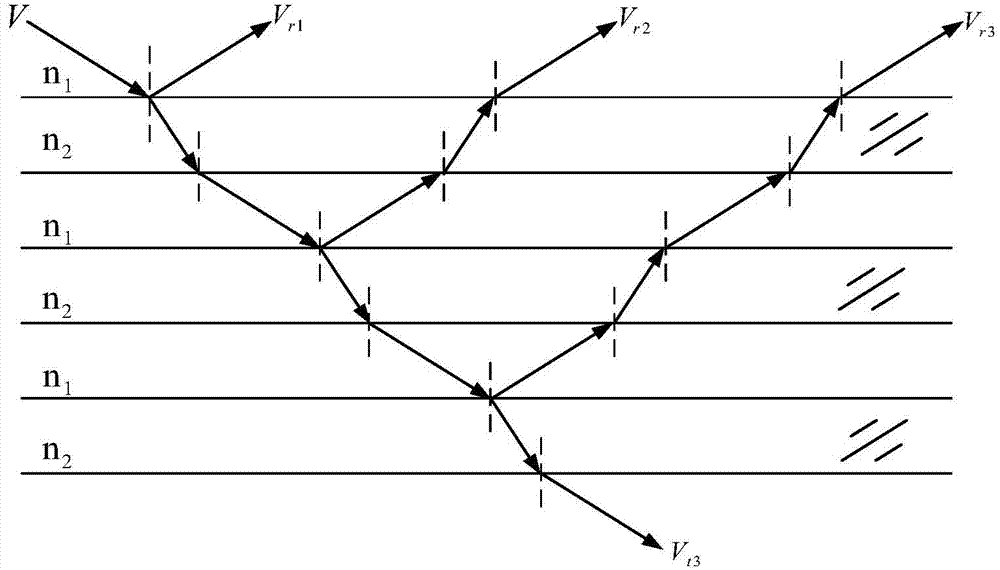

[0021] figure 1 It is the main structure diagram of the high-efficiency polarization purification device. It consists of a wave plate stack 1, a quarter wave plate 2, a first mirror 3 and a second mirror 4. In the figure θ B Represents Brewster's angle, and different materials have different Brewster's angles. In this embodiment, for the 193nm band, the wave plate stack 1 uses fused silica as a material with a good transmittance to ultraviolet light, and the refractive index is 1.560321, so the Brewster angle is 57.344°. The surface normal of the wave plate stack 1 is The horizontal direction is 57.344°. For CaF 2 , MgF 2 , K9 and other UV-permeable materials or corresponding materials in other wave bands (such as ordinary quartz glass in the visible light band), the principle of this device is also applicable. Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com