Uniaxially stretched multi-layer laminate film, polarizing plate comprising same, optical member for liquid crystal display device, and liquid crystal display device

一种液晶显示装置、单轴拉伸的技术,应用在光学元件、偏振元件、光学等方向,能够解决反射偏振器与吸收元件粘接力降低等问题,达到优异耐久性、对比度高、高耐久性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

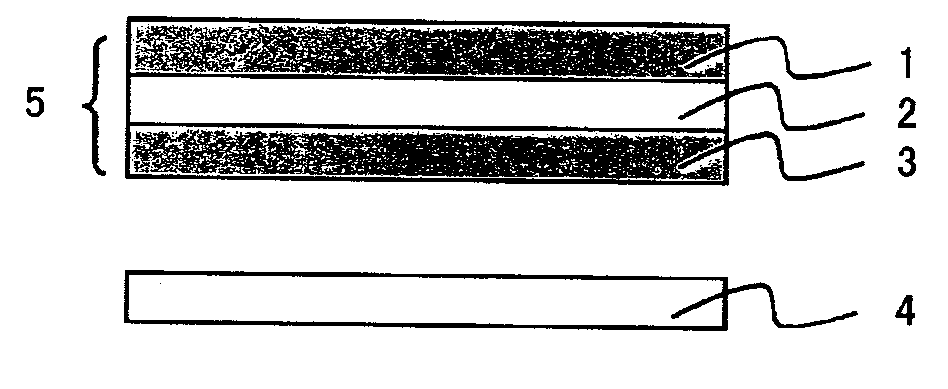

preparation example Construction

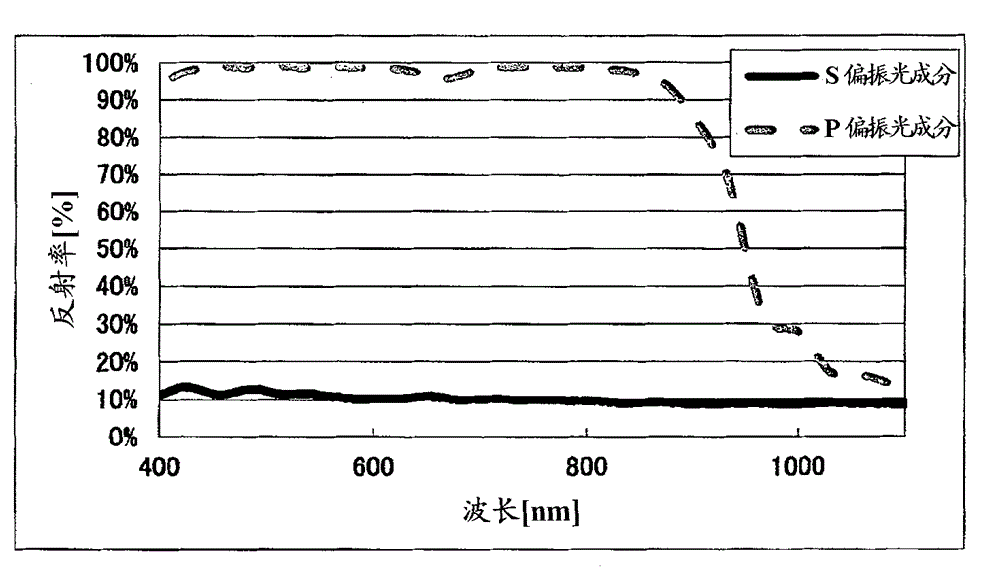

[0147] Due to the relationship between the preparation method of the above-mentioned intermediate layer, the outermost layer of the uniaxially stretched multilayer laminated film becomes the buffer layer, and the multiple reflection absorption effect produced by the intermediate layer is passed through the intermediate layer arranged inside the multilayer structure. Contains visible light absorbers for effect. That is, even if only the visible light absorber is contained in the outermost layer of the multilayer structure, the transmittance of P-polarized light and the transmittance of S-polarized light decrease in the same ratio, so the value of the degree of polarization (P) does not change. Therefore, in the production of a multilayer laminated film, a layer of the same composition can be arranged in the outermost layer of the multilayer structure together with the intermediate layer of the present invention, but in this case, the degree of polarization will not be further in...

Embodiment 1

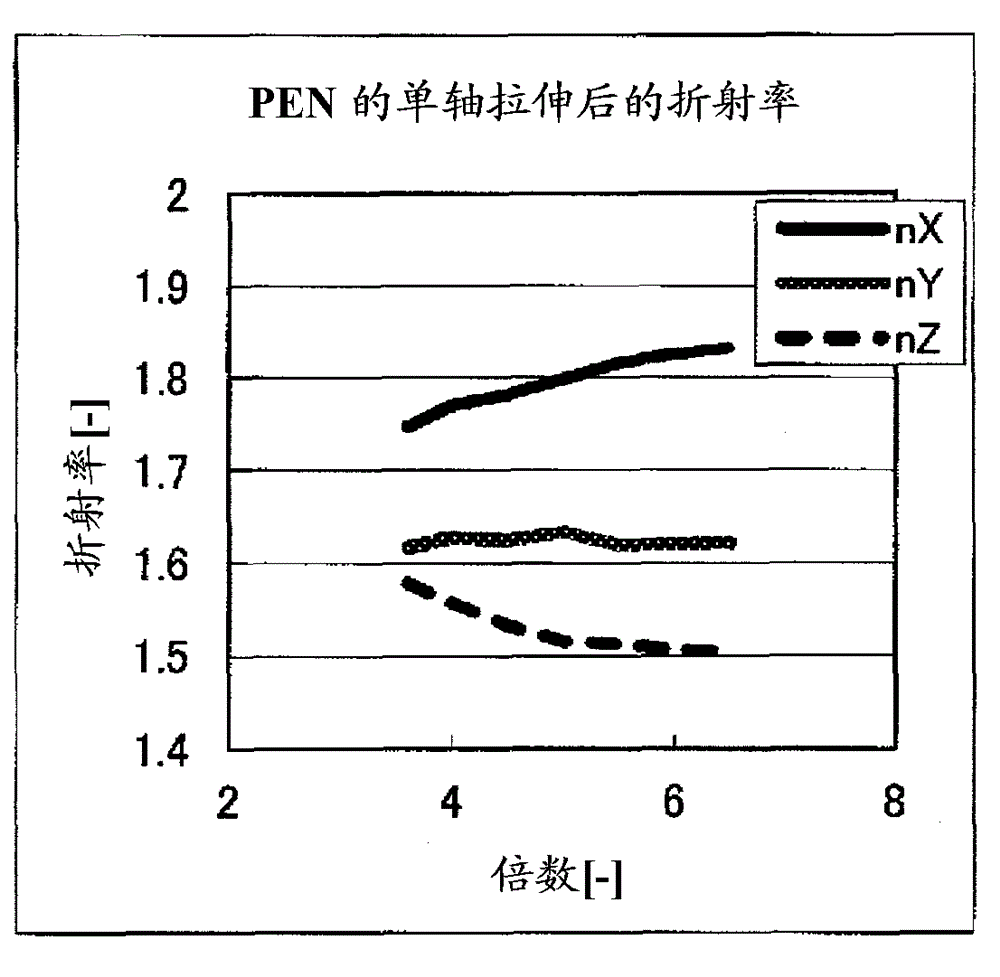

[0339] Esterification and transesterification of dimethyl 2,6-naphthalene dicarboxylate, 6,6'-(ethylenedioxy)di-2-naphthoic acid and ethylene glycol in the presence of titanium tetrabutoxide reaction, and then continue to carry out the polycondensation reaction, the intrinsic viscosity is 0.62dl / g and 65 mol% of the acid component is 2,6-naphthalene dicarboxylic acid component (represented as PEN in the table), and 35 mol% of the acid component is 6,6 '-(Ethylenedioxy)di-2-naphthoic acid component (represented as ENA in the table) and an aromatic polyester whose diol component is ethylene glycol were used as the polyester for the first layer, and an intrinsic viscosity (o- A polyethylene terephthalate (IA20PET) in which 20 mol% of isophthalic acid was copolymerized with 0.62 dl / g of chlorophenol, 35° C. was used as the polyester for the second layer.

[0340] To the prepared polyester for the first layer, 0.12% by weight (1200 ppm) of carbon black (manufactured by EVONIK INDUS...

Embodiment 2~12

[0351] As shown in Table 1, except that the resin composition of each layer, the type of visible light absorber and ultraviolet absorber, the amount added, the thickness of the layer, the number of multiplications, and the preparation conditions were changed, the uniaxial tensile strength was obtained in the same manner as in Example 1. A multi-layer laminated film is stretched, and this film is used as a first polarizing plate to form a liquid crystal panel to prepare a liquid crystal display.

[0352] It should be noted that the NDC20PET used as the polyester for the second layer in Example 2 is polyethylene terephthalate obtained by copolymerizing 20 mol% of isophthalic acid used as the polyester for the second layer in Example 1. The copolymerization component of the glycol ester (IA20PET) was changed to a copolyester of 2,6-naphthalene dicarboxylic acid. Similarly, the polyester for the second layer in Example 3 was 2,6-naphthalene dicarboxylic acid whose copolymerization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com