Patterned sapphire substrate with nonpolar and semipolar surface, visual light communication light source with nonpolar and semipolar surface and preparation method thereof

A sapphire substrate and visible light communication technology, applied in the field of visible light communication, can solve the problems of restricted modulation bandwidth, high background carrier concentration, insufficient light absorption, and slow response speed, so as to increase the proportion and rate of radiative recombination and improve the visible light Communication performance, the effect of reducing the formation of polycrystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The preparation method of the visible light communication light source with non-polar and semi-polar surfaces comprises the steps of:

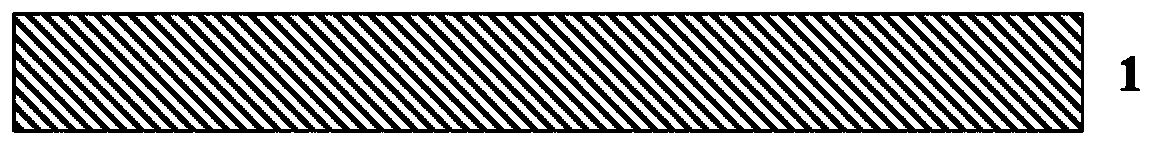

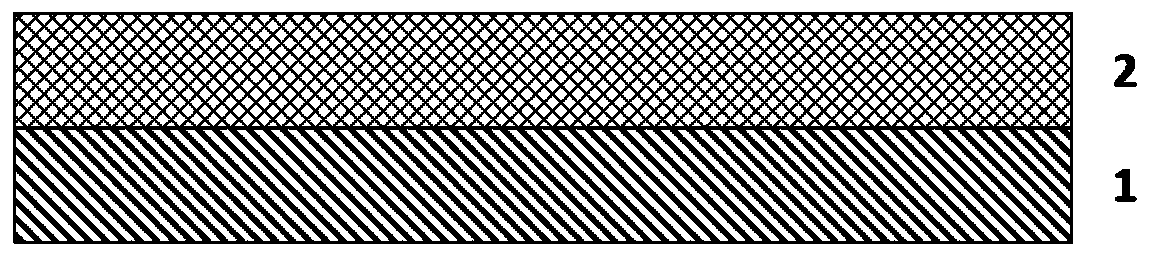

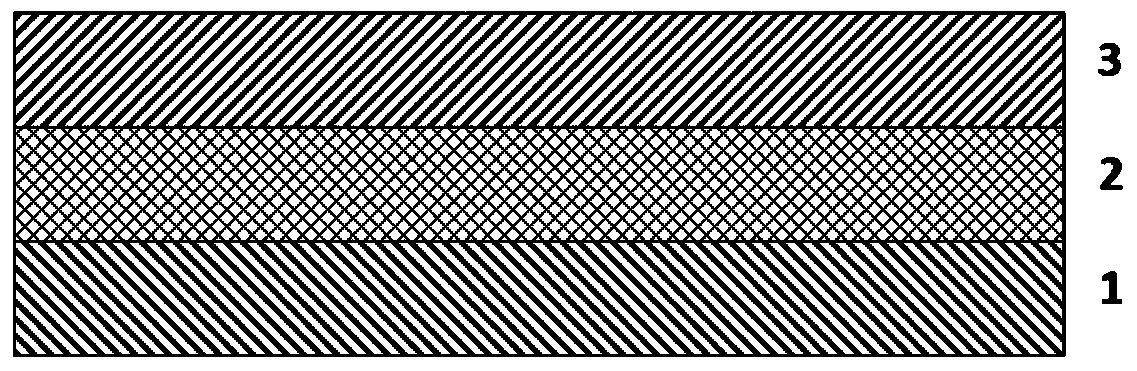

[0055] (1) A 2-inch r-plane sapphire substrate 1 is selected. The basic performance parameters of the r-plane sapphire substrate are as follows: the average half-peak width is 19.4arcsec; the dislocation density is 5.6×10 3 cm -3 ; The average transmittance when the wavelength is greater than 300nm is greater than 80%; Optical uniformity Δn = 6.6 × 10 -5 ; The average surface roughness is 0.49nm.

[0056] (2) Using PECVD technology to grow a SiO on a sapphire substrate 2 The dielectric layer 2 has a thickness of 200nm.

[0057] (3) Spin-coat the photoresist 3 on the above-mentioned substrate. The photoresist is reversed glue AZ5214, the spin-coating speed is 600rpm / 8000rpm, the time is 10s / 40s, and the pre-baking is performed on a hot plate at 90°C for 1 minute. Due to the use of reverse glue, a two-step exposure method is used. Fir...

Embodiment 2

[0070] The preparation method of the visible light communication light source with non-polar and semi-polar surfaces comprises the steps of:

[0071] (1) A 2-inch r-plane sapphire substrate 1 is selected. The basic performance parameters of the r-plane sapphire substrate are as follows: the average half-peak width is 19.4arcsec; the dislocation density is 5.6×10 3 cm -3 ; The average transmittance when the wavelength is greater than 300nm is greater than 80%; Optical uniformity Δn = 6.6 × 10 -5 ; The average surface roughness is 0.49nm.

[0072] (2) Using PECVD technology to grow a SiO on a sapphire substrate 2 The dielectric layer 2 has a thickness of 200nm.

[0073] (3) Spin-coat the photoresist 3 on the above-mentioned substrate. The photoresist is reversed glue AZ5214, the spin-coating speed is 600rpm / 8000rpm, the time is 10s / 40s, and the pre-baking is performed on a hot plate at 90°C for 1 minute. Due to the use of reverse glue, a two-step exposure method is used. Fir...

Embodiment 3

[0085] The preparation method of the visible light communication light source with non-polar and semi-polar surfaces comprises the steps of:

[0086] (1) A 2-inch r-plane sapphire substrate 1 is selected. The basic performance parameters of the r-plane sapphire substrate are as follows: the average half-peak width is 19.4arcsec; the dislocation density is 5.6×10 3 cm -3 ; The average transmittance when the wavelength is greater than 300nm is greater than 80%; Optical uniformity Δn = 6.6 × 10 -5 ; The average surface roughness is 0.49nm.

[0087] (2) Using PECVD technology to grow a SiO on a sapphire substrate 2 The dielectric layer 2 has a thickness of 200nm.

[0088] (3) Spin-coat the photoresist 3 on the above-mentioned substrate. The photoresist is reversed glue AZ5214, the spin-coating speed is 600rpm / 8000rpm, the time is 10s / 40s, and the pre-baking is performed on a hot plate at 90°C for 1 minute. Due to the use of reverse glue, a two-step exposure method is used. Fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

| Cycle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com