White light LED area lighting source module package method

A technology of LED surface light source and packaging method, which is applied in the direction of planar light source, electroluminescent light source, light source, etc., can solve the problems of reduced glare point intensity, increased process difficulty, and complicated structural design, and achieves the reduction of heat dissipation requirements. Production technology, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

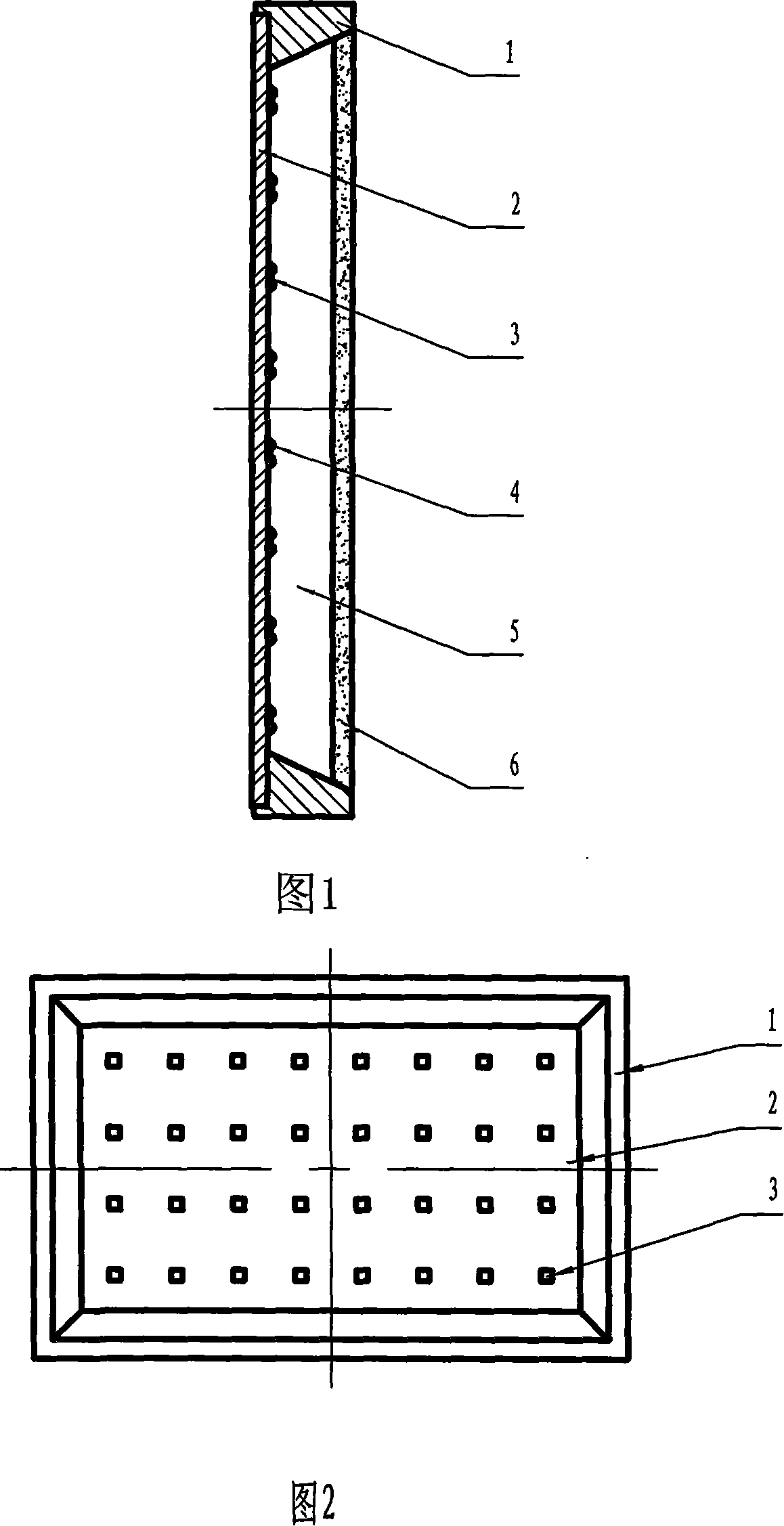

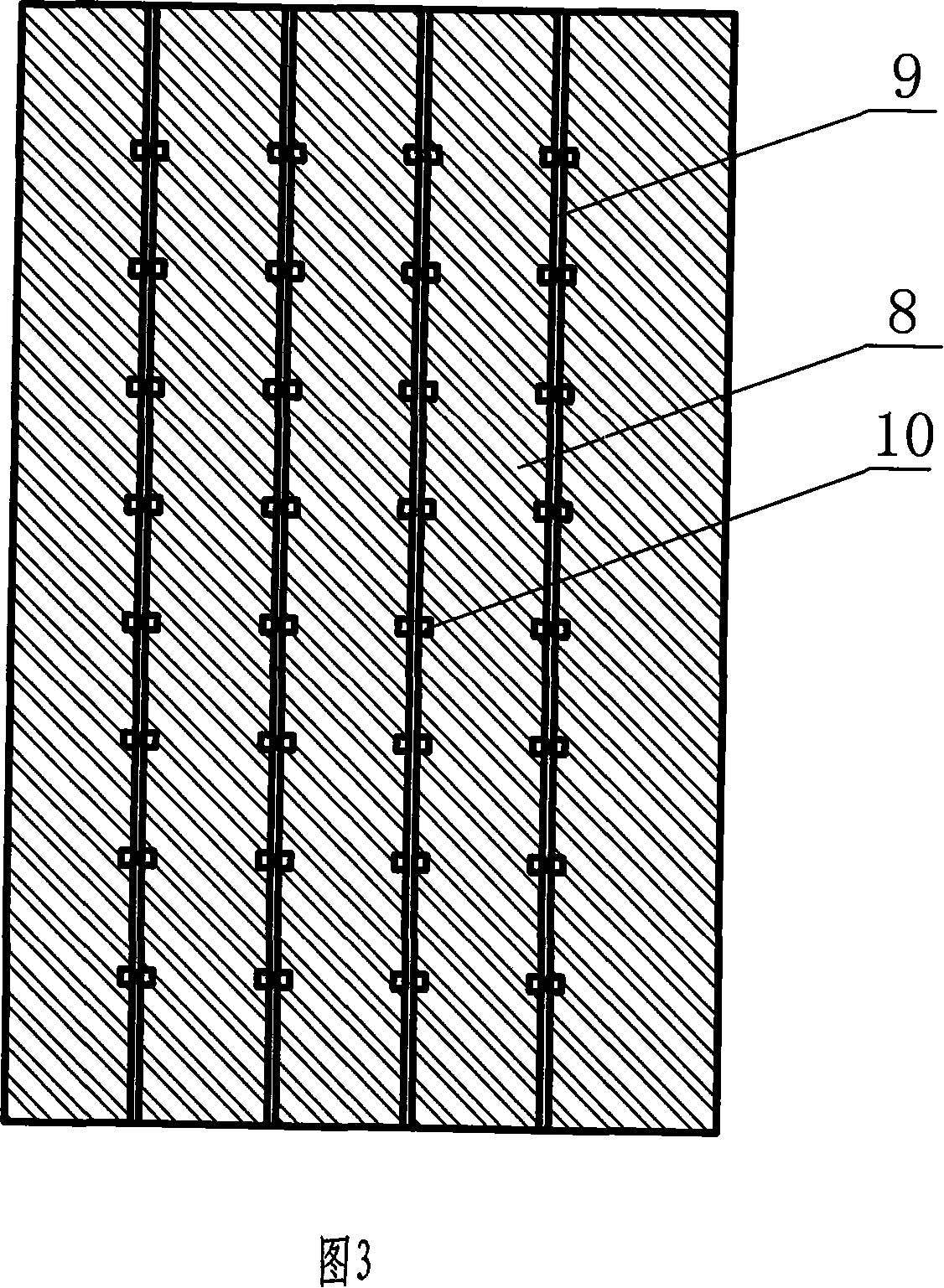

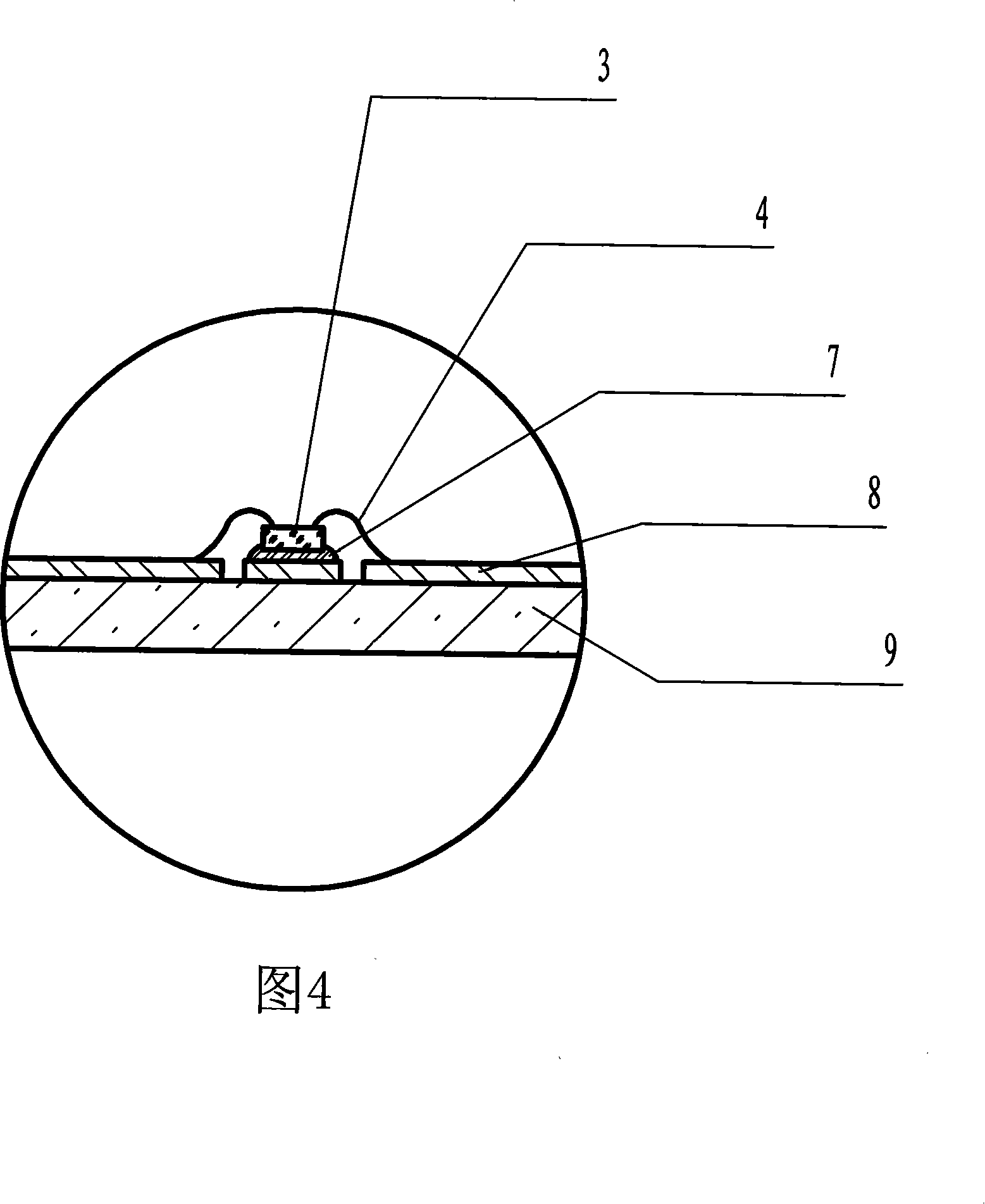

[0027] First select the chip and phosphor and design and make the circuit board. This embodiment uses a 460-465nm band blue light chip, the chip normal light intensity is 160-180mcd, the voltage range is 3.0-3.5V, the chip size is 14×14mil, and phosphor powder that can be excited by 460-465nm light is used, such as Taiwan Hongdae's TMT-00432-6065 phosphor. In this embodiment, the circuit board is designed and produced according to the requirements of power 1W and voltage 12V. As shown in Figure 3, a circuit structure with four groups connected in series and 8 chips connected in parallel in each group is adopted. In the figure, 8 is the copper clad layer of the circuit board, 9 is the substrate of the circuit board, and 10 is the pad. In this embodiment, the circuit board adopts a half-glass fiber copper-clad laminate, the pad 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com