Deep ultraviolet micro-LED with high electro-optical conversion rate and inverted structure and preparation method of deep ultraviolet micro-LED

An electro-optical conversion and deep ultraviolet technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of sudden drop in light extraction efficiency, difficulties in light extraction efficiency, and inability to achieve large-scale commercialization and practical application, and achieve improvement Light extraction efficiency and anti-static breakdown ability, reducing forward conduction voltage and reverse leakage current, and improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

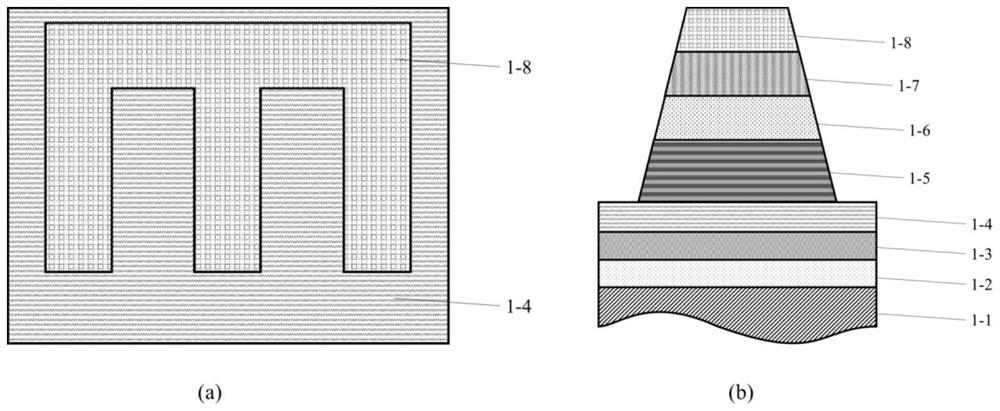

[0047] This embodiment is a method for preparing a chip unit with a 222 nm light emission wavelength in TM mode. The method for preparing a deep ultraviolet micro-LED with a high electrical-to-optical conversion rate flip-chip structure in this embodiment includes the following steps:

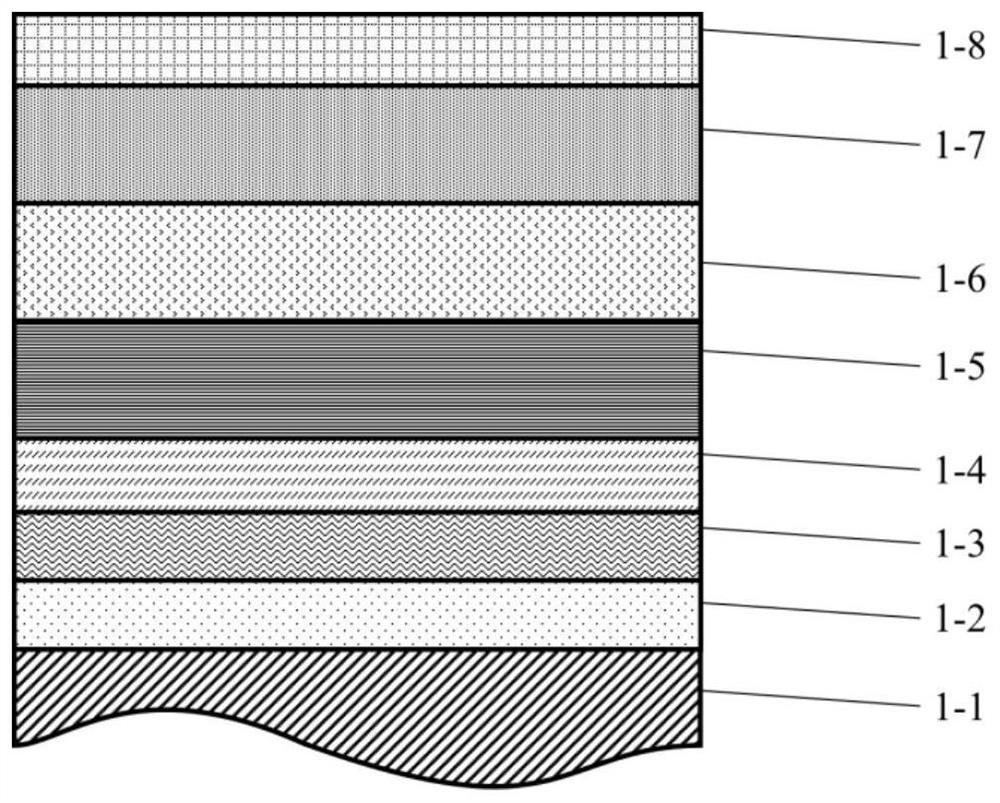

[0048] 1) Select a nitride semiconductor LED epitaxial wafer. From bottom to top, the semiconductor LED epitaxial wafer is the substrate 1-1 using sapphire, the nucleation layer 1-2 using AlN, the buffer layer 1-3 using AlGaN, and the N of AlGaN. Type doped layer 1-4, AlGaN / AlGaN multiple quantum well active region 1-5, electron blocking layer 1-6 and P-type doped layer composed of AlGaN 1-7 and GaN 1-8 The LED epitaxial wafer is pretreated to make the surface clean, such as figure 1 shown;

[0049] 2) According to the requirements of the prepared micro-LED, design an exposure layout with a size of 50 μm in length and 50 μm in width; spin-coat positive photoresist on the upper surface of the P...

Embodiment 2

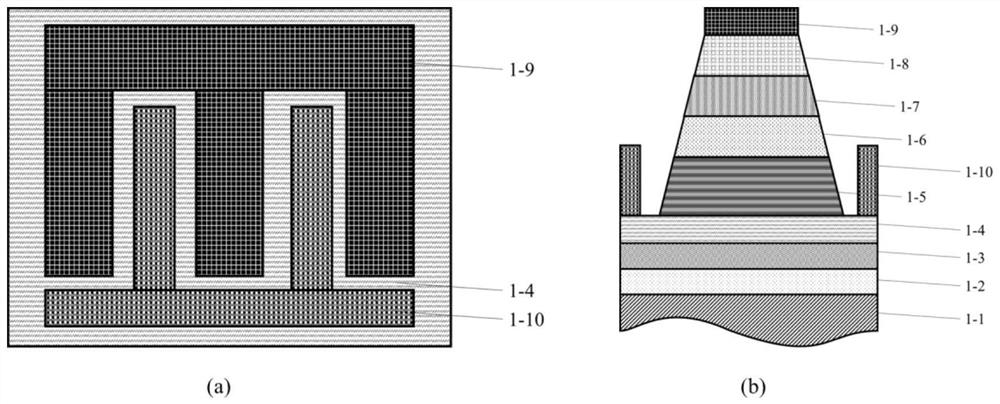

[0059] This embodiment is a method for preparing a plurality of chip units with an emission wavelength of 278 nm. The method for preparing a deep-UV micro-LED with a high electro-optical conversion rate flip-chip structure in this embodiment includes the following steps:

[0060] 1) Select a nitride semiconductor LED epitaxial wafer. From bottom to top, the semiconductor LED epitaxial wafer is the substrate 1-1 using sapphire, the nucleation layer 1-2 using AlN, the buffer layer 1-3 using AlGaN, and the N of AlGaN. Type doped layer 1-4, AlGaN / AlGaN multiple quantum well active region 1-5, electron blocking layer 1-6 and P-type doped layer composed of AlGaN 1-7 and GaN 1-8 The LED epitaxial wafer is pretreated to make the surface clean;

[0061] 2) According to the requirements of the prepared micro-LED, design the exposure layout, including a plurality of micro-mesa units, each of which is 25 μm long and 25 μm wide; spin-coat positive light on the upper surface of the P-type d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com