Metal metamaterial wave plate

A metamaterial and metal technology, applied in the field of metal metamaterial wave plates, can solve the problems of large structural aspect ratio, difficult preparation, and difficulty in popularization, and achieves the goal of reducing reflection and absorption loss, improving conversion efficiency, and improving integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

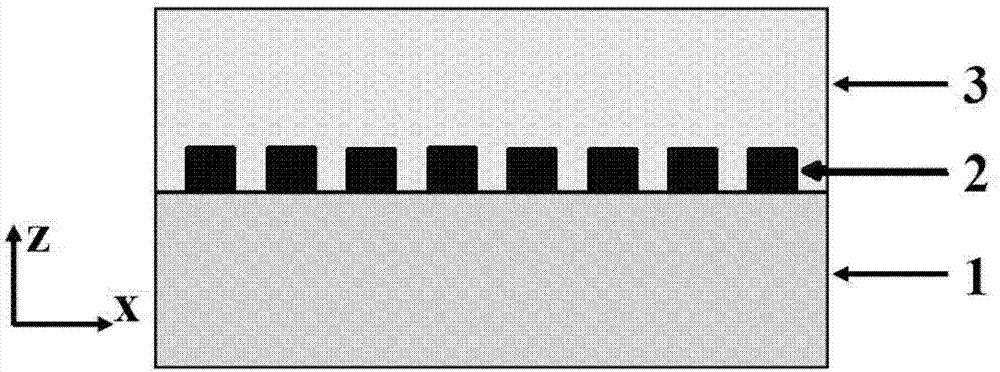

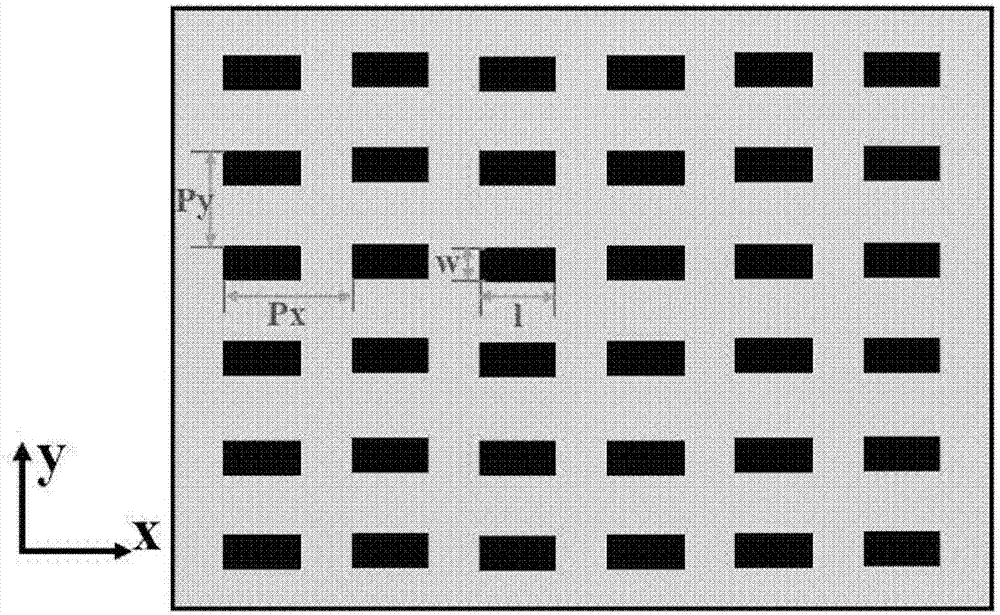

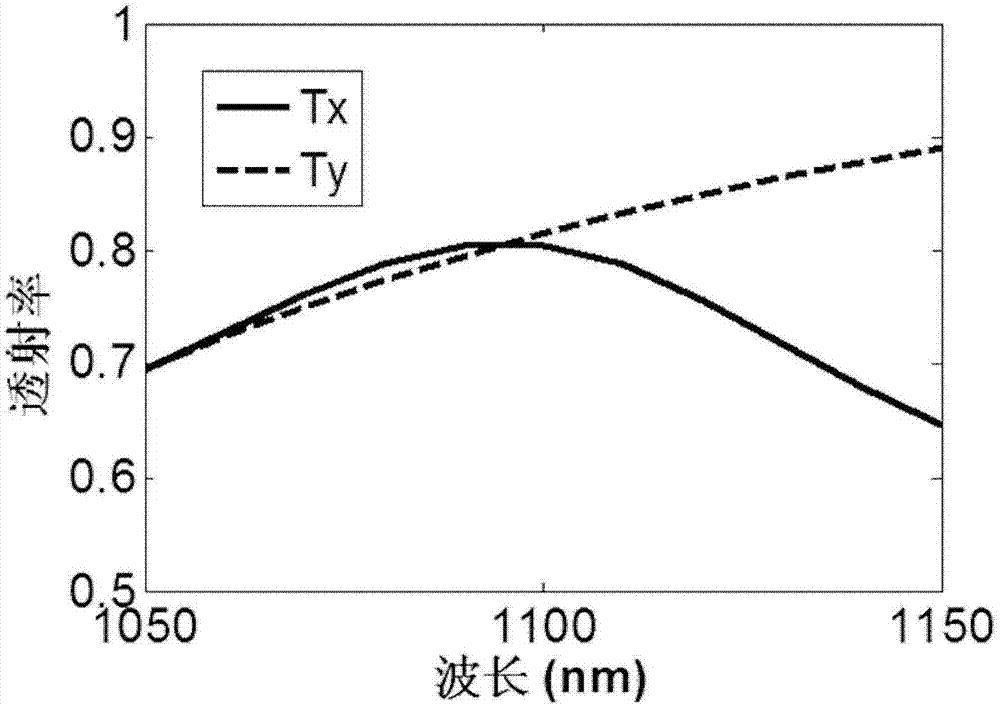

[0051] The metal metamaterial wave plate in this embodiment is a half-wave plate, which can rotate the polarization direction of incident light by 90 degrees, its working wavelength is 1.1 um, and its transmission efficiency is above 80%. The material of the dielectric substrate and the dielectric cladding layer of the half-wave plate is both quartz, and the material of the metal particles is silver. The size of the metal particle is: long axis length l=340nm, short axis length w=200nm, height h=360nm. The metal particle period along the x-axis direction is Px=600nm, and the period along the y-axis direction is Py=620nm.

[0052] The polarization direction of the incident light forms an angle of 45 degrees with the long axis and is perpendicular to the wave plate, so the intensity of the incident light component in the direction parallel to the long axis and the short axis is the same. image 3 is the variation curve of the transmittance of the incident light component polari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com