Manufacturing method of quartz optical fiber image bundle

A technology of quartz optical fiber and manufacturing method, which is applied to manufacturing tools, beam optical fibers, glass manufacturing equipment, etc., can solve the problem that multi-component glass optical fiber image transmission beams cannot meet the needs of long-distance image transmission, and achieve low absorption loss. , to ensure the effect of transmission quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Technical scheme of the present invention is as follows:

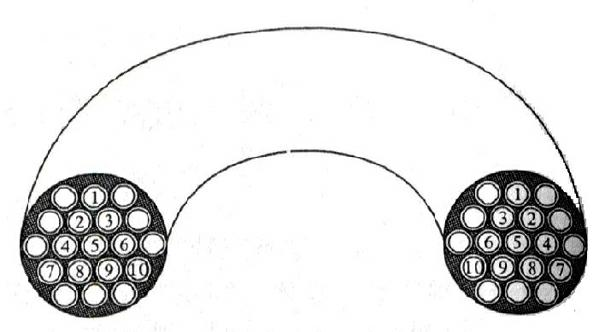

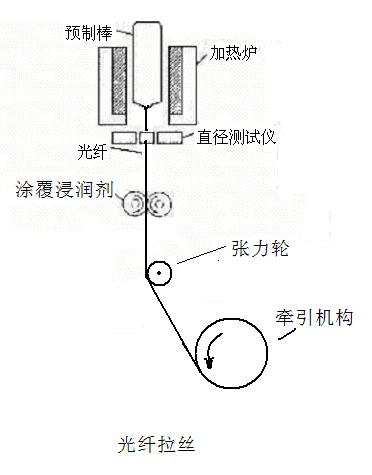

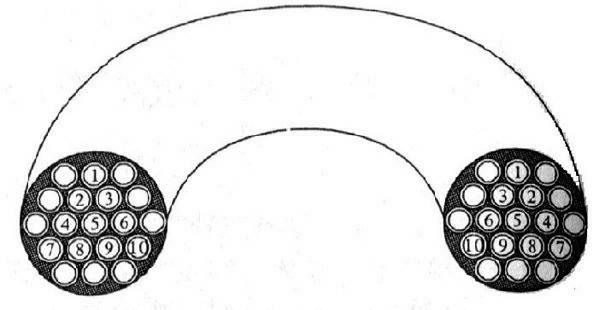

[0024] Firstly, the quartz preform with a core-skin structure is drawn into a silica fiber filament with a diameter of less than 50 μm through a high-temperature furnace. The diameter of the silica fiber filament directly affects the resolution of the image beam, that is, the image quality. In the drawing process, the sizing agent is applied to the fiber filaments after they come out of the high-temperature furnace. After the fiber filaments come out of the high-temperature furnace, they are coated before the upper winding mechanism, so as to ensure that the fibers have not been in contact with other mechanisms. That is to say, the sizing agent is applied to protect the optical fiber body when it has not been damaged by external damage, and then it is rewound to achieve the purpose of protecting the optical fiber filament; then the drawn filament is passed through the slide The wire arranging process is processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com