Cutting fluid for hard brittle material and uses thereof

A hard and brittle material, cutting fluid technology, applied in the field of chemical synthesis cutting fluid, can solve the problems of solid filler environmental pollution, oily cutting fluid is flammable, less use, etc., to achieve good chelating anti-settling function, low conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

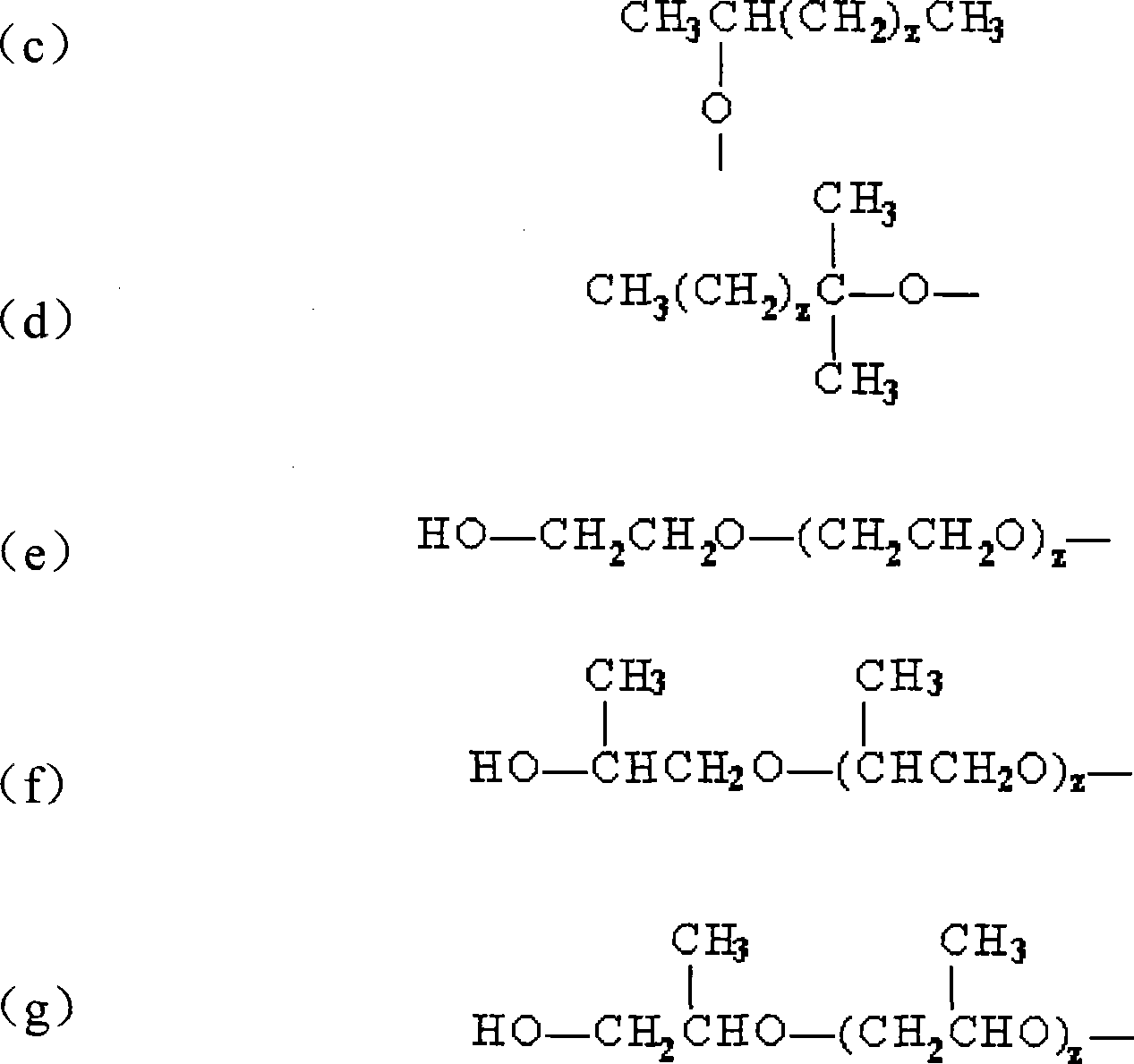

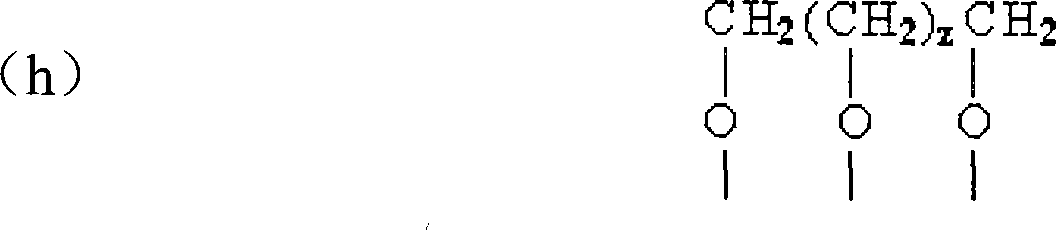

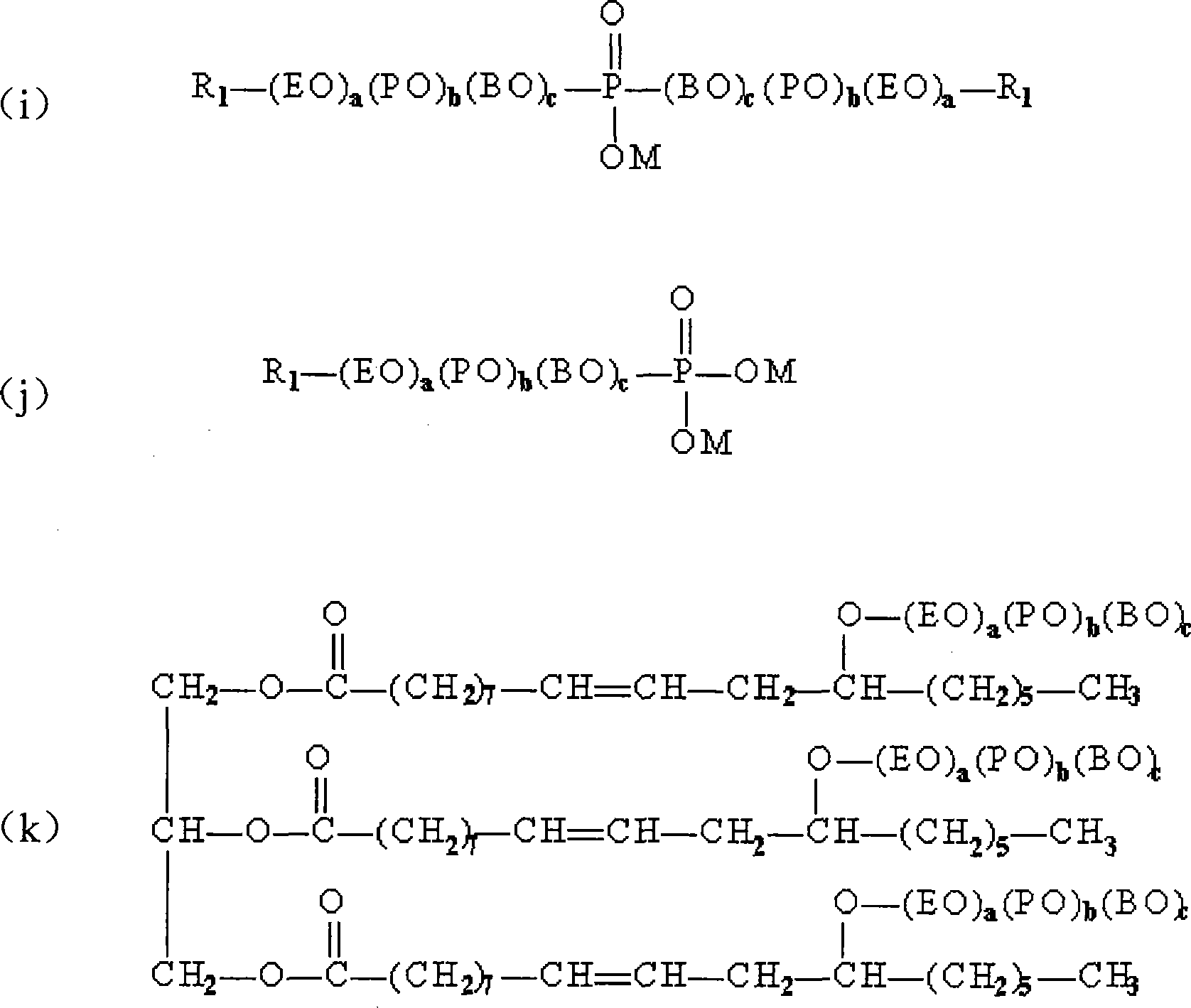

Method used

Image

Examples

Embodiment 1

[0052]1) Add 4.5kg of ethylene glycol and 0.1Kg of KOH to the high-pressure polymerization reactor of Baigang in vacuum, seal it, replace it with nitrogen, raise the temperature and start stirring. When the temperature in the kettle reaches 90-100°C, add 0.5Kg of propylene oxide. When the temperature rises and the pressure drops, continue to feed 18.5Kg of propylene oxide to control the reaction temperature at 120-160°C and the pressure in the kettle at 0.3- 0.6Mpa, when the addition of propylene oxide is completed, and the pressure in the kettle gradually drops to no longer drops for 30 minutes, add 0.5Kg of ethylene oxide, when the temperature rises and the pressure drops, continue to feed 72Kg of ethylene oxide Alkanes, control the reaction temperature at 120-160°C and the pressure in the kettle at 0.3-0.6Mpa. After the reaction is completed, the pressure in the kettle will gradually drop to no longer drop for 30 minutes, and the polyalkoxy compound component in the cutting ...

Embodiment 2

[0060] 1) In the high-pressure polymerization reactor of Baigang, add 2.5kg methanol and 0.1Kg KOH in vacuum, seal it, replace it with nitrogen, raise the temperature and start stirring. When the temperature in the kettle reaches 65-85°C, add a mixture of 0.25Kg ethylene oxide and 0.25Kg propylene oxide. When the temperature rises and the pressure drops, 17Kg of propylene oxide and 67.5Kg of epoxy are continuously introduced. Ethane mixture, the reaction temperature is controlled at 90-160°C and the pressure in the kettle is 0.3-0.6Mpa. When the mixture of ethylene oxide and propylene oxide is added and the pressure in the kettle gradually drops to 30 minutes without any further drop, the temperature will drop immediately. Obtain 87.5Kg of the polyalkoxy compound component monomer of cutting fluid, and its structural formula is: CH 3 O[(EO) 19.7 / (PO) 3.8 ]H

[0061] 2) At 30°C, add 2.5Kg of castor oil polyoxyethylene ether (EL-20) and 10Kg of propylene glycol to the monome...

Embodiment 3

[0064] 1) In a high-pressure polymerization reactor, add 12kg of isopropanol and 0.1Kg of KOH in vacuum, seal it, replace it with nitrogen, raise the temperature and start stirring. When the temperature in the kettle reaches 90-100°C, add 0.5Kg of ethylene oxide. When the temperature rises and the pressure drops, 80Kg of ethylene oxide is continuously introduced to control the reaction temperature at 120-160°C and the pressure in the kettle at 0.3 ~0.6Mpa, when the addition of ethylene oxide is completed, and the pressure in the kettle gradually drops to no longer drops for 30 minutes, add 0.5Kg propylene oxide, when the temperature rises and the pressure drops, continue to feed 6Kg of epoxy Propane, control the reaction temperature at 120-160°C and the pressure in the kettle at 0.3-0.6Mpa. After the reaction is completed, the pressure in the kettle will gradually drop to no longer drop for 30 minutes, and the polyalkoxy compound component of the cutting fluid will be obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com