Setup method for indium-gallium-nitride p-n node type multi-node solar battery structure

A multi-junction solar cell, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of ternary alloy research starting soon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

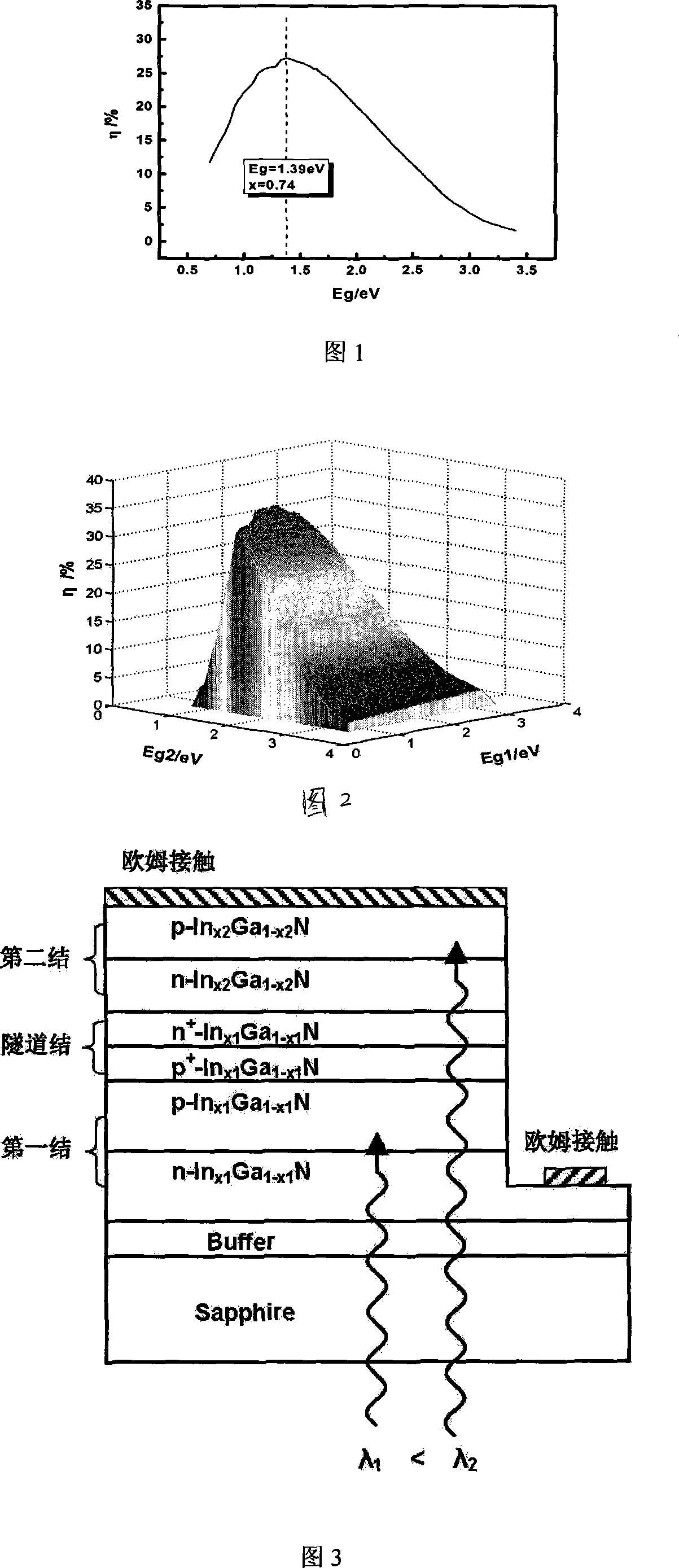

[0016] 1. Structure setup of InGaN p-n junction multi-junction solar cells

[0017] The multi-junction (including single-junction) solar cells need to use In with different In compositions. x Ga 1-x The determination process of N material and In composition is as follows: first calculate the maximum conversion efficiency, then obtain the optimal band gap of each material at this conversion efficiency, and finally obtain the corresponding In composition value. The theoretical calculation method of solar cell conversion efficiency is as follows: InGaN p-n junction solar cell satisfies the current-voltage equation of ideal p-n junction [1] , the following assumptions are made in the calculation process: 1) The structure of the solar cell is an ideal p-n junction; 2) The surface reflection of sunlight incident on the cell is ignored; 3) Each junction of the solar cell only absorbs energy greater than (including equal to, the same below) Photons with the forbidden band width of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com