Process for growing high-quality monocrystal indium nitride thin-film having double buffering layers

An indium nitride film, double buffer layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low ammonia cracking efficiency and insufficient source of five groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

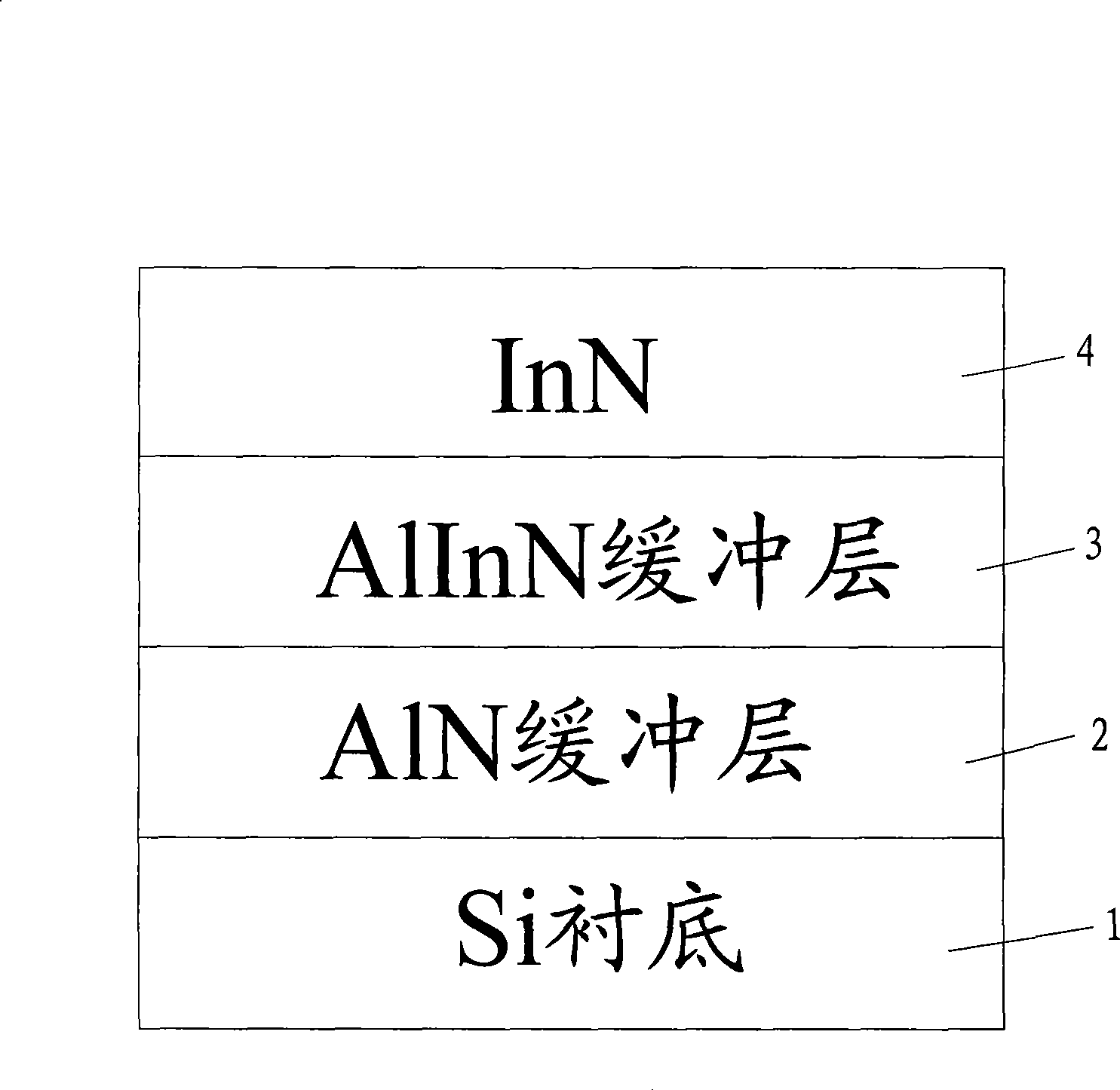

[0026] Such as figure 1 As shown, a method for growing high-quality single-crystal InN films with double buffer layers in the present invention is to utilize MOCVD (metal organic chemical vapor deposition) technology to grow AlN buffer layers 2 on silicon (Si) substrate 1. It is one of the keys of the present invention, continue to grow AlInN buffer layer 3 on AlN buffer layer 2, AlInN buffer layer 3 can be a layer of AlInN buffer layer of single composition, or a layer of AlInN buffer layer of graded composition, or different The multi-layer AlInN buffer layer of the composition, which is the second key of the present invention, finally grows the InN single crystal epitaxy 4 .

[0027] Concrete growth of the present invention comprises the following steps:

[0028] 1. In the MOCVD system, dehydrate the Si substrate 1 at a temperature of 300°C-1000°C, the carrier gas is hydrogen, the treatment time is 10 minutes-15 minutes, and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com