Process for preparing nitride ultromicro powder and nitride crystal wunder hydrothermal condition

A nitride, ultrafine powder technology, applied in chemical instruments and methods, nitrogen compounds, nitrogen-metal/silicon/boron binary compounds, etc. There are strict requirements and other problems to achieve the effect of easy monitoring and control, environmental protection, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

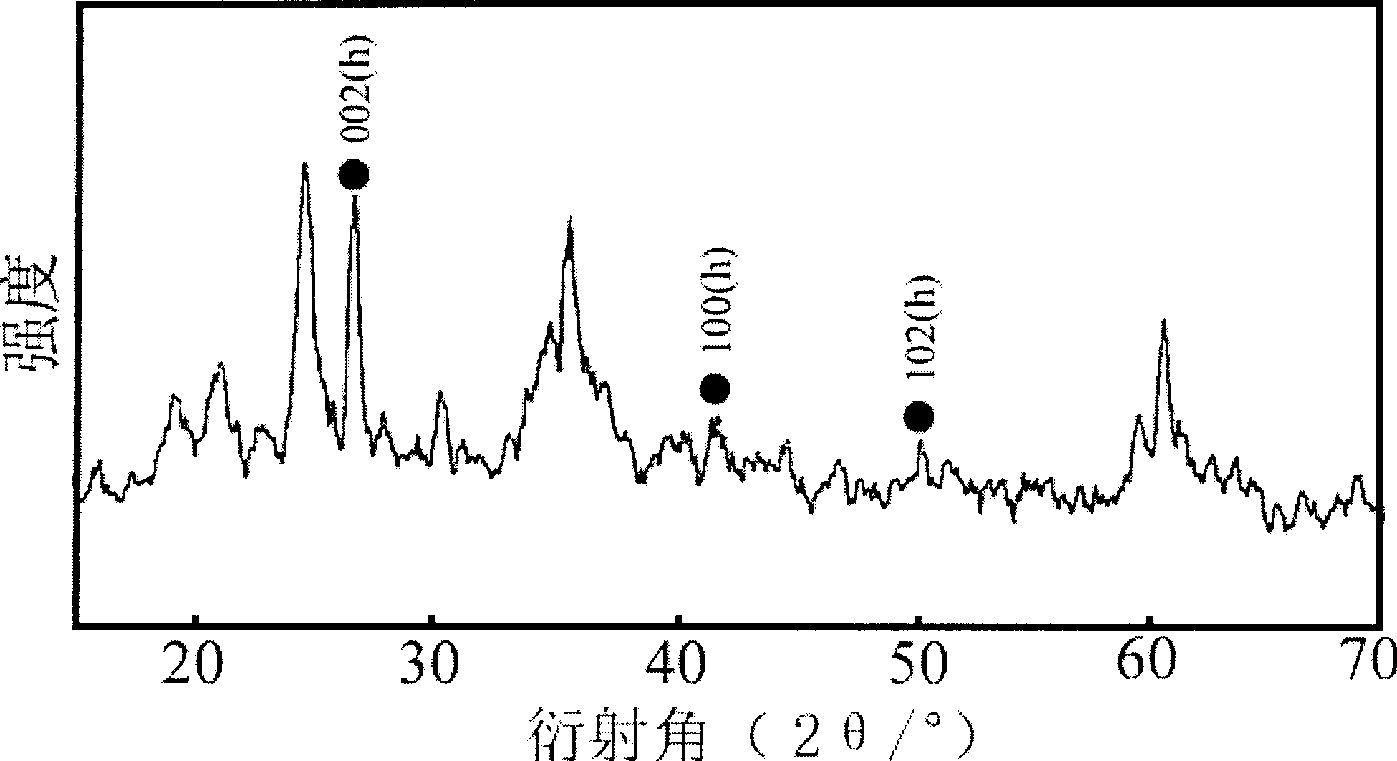

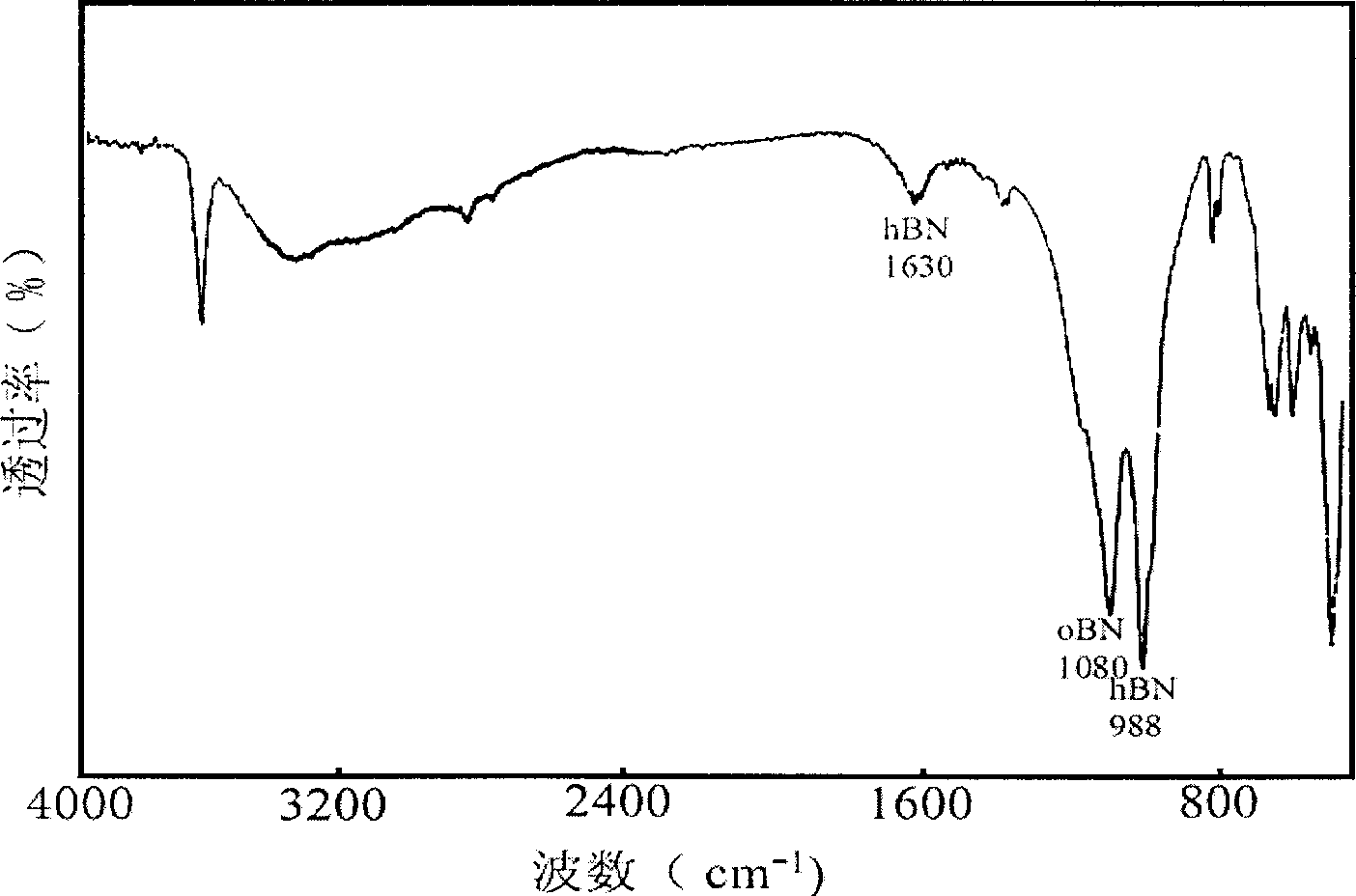

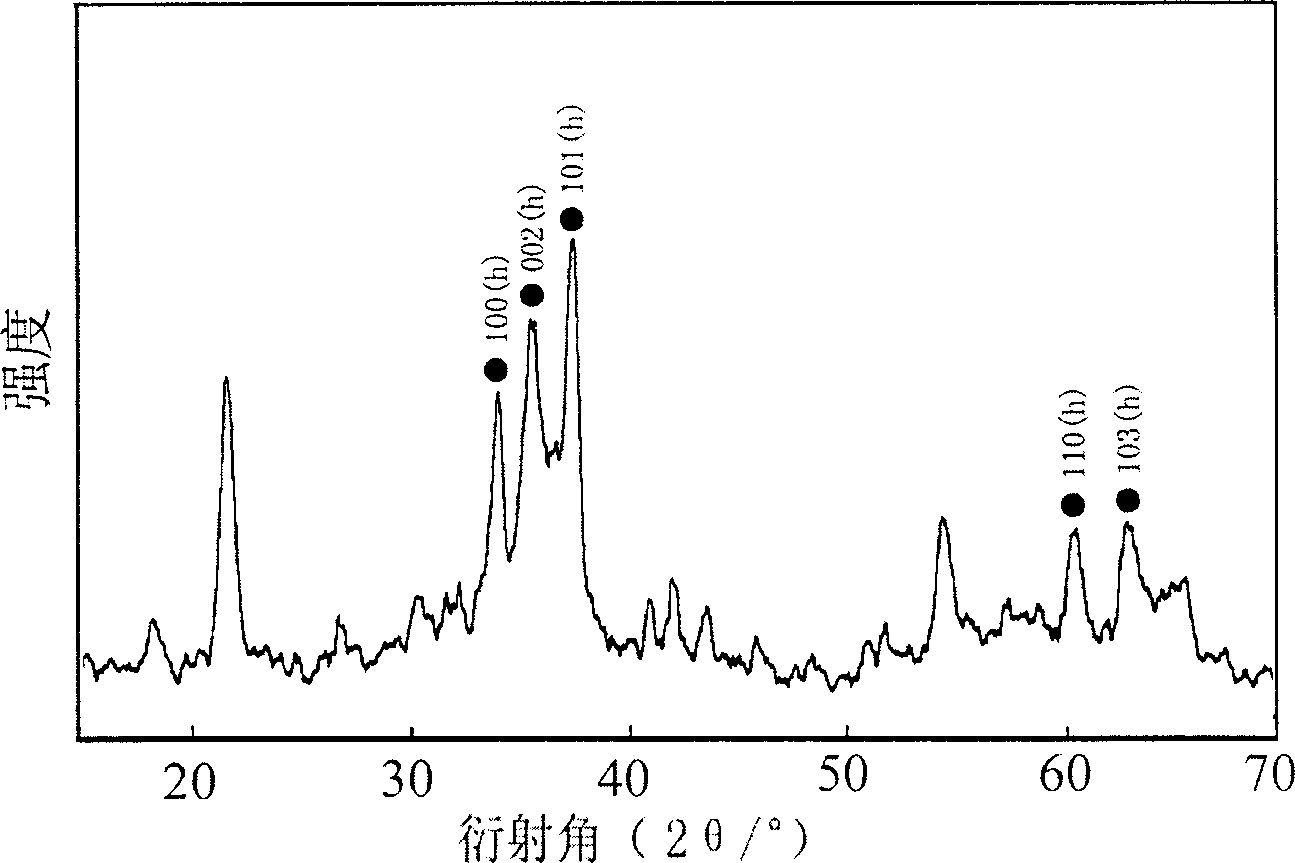

[0032] First, 120ml of water is added into a conical flask with a capacity of 250ml, and then 3.7g of boric acid (H 3 BO 3 ) into water, stirring while dissolving, and continuously stirring for 10 to 30 minutes to obtain a solution with a concentration of 0.5 mol / liter. With continuous stirring, 2.7 g of ammonium chloride (NH 4 Cl) was added to the boric acid solution obtained above. Then after stirring for 30 minutes, add 1.6g of phosphorus, continue stirring for 2 hours, transfer the uniformly stirred mixed solution to the reactor, then add water to make the filling rate reach 75%, seal the kettle, and heat the reactor to 400°C Keep warm for 10 hours. After the reaction was completed, the product was suction filtered, then washed with deionized water, and suction filtered several times until the filtrate was neutral. The obtained powder is heated and dried at 60° C. in a vacuum to obtain boron nitride micropowder with a particle size of nanometer. Embodiment 3. The thir...

Embodiment 3

[0033] Add 100ml of water into a conical flask with a capacity of 250ml, then dissolve 9.8g of sodium azide into the water, stir while dissolving, and add 3.5g of boron trioxide to the solution obtained above while stirring continuously . Add 1.6g of phosphorus, continue to stir for 2 hours, transfer the uniformly stirred mixed solution to the reactor, add water to make the filling rate reach 60%, seal the reactor, and heat the reactor to 350°C for 10 hours. After the reaction was completed, the product was filtered with deionized water several times until the filtrate was neutral. The powder thus obtained can be heated and dried in a vacuum to obtain boron nitride nanometer powder. Embodiment 4. Preparation four of boron nitride nanometer powder

Embodiment 4

[0034] 150ml of water is added into a 250ml Erlenmeyer flask, then 27g of sodium ammonium hydrogen phosphate is dissolved in water, and stirred while dissolving, and under continuous stirring, 3.5g of boron trioxide is added to the previously obtained solution. Then stir for 10 to 30 minutes, then add 5g of metal zinc powder, continue to stir for 0.5 to 2 hours, then transfer the evenly stirred mixed solution to the reaction kettle, then add water to make the filling rate reach 75%, seal the kettle, and put the reaction The kettle was heated to 450°C for 16 hours. Filter the product with deionized water until the filtrate is neutral. The obtained powder is heated in vacuum at 50-60 DEG C and dried to obtain boron nitride nanometer powder with a particle size of tens of nanometers. Embodiment 5. The fifth of the preparation of boron nitride nanopowder

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com