Water-base cutting liquid for hard and brittle materials and preparation method and application thereof

A technology of hard and brittle materials and cutting fluid, which is applied in the field of compound water-based cutting fluid and its preparation. It can solve the problems of sandy bottom, not easy to stir and redisperse, etc., and achieve low electrical conductivity and anti-sedimentation redispersion ability. Strong, strong heat carrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

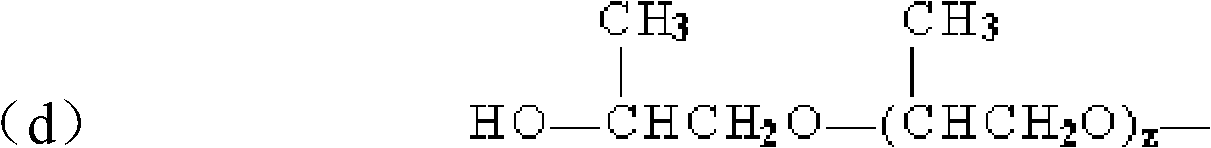

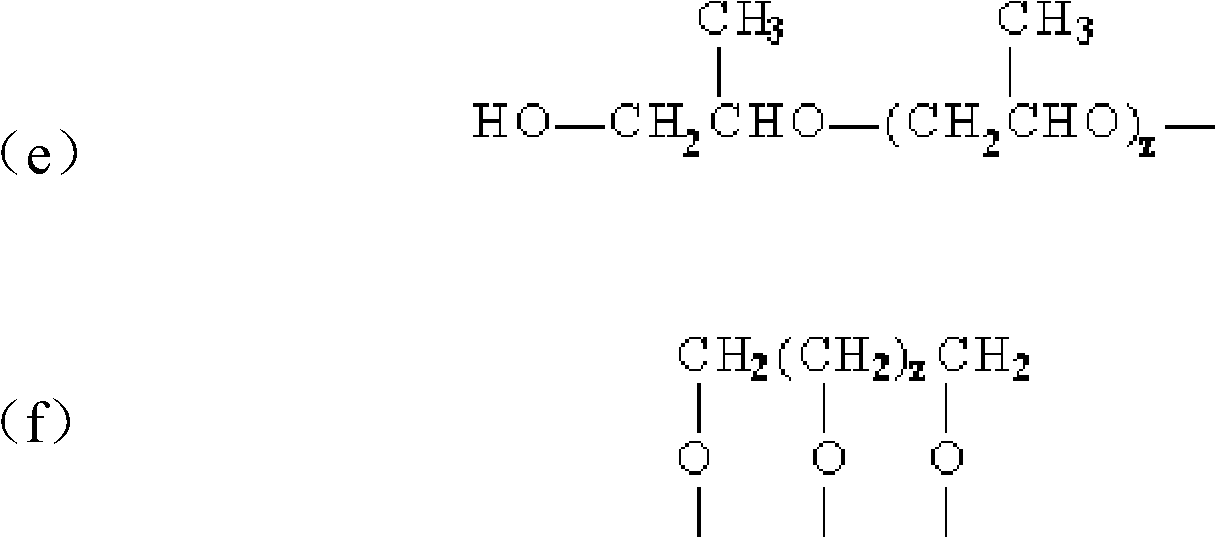

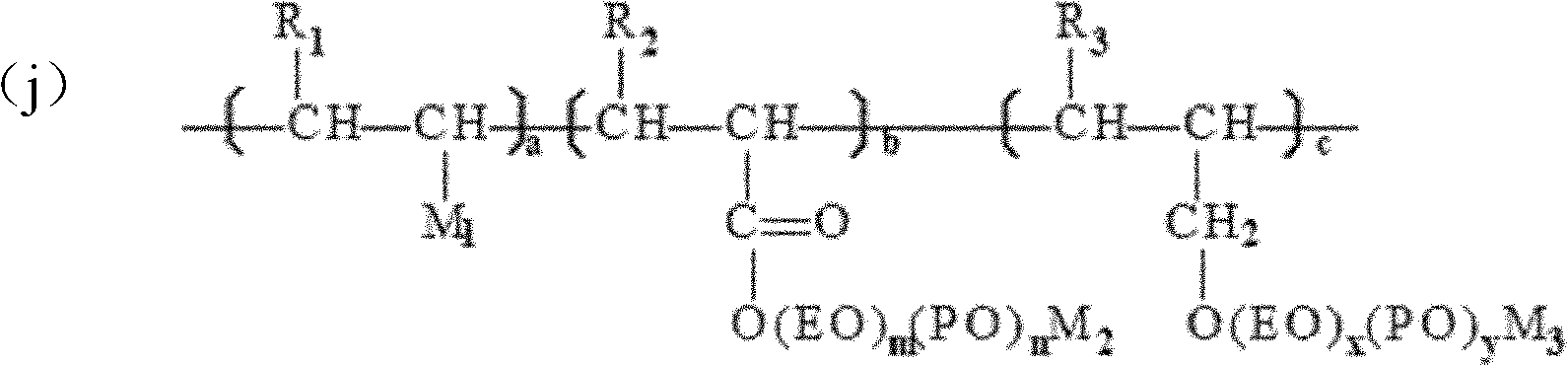

[0059] 1) Polycarboxylate polymer ether ester monomer A 1 Preparation of:

[0060] Add 58Kg propenyl alcohol, 1Kg potassium hydroxide catalyst into a 1.5 vertical high-pressure reactor, seal the equipment, then replace with nitrogen, raise the temperature, and feed a small amount of ethylene oxide when the temperature reaches 80°C. When the temperature rises and the pressure drops, continue Feed 880Kg of ethylene oxide, control the reaction temperature at 100-120°C and the reaction pressure of 0.5Mpa, after the completion of the reaction of ethylene oxide, heat preservation and aging for 30 minutes, feed a small amount of propylene oxide, when the temperature rises and the pressure drops , continue to feed 116Kg of propylene oxide, control the reaction temperature at 110-130°C and the reaction pressure of 0.4Mpa, after the reaction of propylene oxide is completed, after the heat preservation and aging for 30 minutes, adjust the pH value of the product to 5-7 with glacial aceti...

Embodiment 2

[0067] 1) Polycarboxylate polymer ether ester monomer A 2 Preparation of:

[0068] Add 25Kg propylene alcohol, 2Kg potassium hydroxide catalyst in 1.5 vertical high-pressure reactors, seal equipment, nitrogen replacement afterwards, heat up. 855Kg of ethylene oxide and 200Kg of propylene oxide are fully mixed in advance in the epoxy compound metering tank. When the temperature of the reactor reaches 80°C, feed a small amount of ethylene oxide and propylene oxide mixture. When the temperature rises and the pressure drops, continue to feed 1055Kg of epoxy mixture, and control the reaction temperature at 100-120°C and the reaction pressure at 0.4Mpa , after the reaction of the epoxy mixture is completed, after heat preservation and aging for 30 minutes, the pH value of the product is adjusted to 5-7 with lactic acid, and the temperature is lowered to discharge the material to obtain the polycarboxylate high polymer ether ester monomer A 2 .

[0069] 2) Anti-sedimentation redis...

Embodiment 3

[0075] 1) Polycarboxylate polymer ether ester monomer A 3 Preparation of:

[0076] Add 20g of allyl alcohol and 0.1g of potassium hydroxide catalyst into the high-pressure reactor, seal the equipment, replace with nitrogen, and raise the temperature. When the temperature reaches 80°C, a small amount of ethylene oxide is fed, and when the temperature rises and the pressure drops, 91g of ethylene oxide is continuously fed, and the reaction temperature is controlled at 100-120°C and the reaction pressure is 0.5Mpa, and the ethylene oxide reacts After the completion, heat preservation and aging for 30 minutes, adjust the pH value of the product to 5-7 with phosphoric acid, cool down and discharge, and obtain polycarboxylic acid high polymer ether ester monomer A 3 .

[0077] 2) Anti-sedimentation redispersant B 3 Preparation of:

[0078] Add 30g of monomer A in the normal pressure reactor 3 , 50g monomer A 1 , 5g maleic anhydride, 1g methacrylic acid, 86g water, stir to diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com