Chain piece with gorgeous color surface and mfg mehtod thereof

A manufacturing method and surface tool technology, applied in the field of chain pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

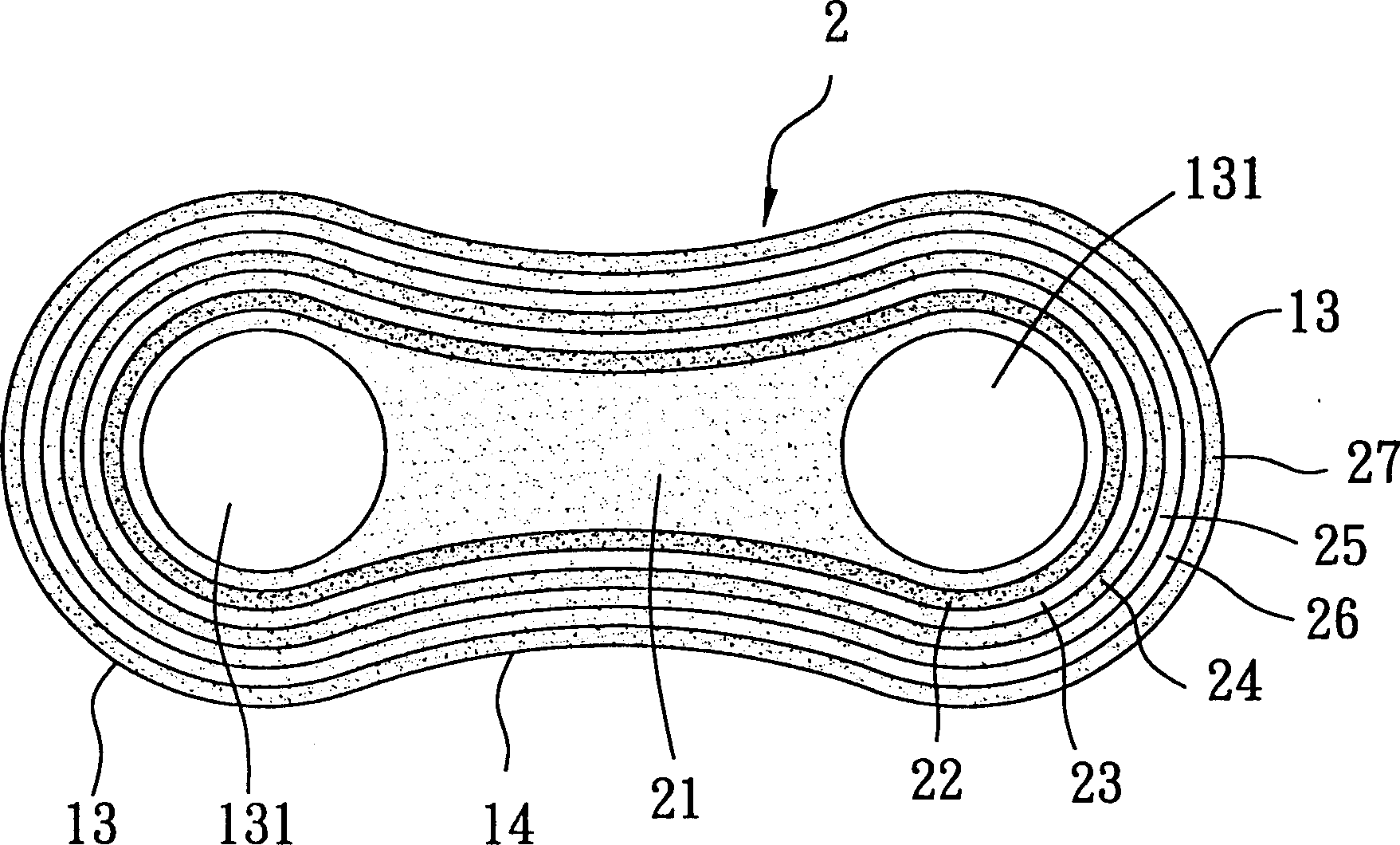

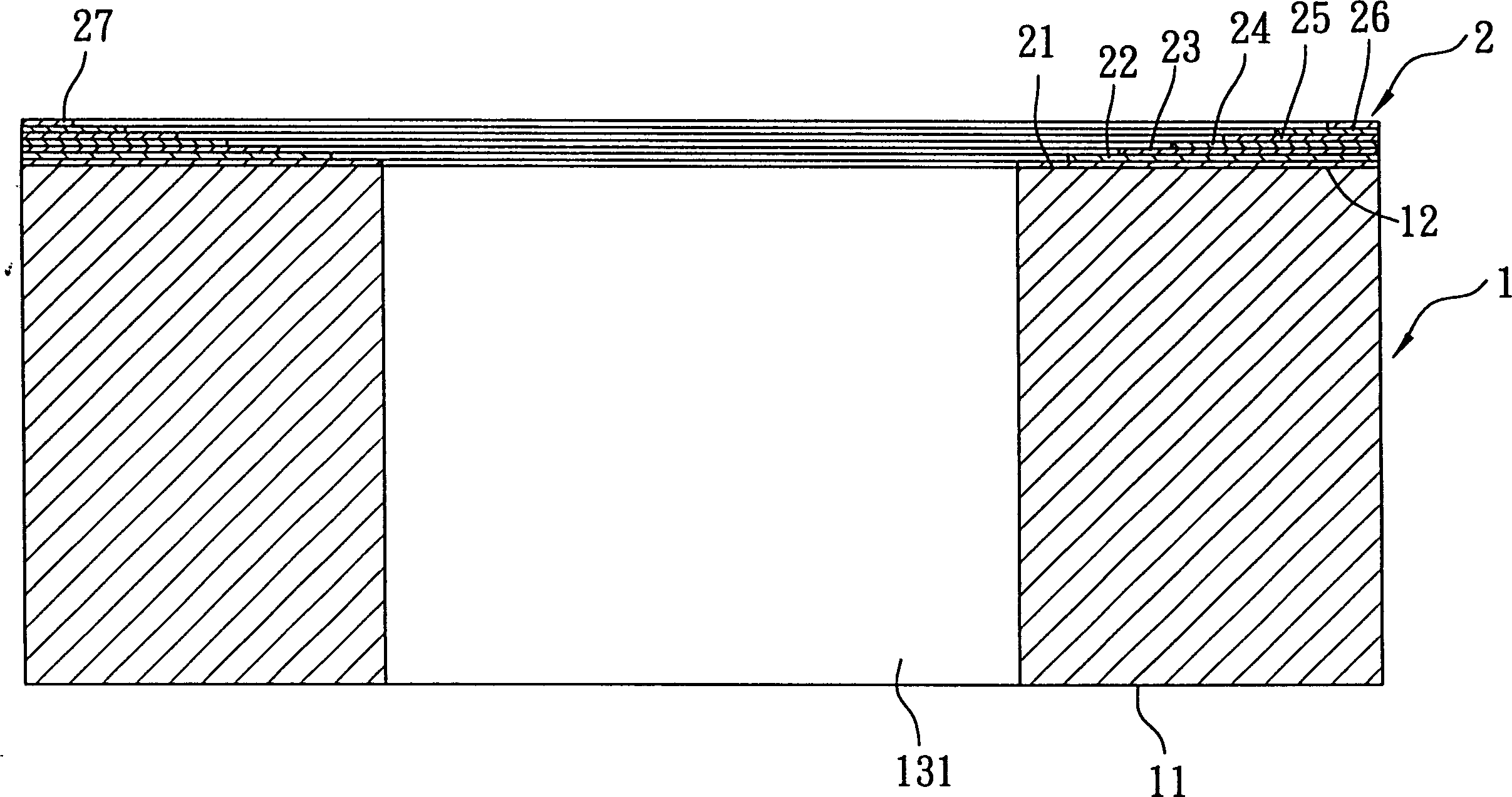

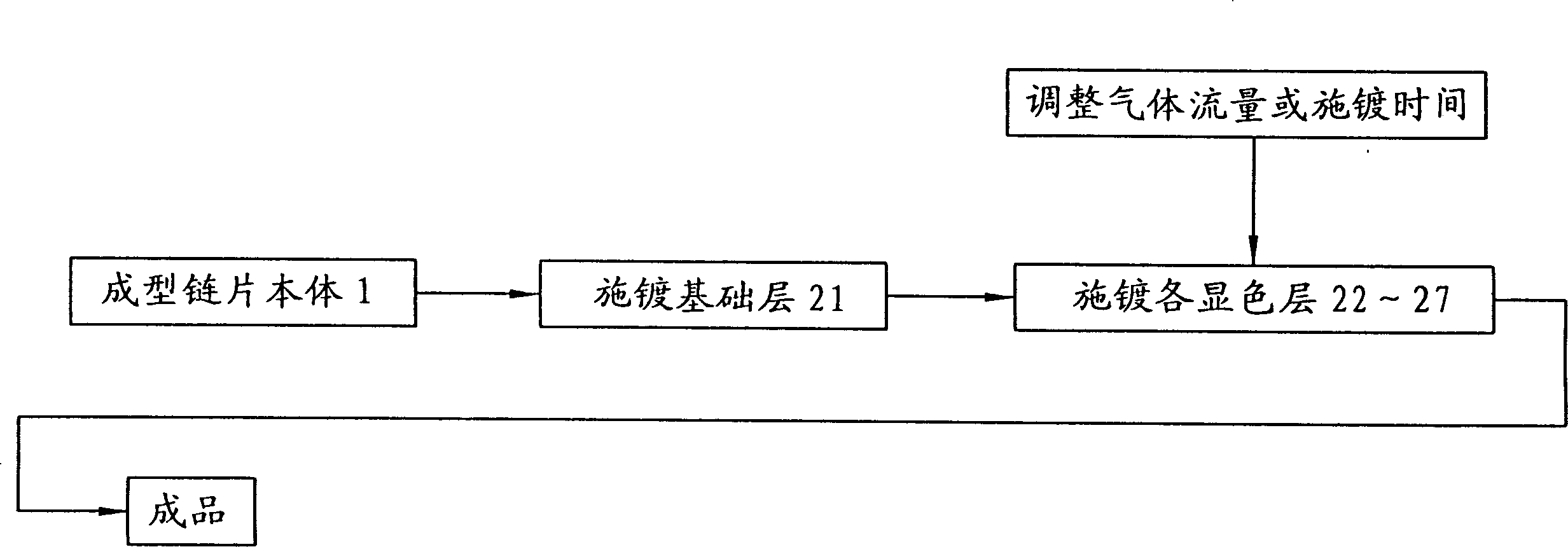

[0021] refer to figure 1 , 2 , the chain piece of the first preferred embodiment of the present invention is a design that can produce gorgeous colors like peacock feathers. In order to achieve the purpose of having brilliant colors, the chain piece includes: a metal chain piece body 1, and a physical A color coating unit 2 coated on the chain body 1 by vapor deposition method.

[0022] The chain piece body 1 is formed by die-cutting a metal steel plate, and has an inner surface 11, an outer surface 12 spaced inside and outside, two arc ends 13 between the two surfaces 11, 12 and spaced left and right, and A waist 14 connected between the two ends 13 but having a reduced width, wherein each end 13 includes a perforation 131 passing through the two surfaces 11 , 12 .

[0023] The color coating unit 2 is formed on the outer surface 12 of the link body 1 by cathodic arc discharge method in the physical vapor deposition method, and the color coating unit 2 has a base layer that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com