Process for producing aluminized paper by using aluminum foil as transfer base material

A production process, technology of aluminized paper, applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of high consumption of aluminum foil, lack of gloss effect of aluminum foil, etc., achieve high gloss effect, novel and unique production process, good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A production process of aluminized paper using aluminum foil as a transfer base material and preparation of a rubber material. The rubber material used in the process scheme is composed of a type A composite glue and a release aluminum foil precoating paint. The combination of type A composite glue and aluminum foil precoat paint forms the first precoat stripping process. Specifically include the following steps:

[0083] 1. Preparation of type A glue

[0084] Type A glue preparation includes the following process steps:

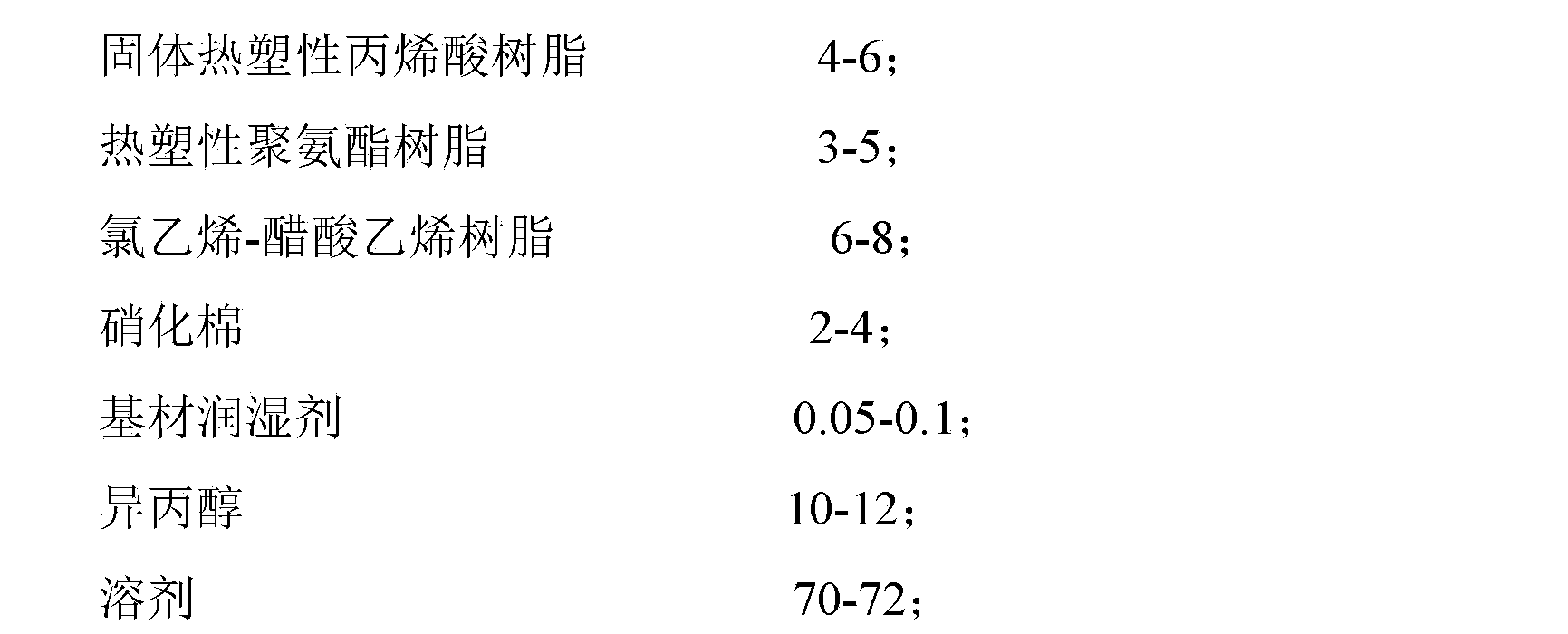

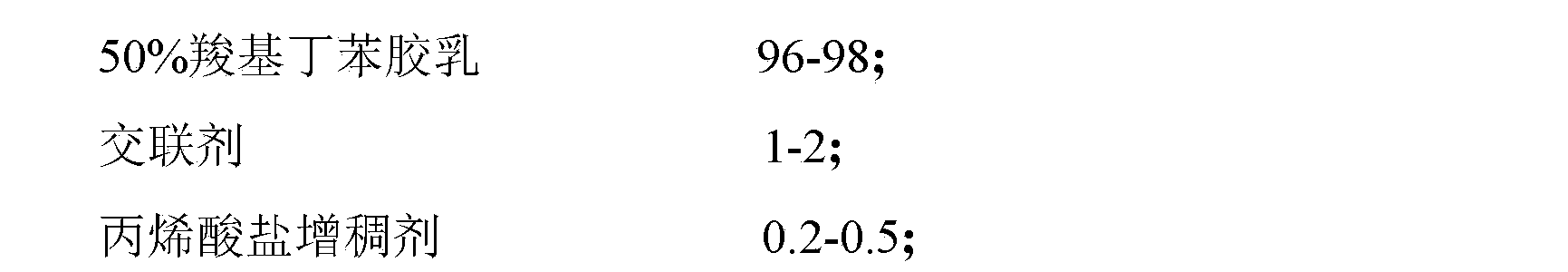

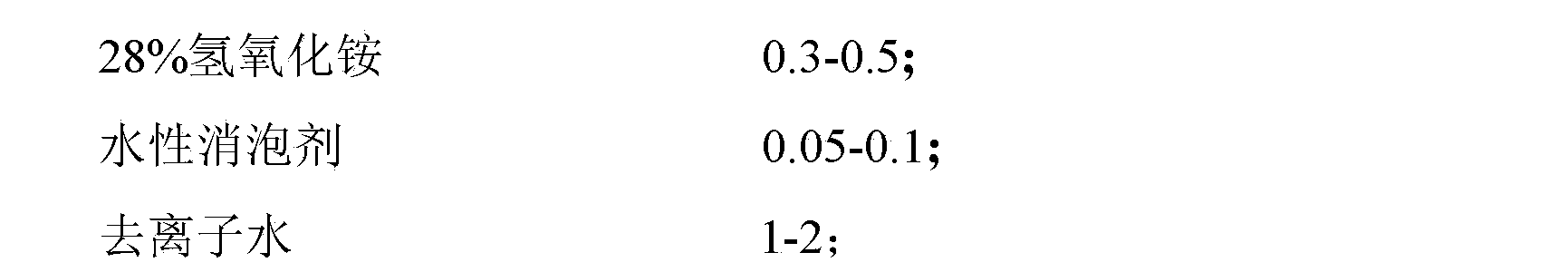

[0085] (1) Prepare materials according to the following components and contents (weight, kilogram):

[0086] 50% carboxylated styrene-butadiene latex 96-98;

[0087] Crosslinking agent 1-2;

[0088] Acrylate thickener 0.2-0.5;

[0089] 28% ammonium hydroxide 0.3-0.5;

[0090] Water-based defoamer 0.05-0.1;

[0091] Deionized water 1-2

[0092] The 50% carboxylated styrene-butadiene latex is BASF SD516, the cross-linking agent is Cytec water-ba...

Embodiment 2

[0117] A production process of aluminized paper with aluminum foil as a transfer base material and preparation of rubber material. The process scheme is directly combined with type B composite glue and aluminum foil to form the second direct peeling process.

[0118] The composite machine that assists the above-mentioned direct peeling process needs to be equipped with a refrigeration device and a refrigeration unit. The cooling fluid is injected into the cooling roller of the composite machine through the interface of the refrigeration unit. During normal production and operation, the temperature of the cooling roller surface is kept at 0-10°C.

[0119] Specifically include the following steps:

[0120] 1. Preparation of type B glue

[0121] (1) Prepare materials according to the following components and contents (weight, kilogram):

[0122] 50% polyvinyl acetate emulsion 55-60;

[0123] 46% benzene-acrylic emulsion 30-35;

[0124] Cross-linking agent 2-3;

[0125] Water-...

Embodiment 3

[0136] A production process of aluminized paper using aluminum foil as a transfer base material and preparation of rubber material. The process plan is to directly compound the B-type composite glue and the matte surface of aluminum foil to form the second direct peeling process. The stripped paper is printed with transparent varnish by gravure.

[0137] 1. The preparation of type B glue includes the following process steps:

[0138] (1) Prepare materials according to the following components and contents (weight, kilogram):

[0139] 50% polyvinyl acetate emulsion 55-60;

[0140] 46% benzene-acrylic emulsion 30-35;

[0141] Cross-linking agent 2-3;

[0142] Water-based defoamer 0.02-0.05;

[0143] Deionized water 2-10;

[0144] The 50% polyvinyl acetate emulsion is Beijing Organic Chemical JD02, the 46% benzene-acrylic emulsion is Johnson J89, the crosslinking agent is Cytec water-based amino resin 373, and the water-based defoamer is TEGO Airex901w;

[0145] (2) 50% pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com