Method for preparing nitrogen oxygen zinc thin film

A technology of zinc oxynitride and thin film, which is applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problems of low solid solubility, high carrier mobility, low resistivity, etc., and achieve migration High efficiency, good stability, and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

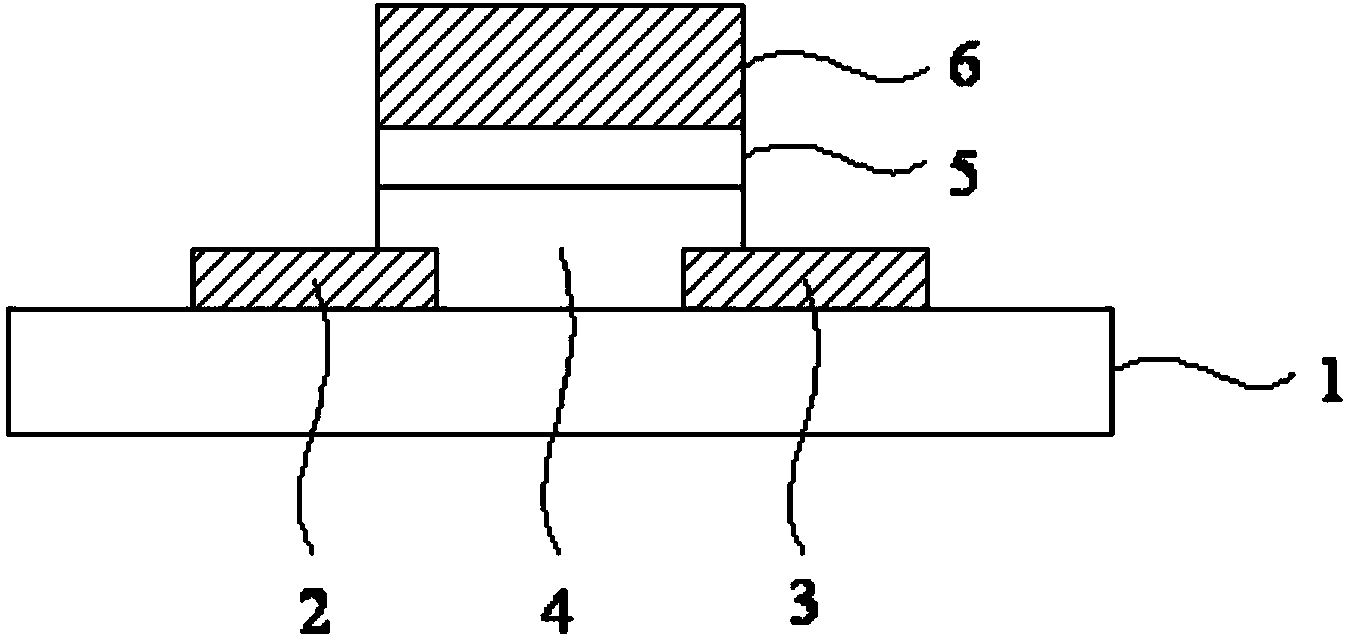

[0022] The present invention provides a kind of preparation method of zinc oxynitride film, in one embodiment, comprises the following steps:

[0023] Using radio frequency magnetron sputtering, the zinc nitride target with a volume percentage of 99.9-99.999% is used as the sputtering target, and the distance between the sputtering target and the substrate is 20-150mm. 99.9-99.999% argon is the sputtering gas, the substrate temperature is 25-150°C, at 0.5-5W / cm 2 Sputtering is carried out under a certain power density, and the background vacuum of the sputtering chamber is less than 1×10 -7 Torr, first pre-sputter with the argon gas for a period of time, and then use oxygen with a volume percentage of 99.9-99.999% as the reaction gas, the oxygen flow rate is 0.1-60 sccm, the argon gas flow rate is 5-100 sccm, and the sputtering pressure is controlled at 0.1 Between -10.0Pa, the zinc oxynitride thin film is obtained. In the zinc oxynitride thin film, the number of Zn atoms acc...

Embodiment 1

[0032] Using radio frequency magnetron sputtering, 99.99% zinc nitride target is used as the sputtering target, the distance between the zinc nitride target and the substrate is 60mm, the radio frequency frequency is 13.56MHz, and 99.999% argon is used as the sputtering gas, 99.999 % oxygen is the reaction gas, and the proportion of the gas is controlled by the gas flow meter. The substrate temperature was kept at 25°C during sample growth, and the sputtering power density was 2W / cm 2 , the background vacuum of the sputtering chamber is 0.8×10 -7 Torr, pre-sputtering 10min. The flow rate of oxygen gas is 6 sccm, no nitrogen gas is introduced, the flow rate of argon gas is 20 sccm, and the sputtering pressure is 1.3 Pa.

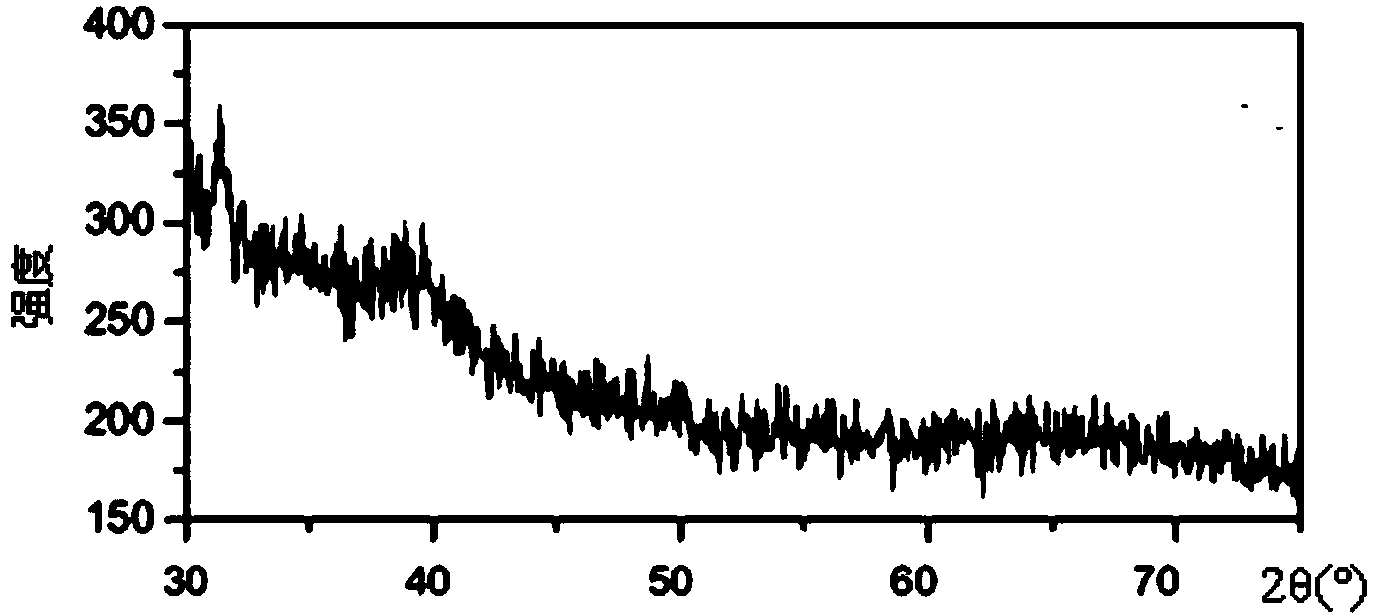

[0033] In the chemical composition of the prepared film, the number of Zn atoms accounts for 58%, and the atomic number ratio of nitrogen and oxygen is N:O=1:1. The Accent HL5500PC Hall effect test system was used to test the carrier concentration and Hall ...

Embodiment 2

[0044] Using radio frequency magnetron sputtering, 99.99% zinc nitride target is used as the sputtering target, the distance between the zinc nitride target and the substrate is 60mm, the radio frequency frequency used is 13.56MHz, and 99.999% argon is used as the sputtering gas , 99.999% of the oxygen is the reaction gas, and the proportion of the gas is controlled by the gas flow meter. The substrate temperature was kept at 25°C during sample growth, and the sputtering power was 3.3W / cm 2 , the background vacuum of the sputtering chamber is 0.9×10 -7 Torr, pre-sputtering 10min. The oxygen flow rate is 1 sccm, the nitrogen gas is not fed, the argon gas flow rate is maintained at 50 sccm, and the sputtering pressure is 1.5 Pa.

[0045] In the chemical composition of the prepared film, the number of Zn atoms accounts for 66%, and the atomic number ratio of nitrogen and oxygen is N:O=2:1. The Accent HL5500PC Hall effect test system was used to test the carrier concentration a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com