A metal surface treatment passivation solution

A technology of metal surface treatment and passivation solution, applied in the direction of metal material coating process, etc., to achieve the effect of excellent corrosion resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

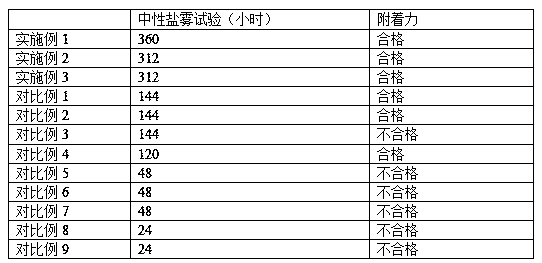

Examples

Embodiment 1

[0058] Passivation solution composition: 10g / L zinc nitrate, 20g / L phosphoric acid, 30g / L dispersant sodium ethylenediamine tetramethylene phosphonate and 5g / L modified mesoporous silica A1.

Embodiment 2

[0060] Passivation solution composition: 10g / L zinc nitrate, 20g / L phosphoric acid, 30g / L dispersant sodium ethylenediamine tetramethylene phosphonate and 5g / L modified mesoporous silica A2.

Embodiment 3

[0062] Passivation solution composition: 20g / L zinc nitrate, 30g / L phosphoric acid, 40g / L dispersant sodium ethylenediamine tetramethylene phosphonate and 5g / L modified mesoporous silica A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com