Preparation method of biomass quick burning bricks and device

A biomass and quick-burning brick technology, which is applied in the directions of biofuel, waste fuel, fuel, etc., can solve the problems of environmental pollution, waste of biomass burning heat, etc., and achieve the effects of high preparation efficiency, convenient ignition and fast burning speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of biomass fast-burning bricks, comprising the following steps:

[0024] Step 1, drying the biomass after removing impurities;

[0025] Step 2, adding sodium bicarbonate, potassium permanganate, zeolite powder, sodium silicate and fatty alcohol polyoxyethylene ether sodium sulfate to the dried biomass, and mixing uniformly to obtain a mixture 1;

[0026] Step 3, heating the mixture 1 to 60-65°C, keeping it warm for 30-40 minutes, then raising the temperature to 300-360°C, and keeping it for 60-80 minutes to obtain the mixture 2;

[0027] Step 4, pulverizing the mixture 2, then adding water, zinc nitrate, calcium oxide, bentonite, epoxy resin, gum arabic and xanthan gum, and mixing evenly to obtain the mixture 3;

[0028] In step 5, the temperature of the mixture 3 is raised to 75-80° C. and then extruded to obtain a biomass fast-burning brick.

[0029] The mass ratio of adding sodium bicarbonate, potassium permanganate, zeolite powder, sodium sili...

Embodiment 2

[0031] A preparation method of biomass fast-burning bricks, comprising the following steps:

[0032] Step 1, drying the biomass after removing impurities;

[0033] Step 2, adding sodium bicarbonate, potassium permanganate, zeolite powder, sodium silicate and fatty alcohol polyoxyethylene ether sodium sulfate to the dried biomass, and mixing uniformly to obtain a mixture 1;

[0034] Step 3, heating mixture 1 to 65-70°C, keeping it warm for 40-50 minutes, then raising the temperature to 360-400°C at a heating rate of 8-10°C / min, and keeping it for 80-100 minutes to obtain mixture 2;

[0035] Step 4, pulverizing the mixture 2, then adding water, zinc nitrate, calcium oxide, bentonite, epoxy resin, gum arabic and xanthan gum, and mixing evenly to obtain the mixture 3;

[0036] In step 5, the temperature of the mixture 3 is raised to 75-80° C. and then extruded to obtain a biomass fast-burning brick.

[0037] The mass ratio of adding sodium bicarbonate, potassium permanganate, ze...

Embodiment 3

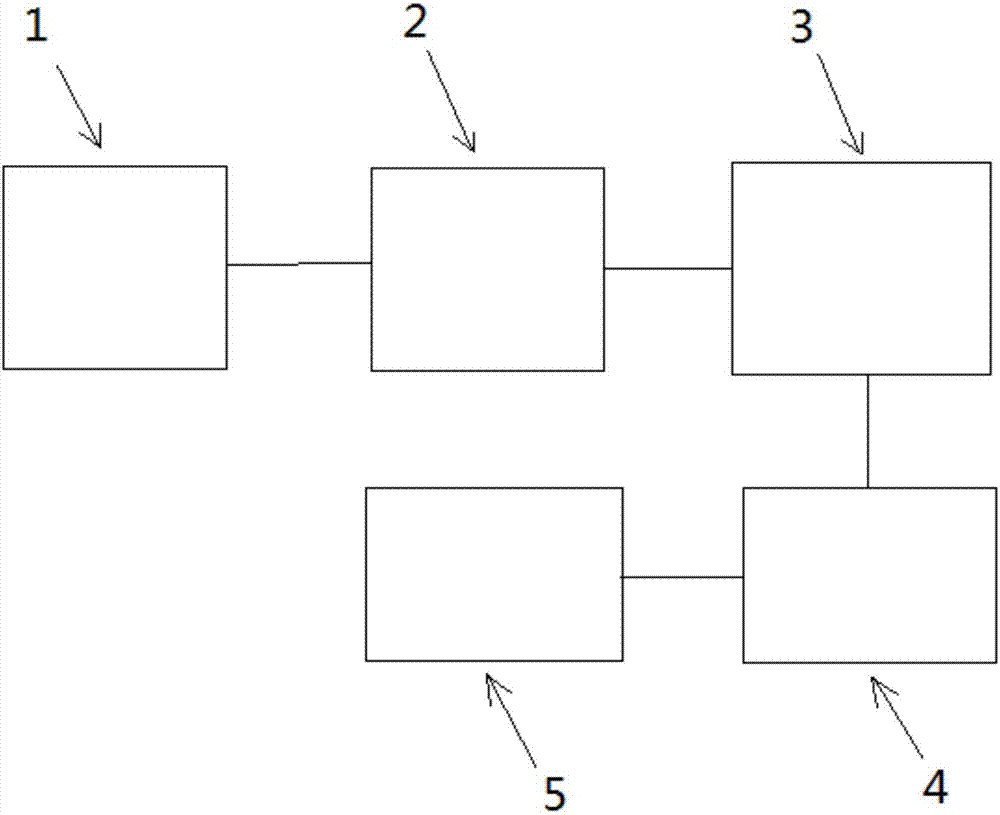

[0039] This embodiment provides a device for preparing biomass fast-burning bricks, such as figure 1 As shown, it includes a drying unit 1, a mixing unit 2, a reaction unit 3, a pulverizing unit 4 and an extrusion molding unit 5 connected in sequence, and the connection between the units is through a conveyor belt. In this embodiment, the drying unit is a dryer, the mixing unit is a mixing mixer, the reaction unit is a high-temperature reactor, the crushing unit is a pulverizer, and the extrusion molding unit is an extrusion molding machine.

[0040] All the units in the above device use the existing equipment, and the equipment cooperates with each other to achieve a good preparation effect. The use process of the above device is matched with Embodiments 1 and 2, and the biomass fast-burning brick can be prepared well. The preparation process can be fully automated and controlled, and the preparation efficiency is high.

[0041] The biomass quick-combustible bricks obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com