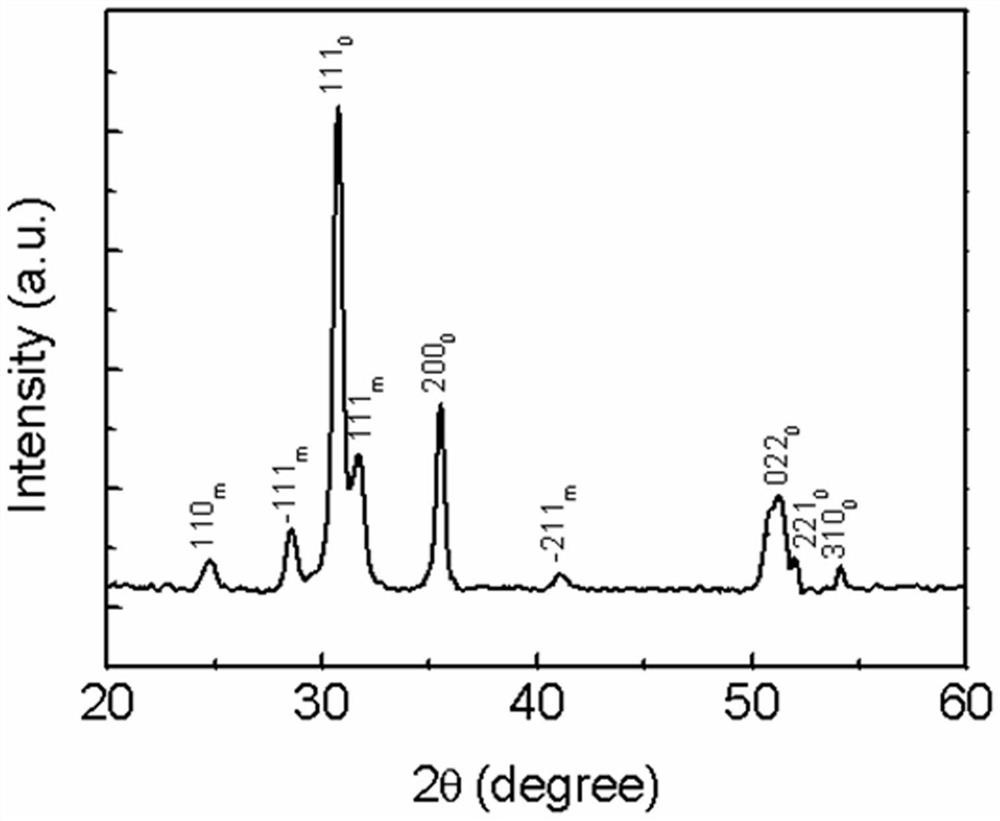

Method for low-temperature preparation of hafnium oxide-based ferroelectric film through ion beam assisted magnetron sputtering deposition

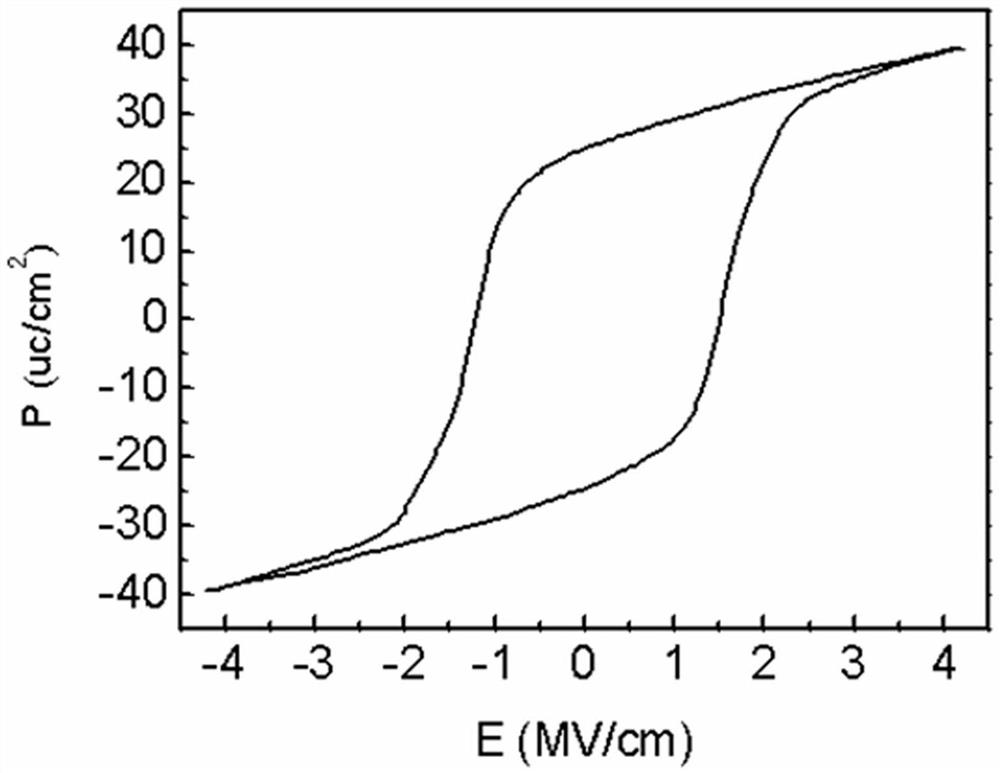

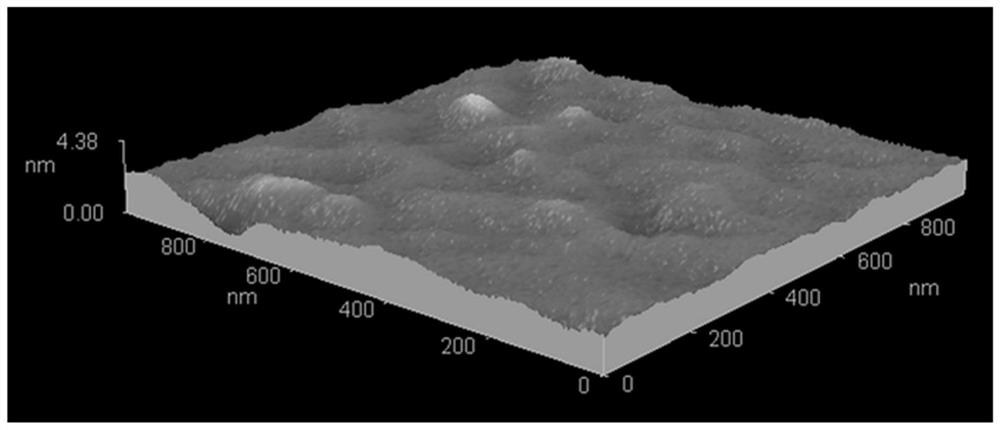

An ion beam-assisted, magnetron sputtering technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve the problems of uneven film composition and high substrate temperature, and achieve high remanent polarization strength, Low leakage, smooth and compact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Select the plexiglass coated with ITO conductive film as the substrate, first clean the substrate, then dry it with nitrogen, send it into the sputtering chamber, and use a vacuum pump to pump the sputtering chamber to a high vacuum. Pre-sputtering is carried out before sputtering deposition, specifically, high-purity argon gas is introduced to HfO 2 target and Y 2 o 3 The target is pre-sputtered and then co-sputtered. The purity of argon used in the experiment is 99.99%, HfO 2 target and Y 2 o 3 The purity of the target material is 99.99%, and the background vacuum degree of thin film sputtering deposition is 3×10 -4 Pa, the target base distance is 50mm. During target pre-sputtering and film sputtering deposition, the chamber pressure is 0.3Pa, the substrate is not heated, the argon gas flow rate is 20 sccm, HfO 2 Target sputtering power is 50W, Y 2 o 3 The target sputtering power is 10W, the ion beam energy is 800eV during the sputtering deposition of thin fi...

Embodiment 2

[0048] Select a p-type Ge(111) single wafer as the substrate, first clean the substrate, then dry it with nitrogen, send it into the sputtering chamber, and use a vacuum pump to evacuate the sputtering chamber to a high vacuum. Pre-sputtering is carried out before sputtering deposition, specifically, high-purity argon gas is introduced to HfO 2 Target and SiO 2 The target is pre-sputtered and then co-sputtered. The purity of argon used in the experiment is 99.99%, HfO 2 Target and SiO 2 The purity of the target material is 99.99%, and the background vacuum degree of thin film sputtering deposition is 3×10 -4 Pa, the target base distance is 50mm. During target pre-sputtering and film sputtering deposition, the chamber pressure is 0.3Pa, the substrate is not heated, the argon gas flow rate is 20 sccm, HfO 2 Target sputtering power is 50W, SiO 2 The target sputtering power is 12W, the ion beam energy is 1200eV during the film sputtering deposition, the target pre-sputtering...

Embodiment 3

[0050] Select a p-type Si(100) single wafer as the substrate, remove the pollutants and oxide layer on the surface of the Si wafer by RAC cleaning process, then dry it with nitrogen, send it into the sputtering chamber, and use the vacuum pump to evacuate the sputtering chamber to high vacuum. In order to remove impurities on the target surface, pre-sputtering is carried out before thin film sputtering deposition, specifically, high-purity argon gas is introduced to the Pt target, HfO 2 target and ZrO 2 The target is pre-sputtered, followed by Pt bottom electrode, Zr-doped HfO 2 Preparation of Ferroelectric Thin Film and Pt Top Electrode to Get Pt-Zr Doped HfO 2 Capacitors based on ferroelectric thin film-Pt structures. The purity of argon gas used in the experiment is 99.99%, Pt target material, HfO 2 Target and ZrO 2 The purity of the target material is 99.99%, and the background vacuum degree of the thin film deposition and sputtering product is 3×10 -4 Pa, the target ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanent polarization | aaaaa | aaaaa |

| Surface root mean square roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com