Preparation methods of ZnO base powder target and thin film transistor active layer

A thin-film transistor and powder target technology, which is applied in coating, metal material coating process, ion implantation plating, etc., can solve problems such as easy cracking during use, complex target manufacturing process, and easy introduction of impurities, etc., to achieve optimization The device structure and deposition conditions of each layer, the effect of performance index improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

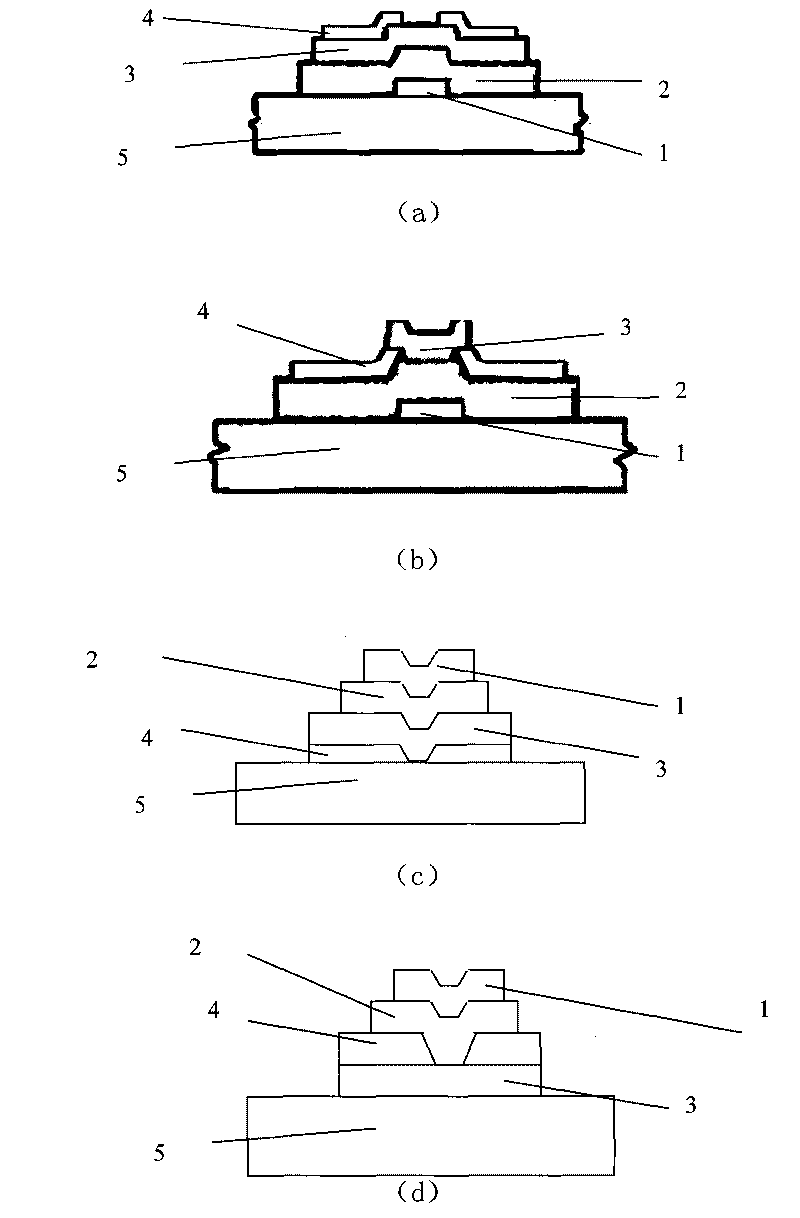

[0039] This example is about the detailed process of ZnO-based powder target preparation and TFT device manufacturing.

[0040] 1. Preparation of powder target

[0041] 1) Preparation of mixed powder

[0042] Put the required ZnO powder (purity 4N), or doped Ga 2 o 3 、In 2 o 3 (Purity is 5N) ZnO powder (Ga 2 o 3 : In 2 o 3 : ZnO molar ratio is 0.5: 0.5: 1.0), put it into a cleaned ball mill jar, and put an agate ball with a diameter of about 1 cm, using analytical pure ethanol as the medium, the mass ratio of ball: material: medium is about 2: 1 : 1, ball milled on a roller ball mill for 5 hours, then poured the mixed slurry into a glass beaker and dried at 180-200°C.

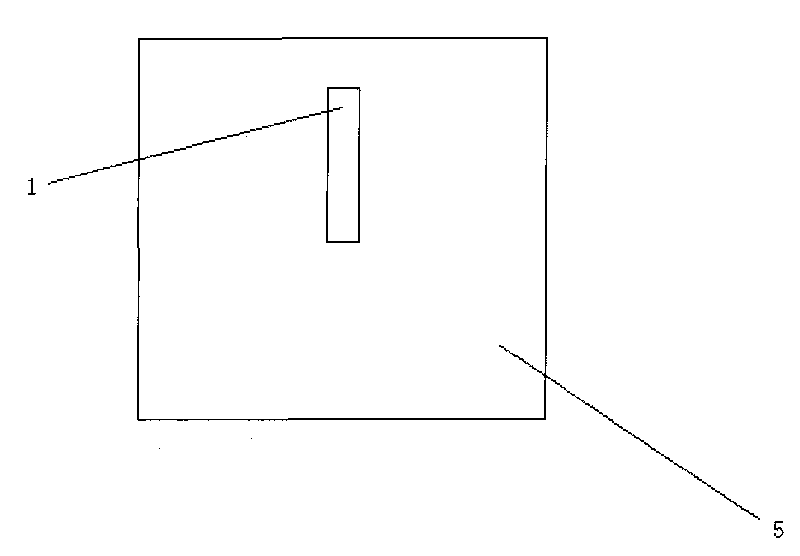

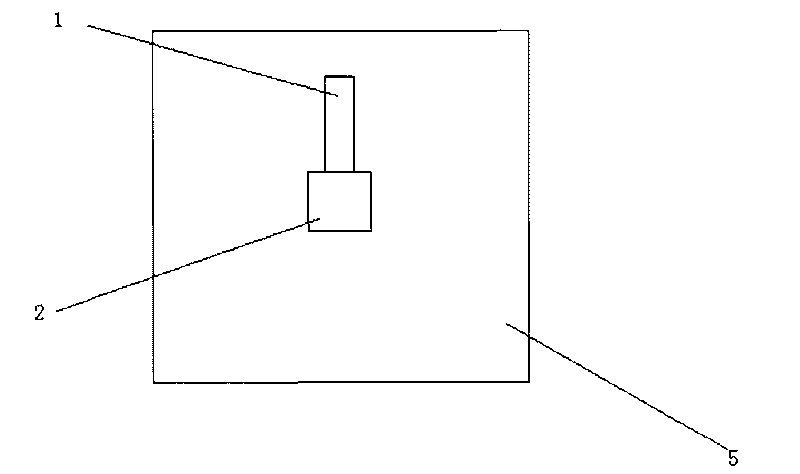

[0043] 2) Powder filling seat and pressure head production

[0044] Process the aluminum alloy packing groove (the material is provided by Shanghai Lizhi Materials Co., Ltd., model 7009), an aluminum alloy disc with a thickness of 7mm and a diameter of 7.6cm, and a concentric groove is milled in the m...

Embodiment 2

[0059] For a top-gate TFT device with IGZO as the active layer, the ratio of width (W) / length (L) of the device channel is 200 μm / 25 μm. The pattern of each layer is obtained by using a SUS430 stainless steel mask plate with a thickness of 50 μm. In order to reduce the gap between the mask and the substrate, a strong magnet of the same size is placed on the back of the substrate. Glass substrate using CorningEagle 2000, size 35×35mm 2 , after cleaning according to standard steps (see: Chinese patent, application number: 200810032549.3). The source-drain Ni electrode with a thickness of 40nm is evaporated by electron beam, and the deposition equipment is ZZSX-800 electron beam coating machine, and the vacuum degree of the chamber during deposition is 3.5×10 -3 Pa. Then, a 40nm IGZO thin film was deposited as an active layer using a powder target, and the deposition equipment was a CS500 radio frequency magnetron sputtering apparatus. The diameter of the target is 3 inches, a...

Embodiment 3

[0066] For a top-gate TFT device with IGZO as the active layer, the ratio of width (W) / length (L) of the device channel is 200 μm / 50 μm. The test of glass substrate and cleaning method, source-drain electrode, active layer, gate dielectric, gate electrode material and deposition method, thickness and electrical performance characteristics are all the same as in Example 2 except for the differences described below . The thickness of the IGZO active layer is 50nm, and the background vacuum during deposition is 7.4×10 -4 Pa, Ar / M (M stands for Ar and O 2 mixed gas, O 2 The content is 4.7%), the flow ratio is 120sccm / 5sccm, the air pressure is 1.4Pa, the power is 150W, the substrate temperature is about 20°C, the target-base distance is 6.4cm, and the deposition rate is 9.8nm / min. Gate dielectric uses Al 2 o 3 (70nm) / sialon (400nm) composite structure, the deposition power of sialon is 400W, the deposition rate is 10.9nm / min, and the rest are the same as in Example 2. al 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electrical breakdown strength | aaaaa | aaaaa |

| Field effect mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com