Nano pitch templet and preparation method thereof

A pitch and template technology, applied in the field of nano-pitch template and its preparation, can solve the problems of low processing speed, harsh processing conditions, poor repeatability, etc., and achieve the effect of small nominal pitch and widening application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

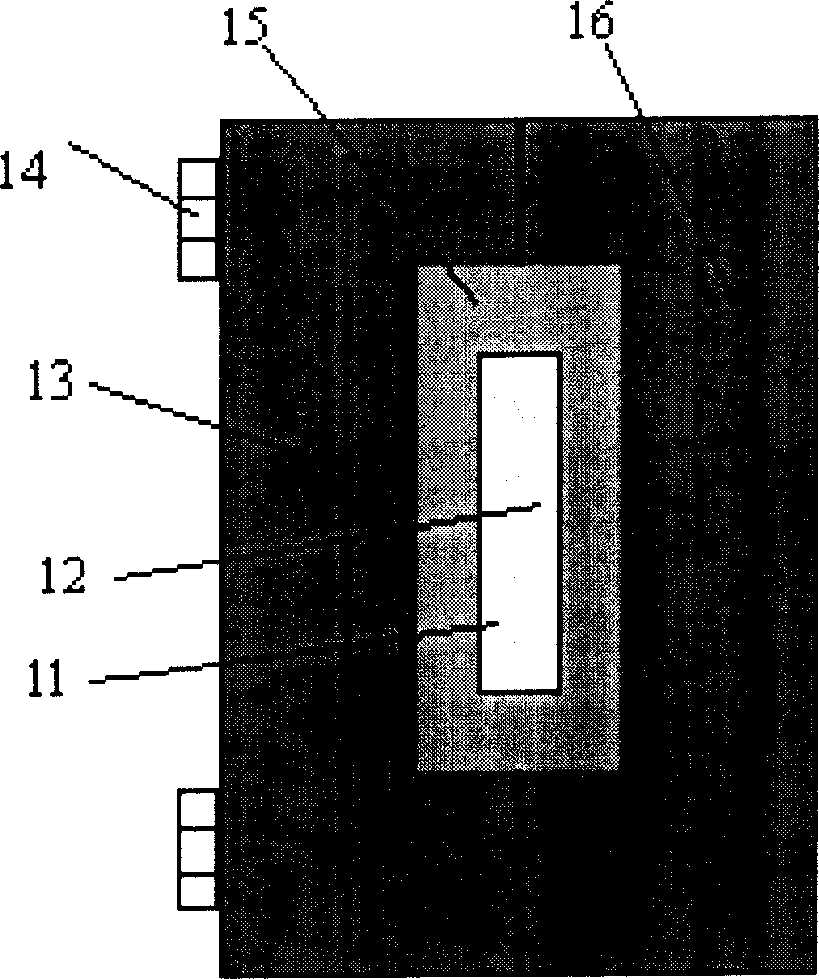

[0017] see figure 1 , the nano-pitch template of the present invention includes two alternately deposited multi-layer Si 3 N 4 Silicon wafers (11, 12) of film and Cr film, left and right clamping blocks (13, 16) for clamping silicon wafers and screws (14) connecting left and right clamping blocks (13, 16), And the epoxy resin (15) that solidifies in the groove of left and right clamping block (13,16) is formed.

[0018] The preparation method of the present invention is as follows:

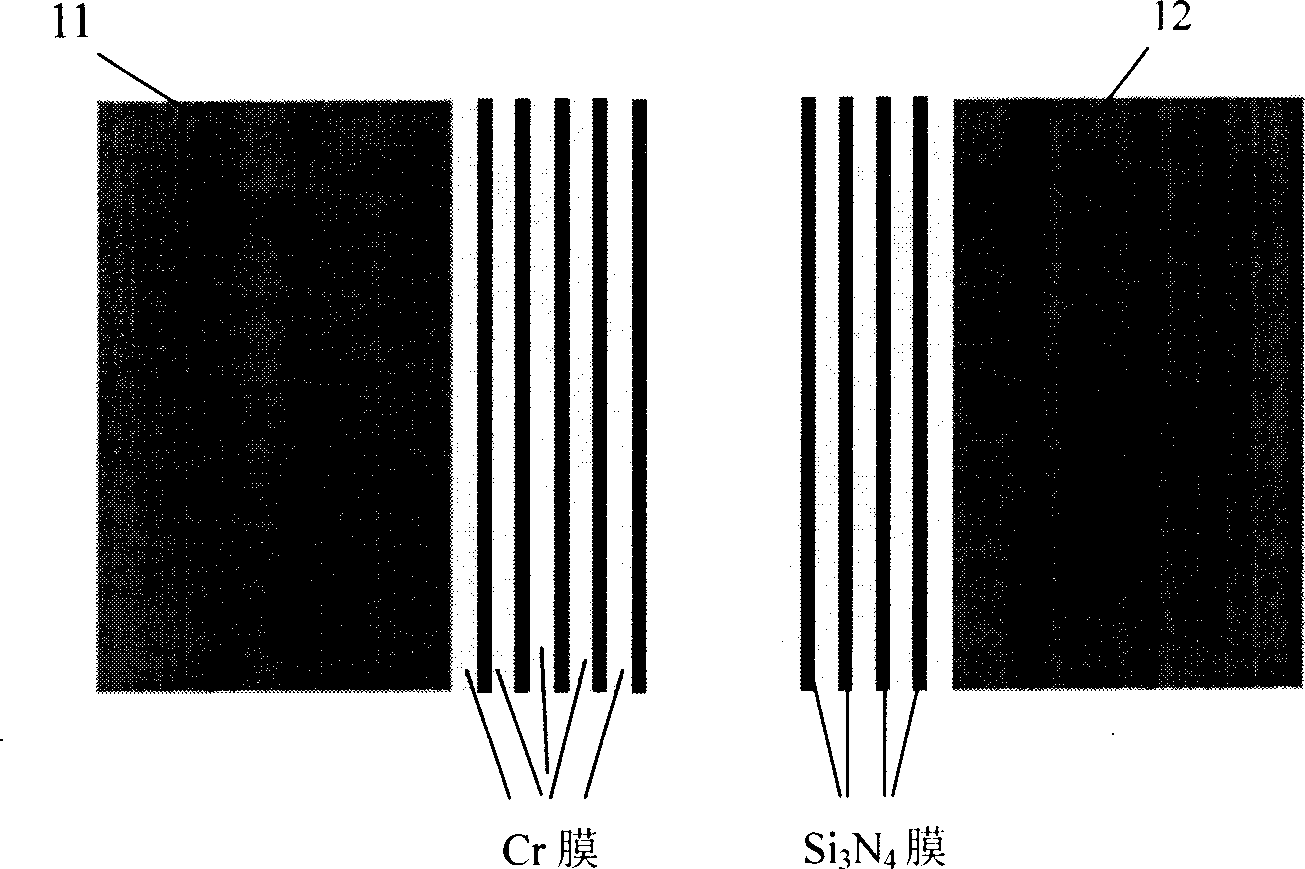

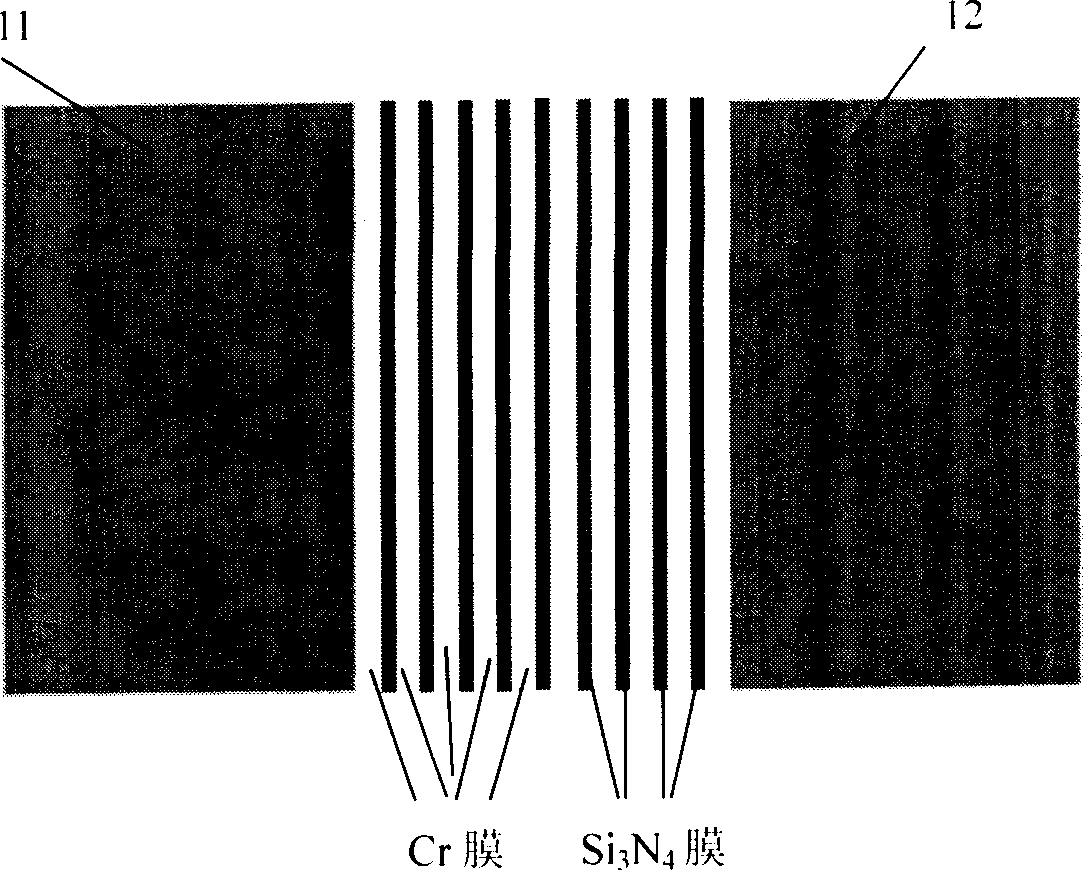

[0019] see figure 2 , image 3 , 1) The silicon chip is immersed in toluene, acetone, deionized water successively and ultrasonically cleaned for 10 minutes. After each ultrasonic cleaning, it is repeatedly cleaned with a large amount of deionized water, and finally dried with nitrogen; then the silicon chip is put into the Piranha solution for 80 Treat at ℃ for 60 minutes, take it out, rinse it fully with a large amount of deionized water, and dry it with high-purity nitrogen; the Piranha s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com