Method for preparing super-hard, high efficacy heat conduction and low-absorption AlxSiyN film by double-target radio frequency magnetron co-sputtering

A radio frequency magnetron, co-sputtering technology, used in sputtering coating, ion implantation coating, metal material coating process and other directions, can solve the problems of large light absorption, poor thermal conductivity, limited application and so on

Inactive Publication Date: 2010-11-10

CHANGCHUN UNIV OF SCI & TECH

View PDF8 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Traditionally known in this field, the shortcomings of similar films are low hardness, poor thermal conductivity, large light absorption and other shortcomings, which limit the application in related fields

Method used

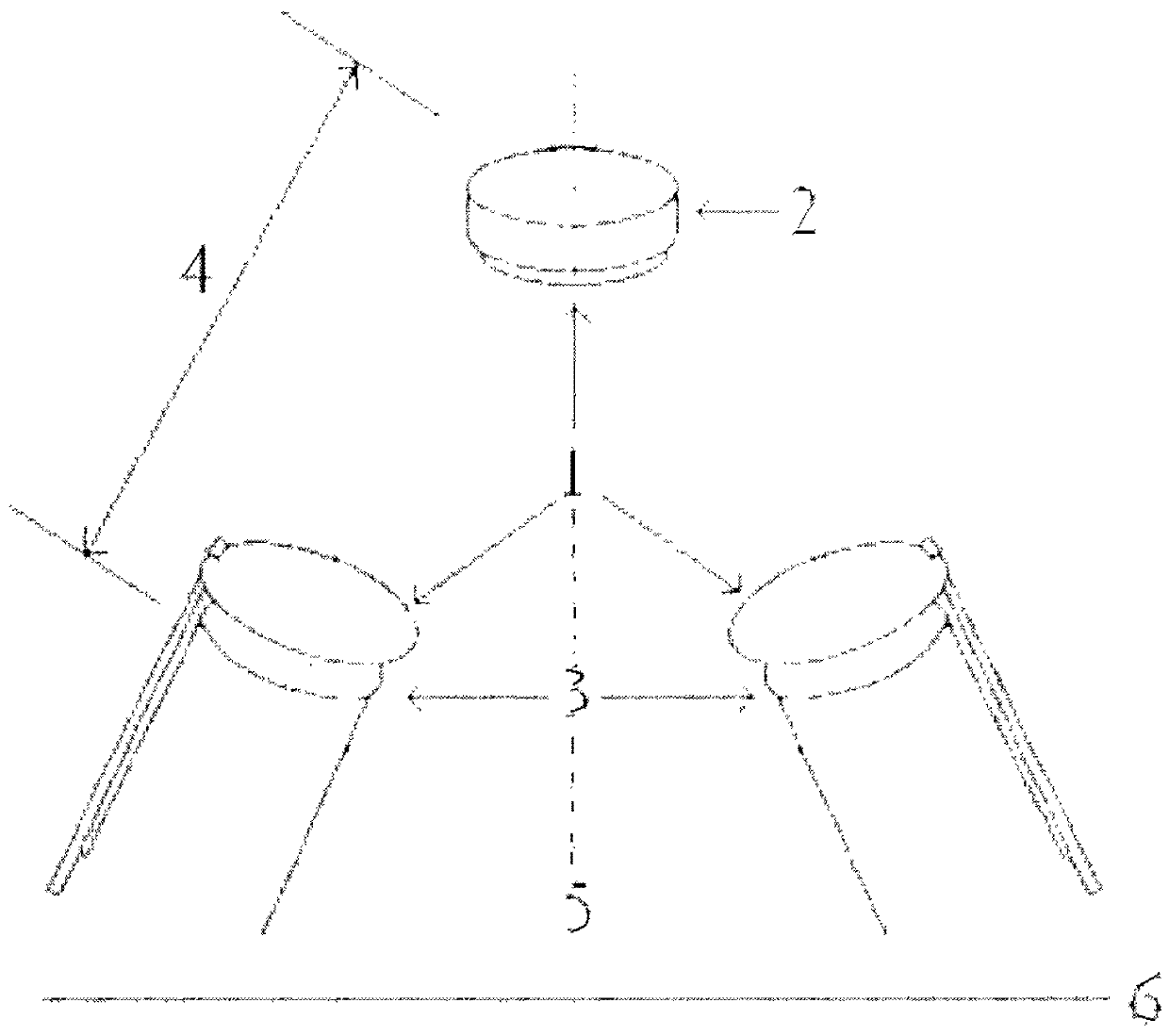

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for preparing a super-hard, high efficacy heat conduction and low-absorption AlxSiyN film by double-target radio frequency magnetron co-sputtering, which belongs to the technical field of thin films. The known thin films of the same type in the field have the defects of low hardness, poor heat conductivity and high light absorption and are limited to be applied in related fields. The method for preparing the super-hard, high efficacy heat conduction and low-absorption AlxSiyN film by the double-target radio frequency magnetron co-sputtering comprises the following steps of: co-sputtering a silicon target and an aluminum target in a proper proportion of nitrogen gas to argon gas under the condition with certain sputtering power ratio between the double targets to form the AlxSiyN film by using a principle of the double-target radio frequency magnetron co-sputtering; and adjusting the gas proportion, the sputtering chamber pressure and the power ratio between the double targets to realize a proper proportion of x to y so as to prepare the super-hard and high efficacy heat conduction antireflection film. The method is of great significance to the promotion of the development in related fields.

Description

A method for double-target radio frequency magnetron co-sputtering of superhard, high-efficiency thermal conductivity, and low-absorption AlxSiyN film technical field The invention relates to the technical fields of optoelectronic materials and thin films. Background technique Traditionally known in this field, the shortcomings of similar films are low hardness, poor thermal conductivity, and large light absorption, which limit the application in related fields. A double-target RF magnetron co-sputtering method for superhard, high-efficiency thermal conductivity, and low-absorption films is to introduce a dual-target co-sputtering mode on the basis of the traditional magnetron sputtering method for magnetron sputtering thin films. A thin film with high hardness, good thermal conductivity and small absorption is deposited on it. Aiming at the shortcomings of traditional thin films, the present invention proposes a double-target radio-frequency magnetron co-sputtering meth...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C14/35C23C14/06

Inventor 乔忠良薄报学高欣张斯玉徐扬张秀曲轶芦鹏李辉李占国刘国军

Owner CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com