Zirconium adulterated lithium manganate anode film material and its making method

A technology of lithium zirconium manganese oxide and cathode thin film, which is applied in the field of all-solid-state thin-film lithium battery cathode material and its preparation, and can solve the problems of expensive cobalt, easy phase transition, and unfavorable practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

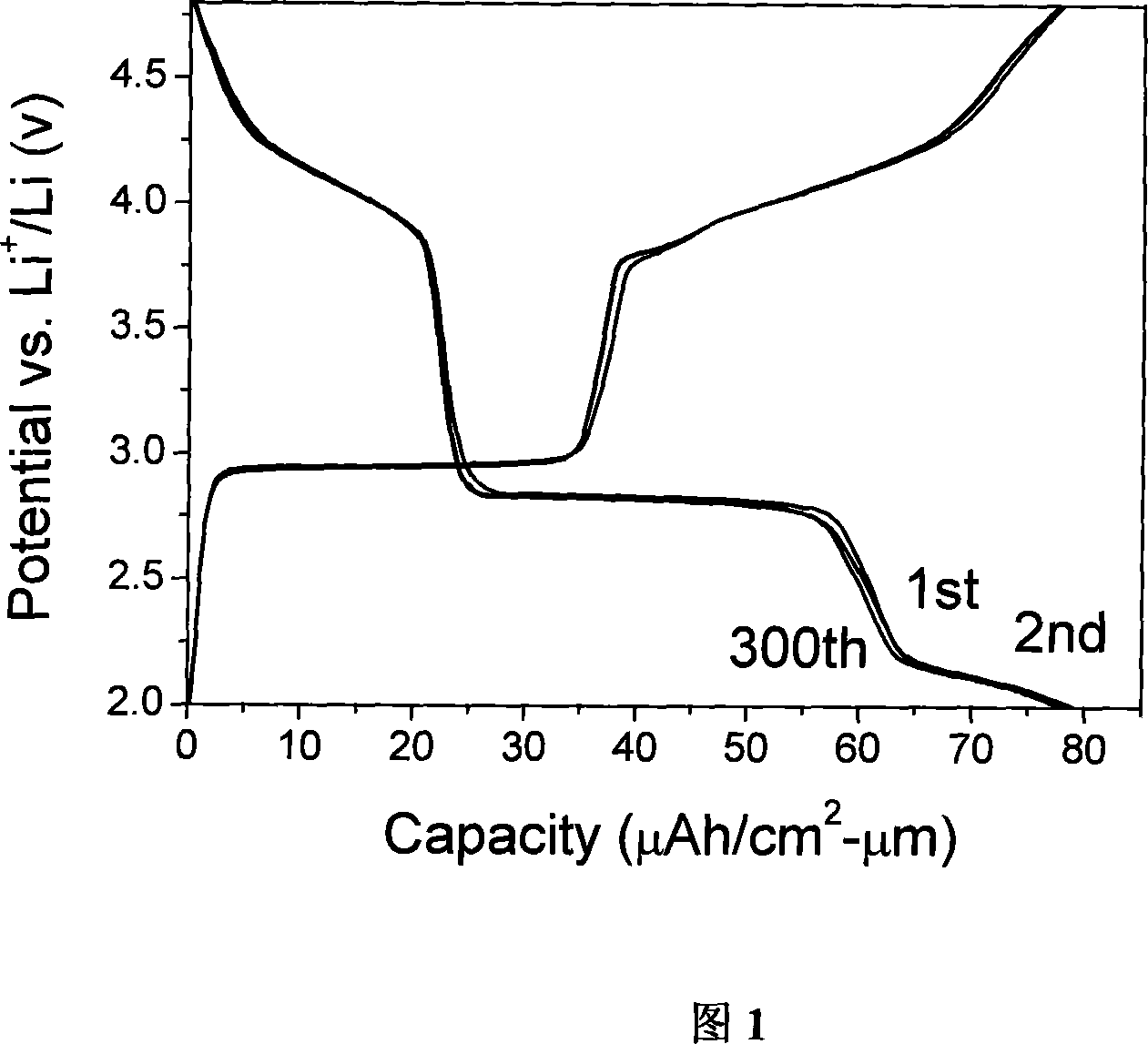

Embodiment 1

[0014] Pure lithium manganese oxide (LMO) cathode thin films were prepared by radio frequency magnetron sputtering deposition method. First, use a molecular pump to pump the air pressure of the vacuum chamber to 1.0×10 -3 Pa, then the flow ratio of the argon gas and oxygen gas that is passed into the vacuum chamber is controlled by two needle valves to be 3:1, the direction of the inlet is facing the deposition substrate, and the flow rate of the mixed gas is adjusted to keep the pressure of the vacuum chamber at 1.0Pa; , the RF output power was 35 watts, the distance between the substrate and the lithium manganese oxide target was 5 cm, the deposition rate was 25 nm per hour, and the substrate temperature was room temperature. In the experiment, a Pt sheet was used as the substrate, and the lithium manganate target was synthesized by a high-temperature solid-state reaction.

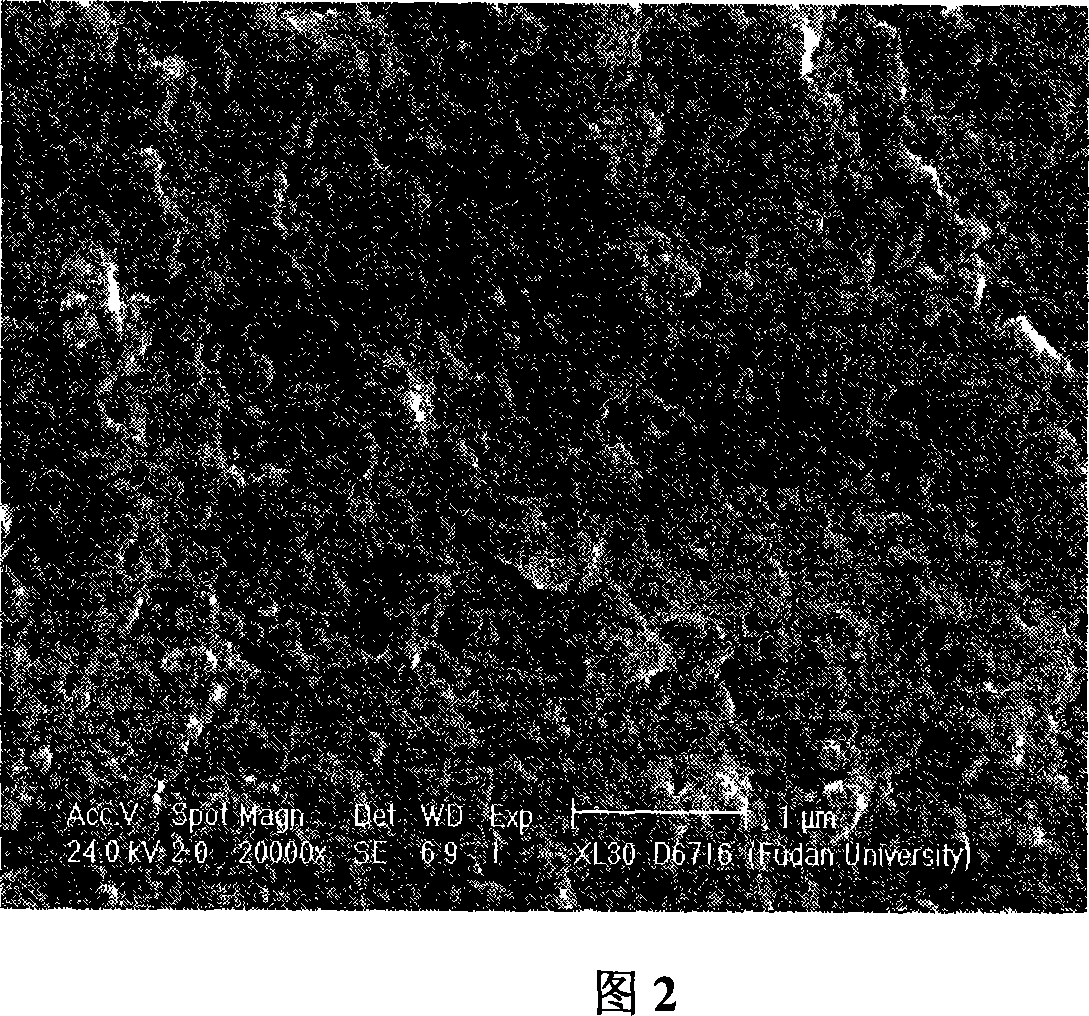

[0015] As determined by X-ray diffraction, the deposited film has a spinel structure. The scanning ...

Embodiment 2

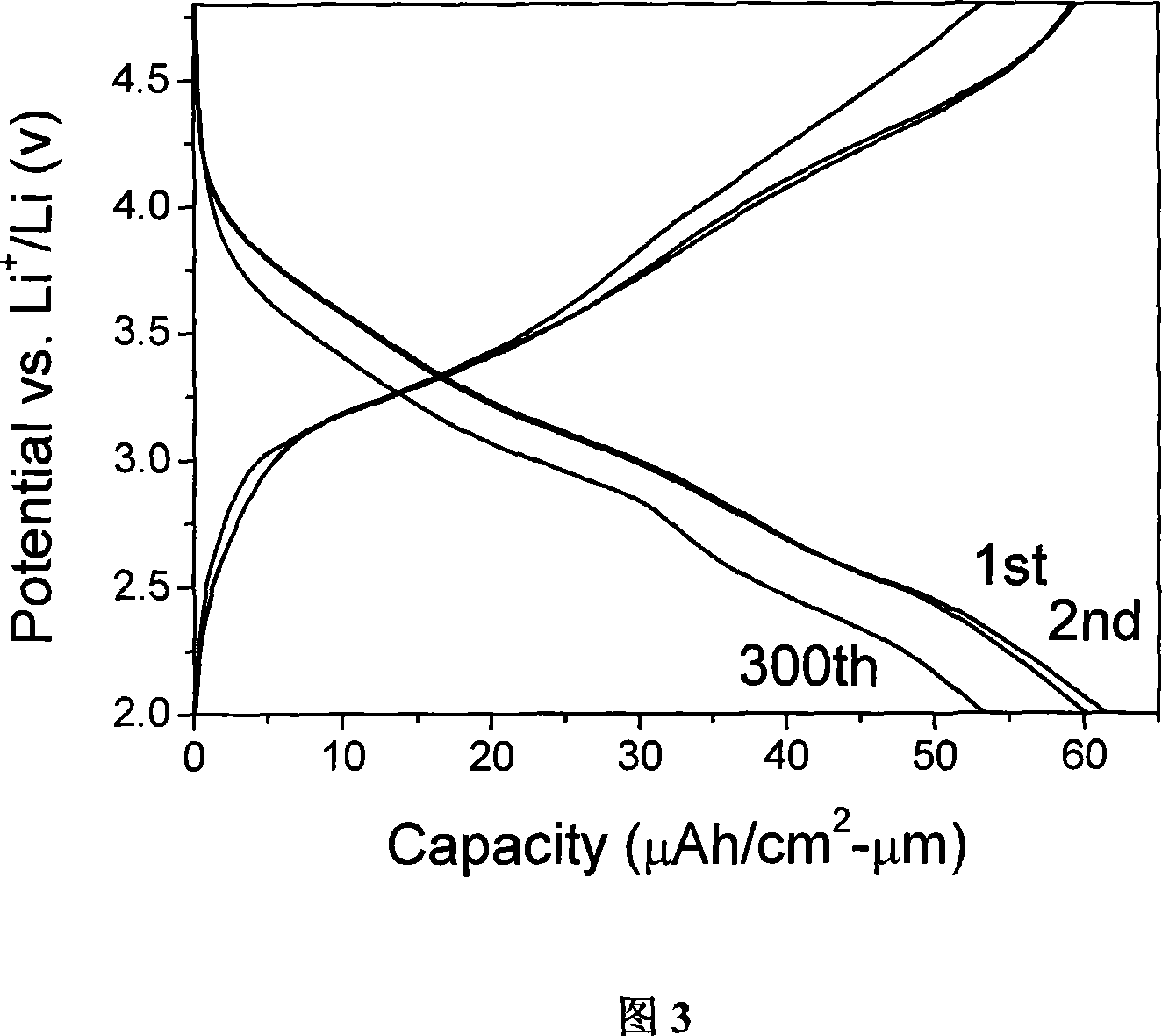

[0018] In the present invention, a radio frequency magnetron sputtering deposition method is used to prepare a lithium zirconium manganese oxide (LMZO) anode thin film. It was carried out in a vacuum system for magnetron sputtering deposition. First, use a molecular pump to pump the air pressure of the vacuum chamber to 1.0×10 -3 Pa, then the volumetric flow rate of argon gas and oxygen gas that is passed into the vacuum chamber is controlled by a needle valve, the flow ratio of argon gas and oxygen gas is 2:1, the direction of the inlet is facing the deposition substrate, and the mixed gas flow rate is adjusted to make the air pressure of the vacuum chamber Keep it at 1.0Pa; during deposition, the RF output power is 40 watts, the distance between the substrate and the zirconium-doped lithium manganese oxide target is 5 cm, the deposition rate is 40 nm per hour, the substrate temperature is room temperature, and the deposited film is heated at 500 ° C in air Annealed for 2 ho...

Embodiment 3

[0022] In the present invention, a radio frequency magnetron sputtering deposition method is used to prepare a lithium zirconium manganese oxide (LMZO) anode thin film. It was carried out in a vacuum system for magnetron sputtering deposition. First, use a molecular pump to pump the air pressure of the vacuum chamber to 1.0×10 -3 Pa, then the volume flow rate of argon gas and oxygen gas that is passed into the vacuum chamber is controlled by a needle valve, the flow ratio of argon gas and oxygen gas is 3:1, the direction of the inlet is facing the deposition substrate, and the mixed gas flow rate is adjusted so that the air pressure of the vacuum chamber Keep it at 1.2Pa; during deposition, the RF output power is 40 watts, the distance between the substrate and the zirconium-doped lithium manganese oxide target is 5 cm, the deposition rate is 35 nm per hour, the substrate temperature is room temperature, and the deposited film is heated at 500 ° C in air Annealed for 2 hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com