Magnetic-phase-oriented barium titanate/Ni-Zn ferrite nanocrystalline complex-phase thin film and preparation method thereof

A technology of nickel-zinc ferrite and barium titanate is applied in the field of composite film and its preparation, barium titanate/nickel-zinc ferrite nanocrystalline composite film material and preparation field, and can solve the complex preparation method, magnetoelectric The problems of weak coupling and high dielectric loss can achieve the effect of simple preparation process, high electromagnetic coupling effect and high magnetic loss performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

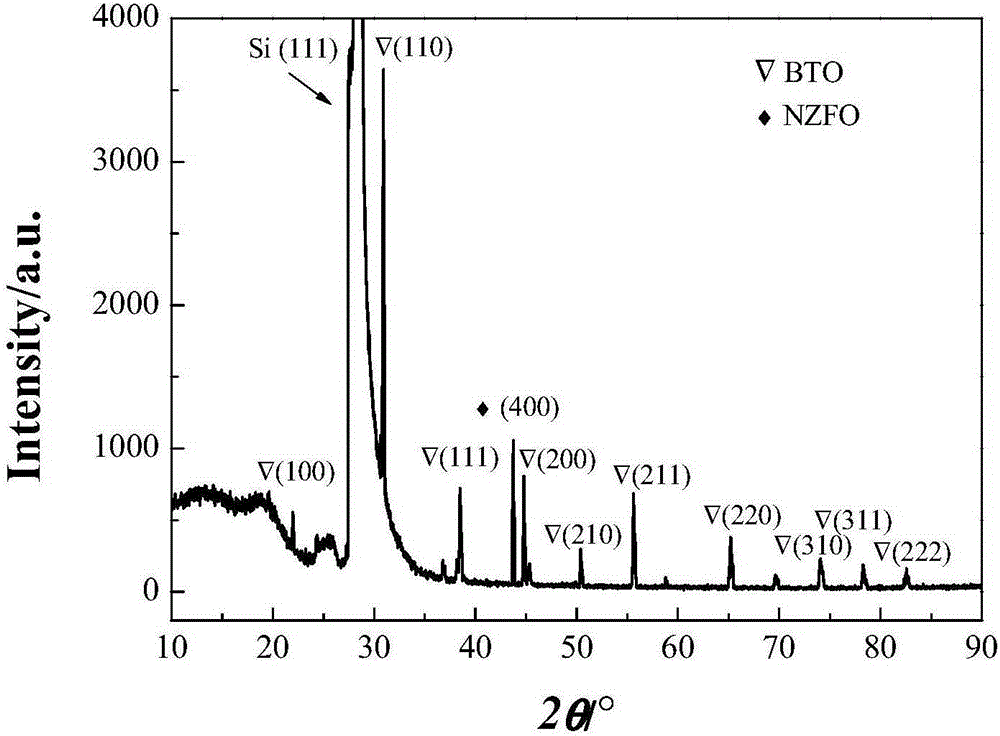

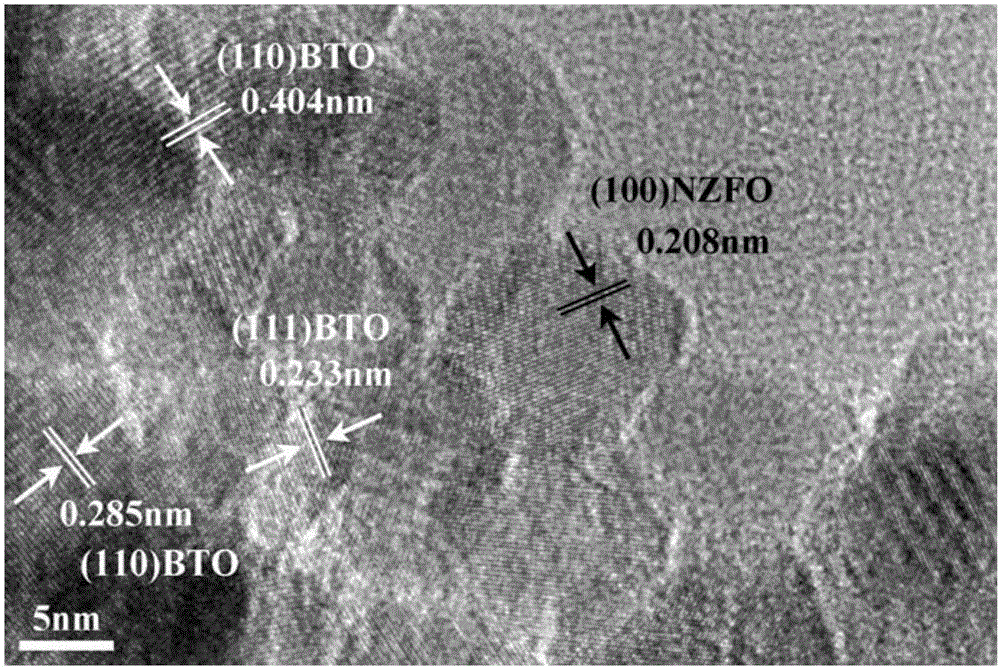

Embodiment 1

[0034] 1) After the (111) oriented monocrystalline silicon is preliminarily cleaned with deionized water, soak it in hydrofluoric acid for 5 minutes, and then place it in ethanol for ultrasonic cleaning for 10 minutes; place the cleaned monocrystalline silicon wafer in vacuum drying Dry in an oven to obtain a sputtered substrate.

[0035] 2) Put the complex phase sputtering target made of barium titanate and iron zinc ferrite at a molar ratio of 0.6:0.4 and the cleaned (111) single crystal silicon sputtering substrate in the radio frequency magnetron sputtering apparatus In the sputtering chamber; vacuumize the sputtering chamber and then pass a mixed gas of oxygen and argon with an oxygen partial pressure of 0.4 as the sputtering atmosphere; control the total pressure of the mixed gas at 8×10 -4 After mbar, the RF power was adjusted to 200W, and a uniform and dense amorphous film was obtained by sputtering deposition at room temperature for 4h.

[0036] 3) Place the uniform ...

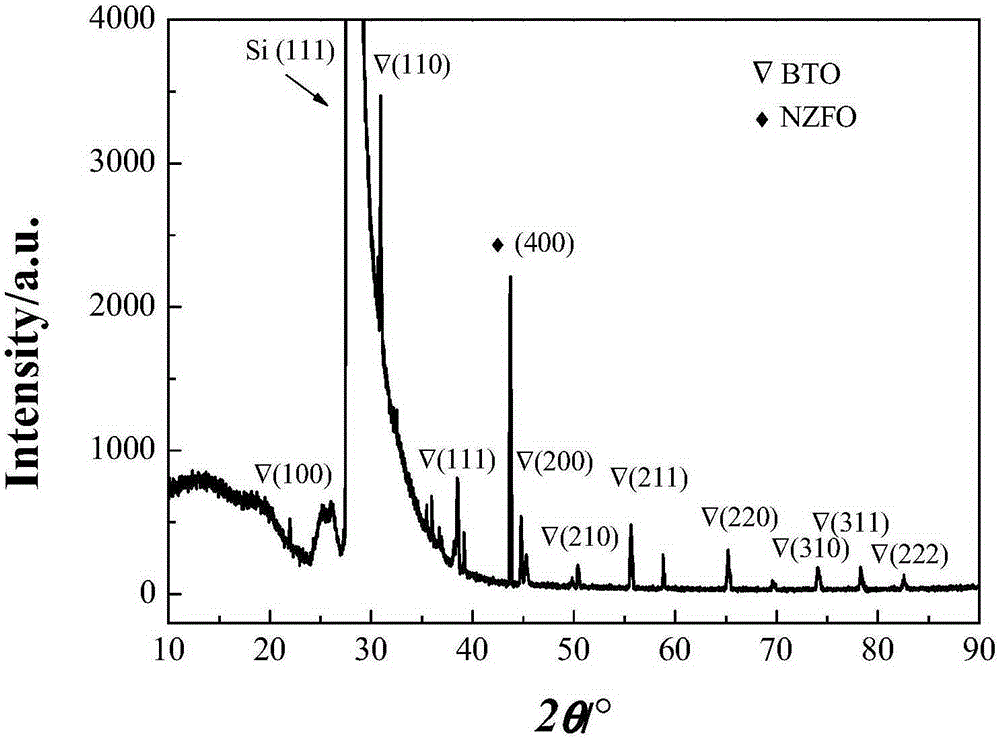

Embodiment 2

[0039] 1) After the (111) oriented monocrystalline silicon is preliminarily cleaned with deionized water, soak in hydrofluoric acid for 4 minutes, and then placed in ethanol for ultrasonic cleaning for 15 minutes; place the cleaned monocrystalline silicon wafer in vacuum drying Dry in an oven to obtain a sputtered substrate.

[0040] 2) Put the complex phase sputtering target made of barium titanate and iron zinc ferrite at a molar ratio of 0.4:0.6 and the cleaned (111) single crystal silicon sputtering substrate in the radio frequency magnetron sputtering apparatus In the sputtering chamber; vacuumize the sputtering chamber and then pass a mixed gas of oxygen and argon with an oxygen partial pressure of 0.5 as the sputtering atmosphere; control the total pressure of the mixed gas at 2×10 -3 After mbar, the RF power was adjusted to 220W, and a uniform and dense amorphous film was obtained by sputtering deposition at room temperature for 2h.

[0041] 3) The uniform and dense a...

Embodiment 3

[0044] 1) After the (111) oriented single crystal silicon was preliminarily cleaned with deionized water, soaked in hydrofluoric acid for 6 minutes, and then placed in ethanol for ultrasonic cleaning for 10 minutes; the cleaned single crystal silicon wafer was placed in vacuum drying Dry in an oven to obtain a sputtered substrate.

[0045] 2) The complex phase sputtering target obtained by barium titanate iron zinc ferrite with a molar ratio of 0.1:0.9 and the cleaned (111) single crystal silicon sputtering substrate are placed in a radio frequency magnetron sputtering apparatus for sputtering chamber; after vacuuming the sputtering chamber, a mixture of oxygen and argon with an oxygen partial pressure of 0.3 is used as the sputtering atmosphere; the total pressure of the mixture is controlled at 0.6×10 -3 After mbar, the RF power was adjusted to 160W, and a uniform and dense amorphous film was obtained by sputtering deposition at room temperature for 6h.

[0046] 3) The unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com