Method sputtering tin target and copper sulfide target to prepare copper-tin-sulfur film and battery

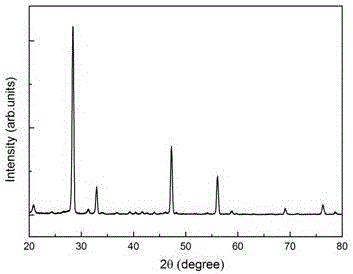

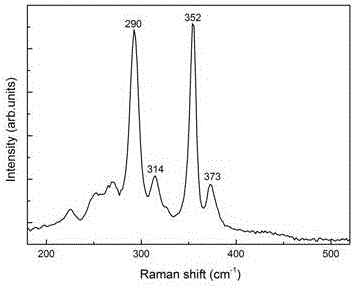

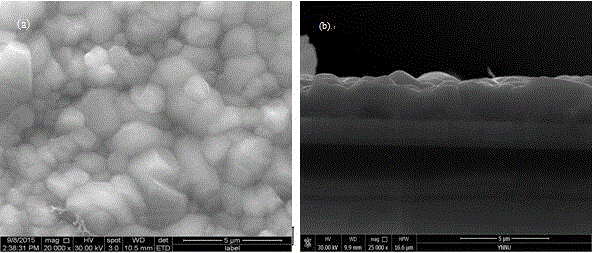

A technology of copper tin sulfur and copper sulfide, which is used in sputtering plating, circuits, photovoltaic power generation and other directions to achieve the effect of good crystal quality, large grain size and dense surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The operation steps are as follows:

[0021] 1. Put the soda-lime glass or molybdenum-coated soda-lime glass substrate in the vacuum chamber of the magnetron sputtering film, and pump the chamber to the back vacuum of 5×10 -4 Pa;

[0022] 2. Adjust the rotation speed of the substrate table to 7 rpm, sputter a tin metal layer on the substrate with a radio frequency sputtering power of 50W, then sputter copper sulfide with a radio frequency sputtering power of 100W, and use Sn / CuS Sequential sputtering three cycles to prepare a copper-tin-sulfur thin film prefabricated layer with a thickness of about 800nm, and the substrate is not heated;

[0023] 3. Place the prefabricated layer of the copper-tin-sulfur film in the annealing furnace, pump the annealing furnace to a low vacuum and then flush nitrogen as a protective gas until the pressure in the annealing furnace reaches 3000Pa to perform soft annealing on the prefabricated layer. At a heating rate of 35°C / min, heat fr...

Embodiment 2

[0027] The operation steps are as follows:

[0028] 1. Put the soda-lime glass or molybdenum-coated soda-lime glass substrate in the vacuum chamber of the magnetron sputtering film, and pump the chamber to the back vacuum of 5×10 -4 Pa;

[0029] 2. Adjust the rotation speed of the substrate table to 7 rpm, sputter a tin metal layer on the substrate with a radio frequency sputtering power of 50W, then sputter copper sulfide with a radio frequency sputtering power of 100W, and use Sn / CuS Sequential sputtering three cycles to prepare a copper-tin-sulfur thin film prefabricated layer with a thickness of about 800nm, and the substrate is not heated;

[0030] 3. Place the prefabricated layer of the copper-tin-sulfur film in the annealing furnace, pump the annealing furnace to a low vacuum and then flush nitrogen as a protective gas until the pressure in the annealing furnace reaches 3000Pa to perform soft annealing on the prefabricated layer. At a heating rate of 30°C / min, heat fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com