Multi-resistance-state double-layer film resistance random access memory and manufacturing method therefor

A double-layer thin-film, multi-resistance state technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that the preparation method of resistive memory has not been reported, achieve stable retention characteristics and cycle characteristics, and be widely used Effect of foreground, large memory window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

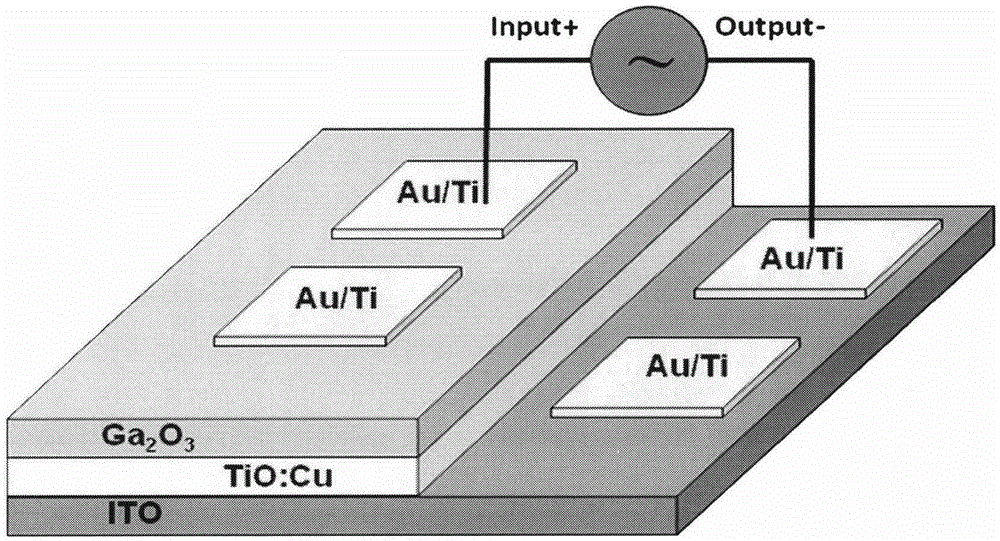

[0029] Further illustrate the implementation steps of the present invention below by specific example:

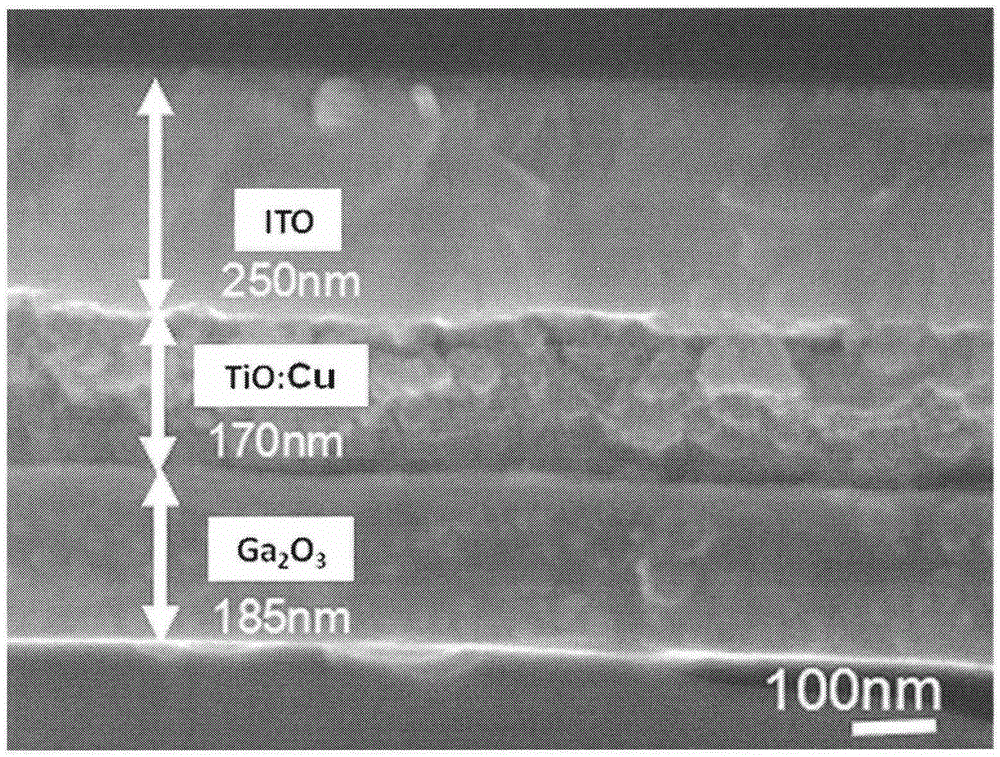

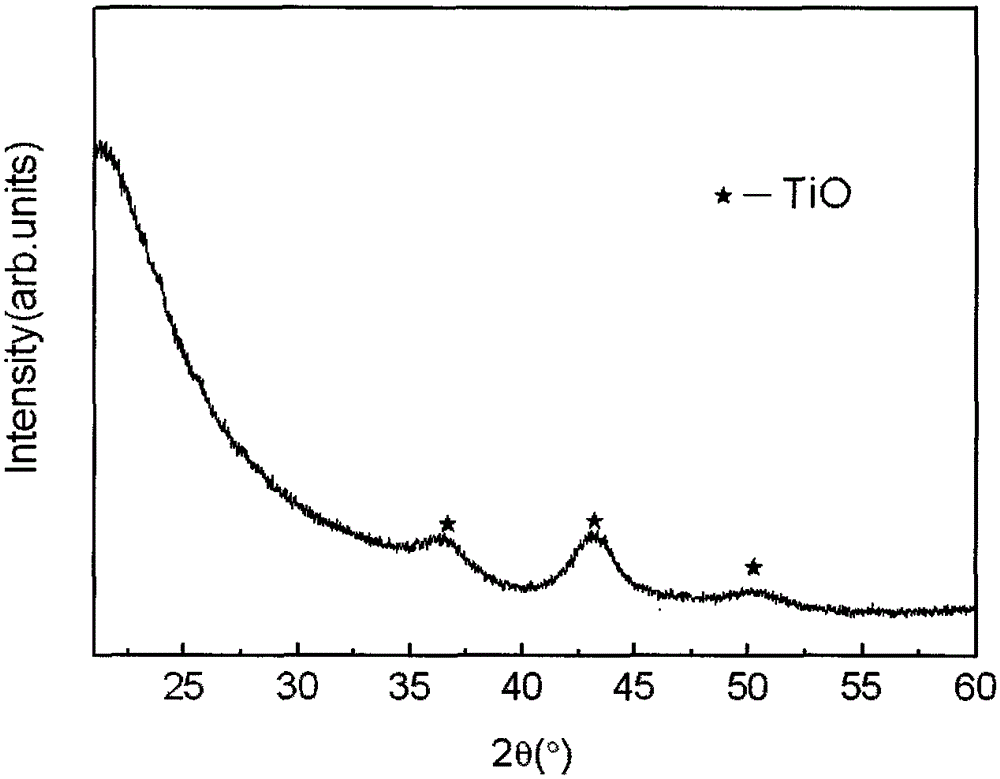

[0030] Take a piece of ITO substrate, ultrasonically clean it in deionized water, acetone, deionized water, ethanol, deionized water for 5min, 15min, 5min, 15min, 5min, and dry naturally. The cleaned substrate was placed in the vacuum chamber of radio frequency magnetron sputtering, using Cu target (99.9%) and TiO 2 Target (99.9%) TiO:Cu films were deposited by co-sputtering with two targets. The chamber vacuum before sputtering is 1.6×10 -5 pa, the chamber pressure during sputtering is 1.0Pa, the argon gas flow in the chamber is 25sccm, the film deposition temperature is 300K at room temperature, the sputtering power of Cu target is 25W, TiO 2 The target sputtering power was 150W, and the total sputtering time was 1.0 hour. The resulting TiO:Cu film was vacuum annealed to a vacuum degree of 1.6×10 -5 pa, the annealing temperature is 573K, and the annealing time is 1 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com