Preparation method of electrolyte thin film for all-solid-state thin-film lithium ion battery

An electrolyte film and lithium-ion battery technology, applied in the field of electrolyte film preparation, can solve problems such as restricting the development of all-solid-state thin-film lithium-ion batteries, and achieve the effects of good thermodynamic stability, small size and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present invention relates to a kind of preparation method of electrolyte film for all-solid-state thin-film lithium-ion battery, and it comprises the following steps of carrying out successively:

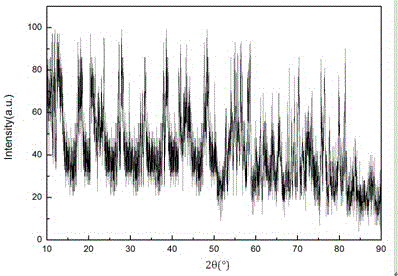

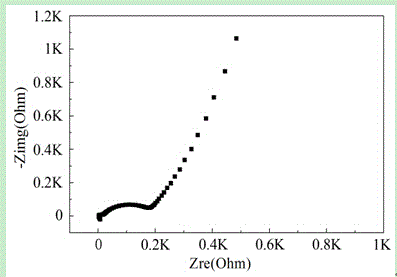

[0023] ①, using radio frequency magnetron sputtering method, using Li 3 PO 4 The target requires a relative density greater than 99%, a purity greater than 99.9%, a diameter of 60mm, and a thickness of 6mm; after the target and substrate are installed, close the sputtering chamber and evacuate the sputtering chamber to 1.0×10 -4 Pa, filled with a mixed gas of helium and hydrogen at 1 atmospheric pressure (in the mixed gas, the volume ratio of helium to hydrogen is 0.2:1), and then the indoor gas pressure is pumped to 1.2Pa;

[0024] ② Pre-sputtering to clean the oxide layer and impurities on the target surface;

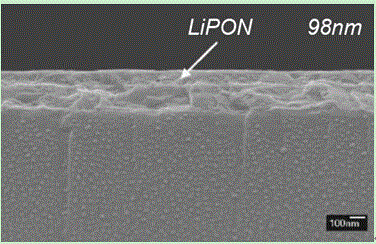

[0025] ③. Set the sputtering power to 3W / cm 2 , the distance between the target and the base is 60 mm, and the sputtering time is 4 ho...

Embodiment 2

[0033] The invention relates to a method for preparing an electrolyte film for an all-solid-state thin-film lithium-ion battery. The specific preparation process is as follows:

[0034] ①, using radio frequency magnetron sputtering method, using Li 3 PO 4 The target requires a relative density greater than 99%, a purity greater than 99.9%, a diameter of 60mm, and a thickness of 6mm; after the target and substrate are installed, close the sputtering chamber and evacuate the sputtering chamber to 1.0×10 -4 Pa, filled with a mixed gas of helium and hydrogen at 1 atmospheric pressure (in the mixed gas, the volume ratio of helium to hydrogen is 0.8:1), and then the indoor gas pressure is pumped to 1.5Pa;

[0035] ② Pre-sputtering to clean the oxide layer and impurities on the target surface;

[0036] ③. Set the sputtering power to 4W / cm 2 , the distance between the target and the base is 60 mm, and the sputtering time is 5 hours to form a LiPON thin film;...

Embodiment 3

[0040] The invention relates to a method for preparing an electrolyte film for an all-solid-state thin-film lithium-ion battery. The specific preparation process is as follows:

[0041] ①, using radio frequency magnetron sputtering method, using Li 3 PO 4 The target requires a relative density greater than 99%, a purity greater than 99.9%, a diameter of 60mm, and a thickness of 6mm; after the target and substrate are installed, close the sputtering chamber and evacuate the sputtering chamber to 1.0×10 -4 Pa, filled with a mixed gas of helium and hydrogen at 1 atmospheric pressure (in the mixed gas, the volume ratio of helium to hydrogen is 0.3:1), and then pump the indoor gas pressure to 2Pa;

[0042] ② Pre-sputtering to clean the oxide layer and impurities on the target surface;

[0043] ③. Set the sputtering power to 5W / cm 2 , the target base distance is 60mm, and the sputtering time is 6 hours to form a LiPON thin film;

[0044] ④. Turn off the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com