Manufacturing method of mica paper for capacitor

A manufacturing method and technology of mica paper, applied in the direction of special paper, papermaking, paper, etc., can solve the problems of unusable production volume and low dielectric strength, achieve small size, good quality, improve electrical performance and tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

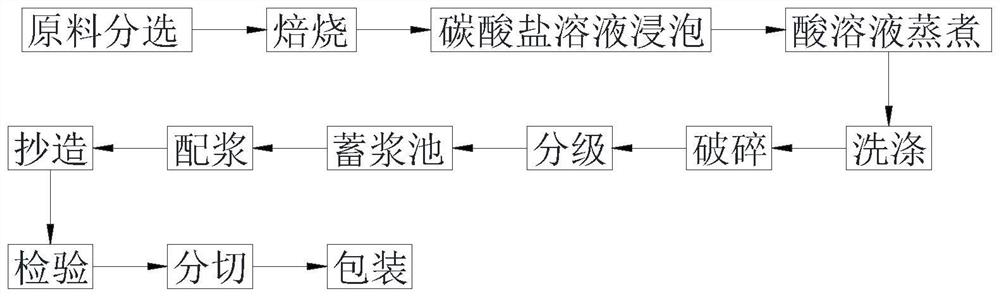

[0027] see figure 1 , a kind of manufacture method of mica paper for capacitor, comprises the steps:

[0028] a. Raw material sorting: select high-quality mica raw materials;

[0029] b. Roasting: put the mica raw material into the roasting furnace for roasting, the roasting temperature is 750-850°C, the roasting time is 40-50min, and then cooled to room temperature;

[0030] c, chemical cooking: first prepare a carbonate solution with a mass concentration of 1%, add the mica raw material roasted in step b, soak in the carbonate solution for 10 to 15 minutes, and then soak the mica in the carbonate solution Put the raw materials into an acid solution with a mass concentration of 3-5%, heat to boiling and cook for 30 minutes;

[0031] d. Washing: filter out the raw materials cooked in the acidic solution, and wash with clear water until the raw material washing water is neutral;

[0032] e. Pulping: the washed raw materials are crushed and filtered to prepare a slurry with a...

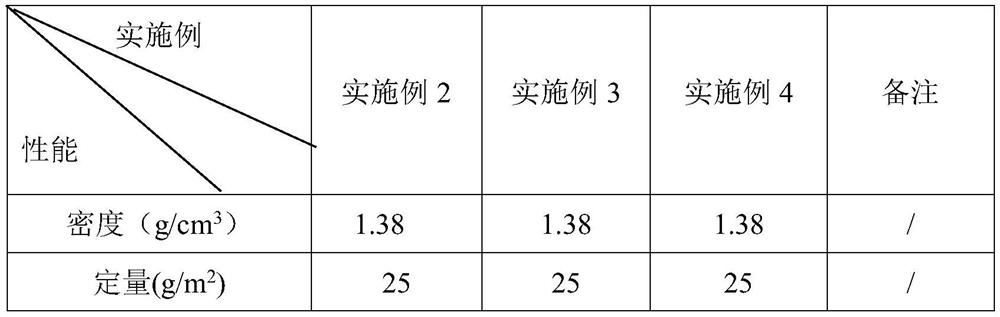

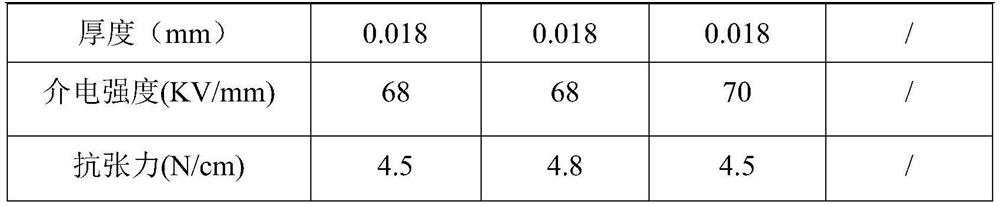

Embodiment 2

[0044] This embodiment adopts artificially selected raw materials, and selects high-quality natural muscovite fragments as raw materials, with an area size of 5 cm 2 About, thickness 1 ~ 2mm. Weathered mica, rusty mica, stained mica, ore and foreign impurities are not allowed in the raw materials, and the quantity is 10kg / bag. After preheating the roasting furnace to 750°C, open the furnace cover and pour in a bag of 10kg of raw materials, close the furnace cover, and pour out after roasting for 40 minutes while the furnace body is rotating. Let cool to room temperature.

[0045] The raw materials after roasting are screened by drum type sieves, the powder is removed, and the mass concentration of carbonate solution is 1% in the alkali tank. The mica raw materials after roasting are first soaked in carbonate solution for 10 minutes, and then The mass concentration of the acid solution in the vat is 3%, put the mica raw material treated with the carbonate solution into the ac...

Embodiment 3

[0048] Using artificially selected raw materials, high-quality natural muscovite fragments are selected as raw materials, with an area of about 5cm2 and a thickness of 1-2mm. Weathered mica, rusty mica, stained mica, ore and foreign impurities are not allowed in the raw materials, and the quantity is 10kg / bag. After preheating the roasting furnace to 800°C, open the furnace cover and pour in a pack of 10kg raw materials and close the furnace cover, pour out after 45 minutes of roasting time under the rotating state of the furnace body, and cool to room temperature;

[0049] The roasted raw materials are screened through a drum sieve to remove the powder, and a carbonate solution with a mass concentration of 1% is prepared in an alkali vat. The roasted mica raw material is first soaked in a carbonate solution for 12 minutes, and then placed in an acid vat. The mass concentration of the internal acid solution is 4%, put the mica raw material treated with the carbonate solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com