Mobile phone liquid crystal screen vertical edging surface adsorption device and using method thereof

A technology of mobile phone liquid crystal and adsorption device, which is applied to grinding driving device, grinding automatic control device, grinding machine, etc., can solve the problems of increasing the occupied space, increasing the moving stroke, and large size of the grinding machine, so as to save the use space. , the use of small space, the effect of small production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

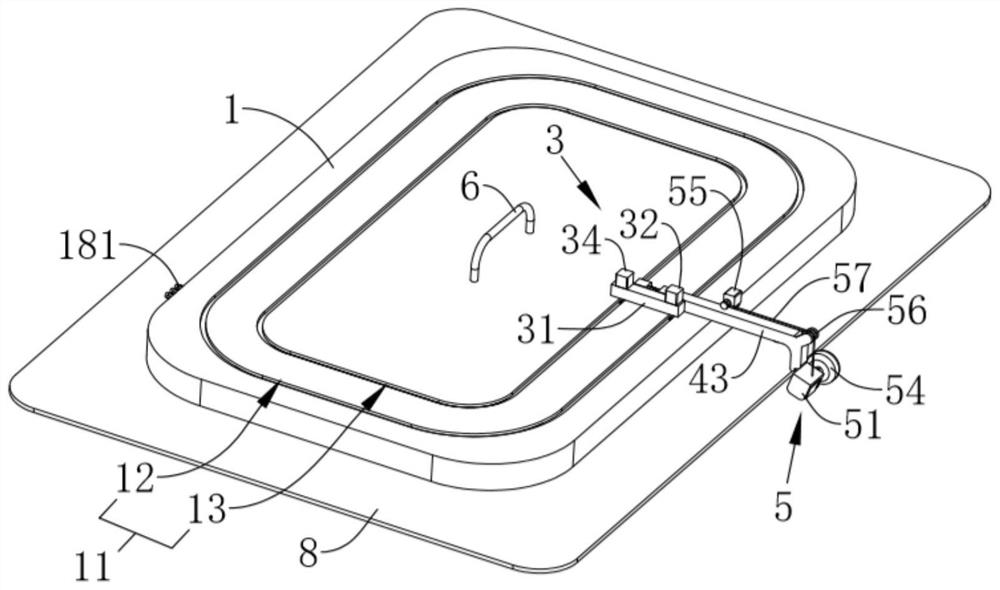

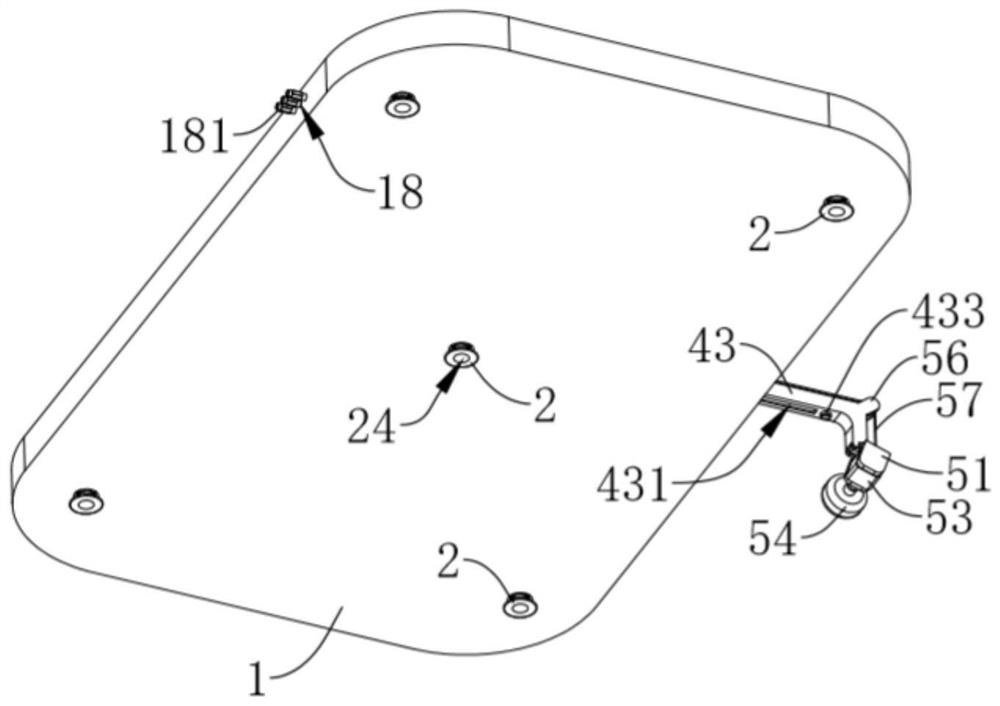

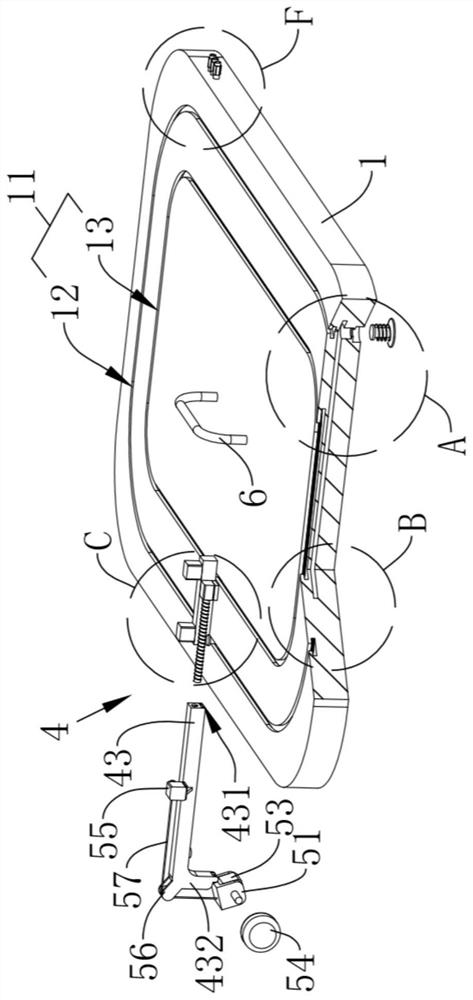

[0035] refer to Figure 1 to Figure 3 ,as well as Figure 9 As shown, a mobile phone liquid crystal screen vertical grinding surface adsorption device, including a support plate 1, the plane of the support plate 1 is waist-like setting, the plane of the support plate 1 is provided with a number of working holes 14, the working holes 14 are connected with suction cups 2, The suction surface of the suction cup 2 is provided with a negative pressure hole 24 connected with the working hole 14, and the side of the support plate 1 is provided with an air extraction hole 18, and the air extraction holes 18 are all connected with several working holes 14, and the support plate 1 is far away from the end surface of the suction cup 2 An annular groove group 11 is provided, and the annular groove group 11 is provided with a base 31, and a driving member 3 for driving the base 31 to move along the contour direction of the annular groove group 11 is arranged between the base 31 and the ann...

Embodiment 2

[0052] The difference between embodiment 2 and embodiment 1 is:

[0053] refer to Figure 13 As shown, when the display screen 8 of the mobile phone is large and other tools need to be assisted to operate, the end face of the support plate 1 away from the suction cup 2 is detachably connected with a mechanical arm, and the mechanical arm is equipped with a robot 7 supported on the ground, so as to realize the use of the robot. 7 The auxiliary support plate 1 makes the suction cup 2 on the support plate 1 and the display screen 8 mutually adsorbed and connected, so as to achieve the function of fixing the display screen 8, and can replace manual operation, which has the beneficial effect of easy operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com