Monolithically-integrated multi-functional ultraviolet/solar blind ultraviolet two-color detector and fabrication method thereof

A dual-color detector, monolithic integration technology, applied in the direction of photometry, ultraviolet measurement, semiconductor devices, etc. using electrical radiation detectors, which can solve the problem of increasing the size of the detector, affecting the convenience, increasing the complexity of the detector and increasing the manufacturing cost and other problems, to achieve the effect of convenient carrying, sensitive response and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

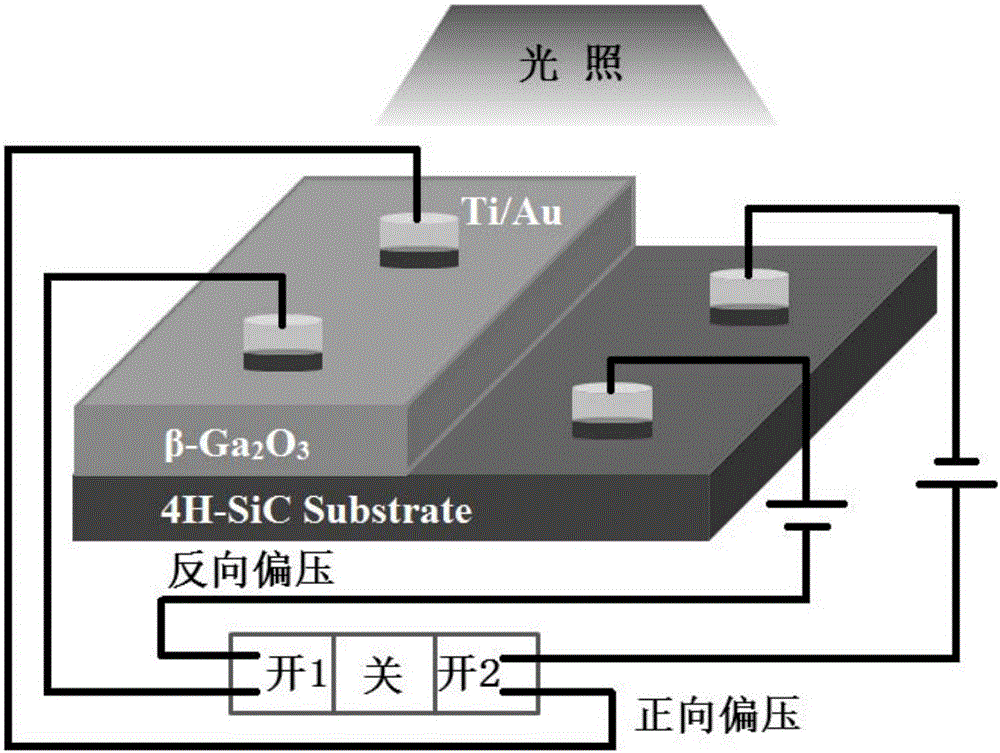

Method used

Image

Examples

Embodiment 1

[0028] Proceed as follows:

[0029] 1) Put the n-type 4H-SiC substrate into V(HF):V(H 2 o 2 )=1:5 solution soaked to remove the natural oxide layer, then ultrasonic cleaning with acetone, ethanol and deionized water respectively, and vacuum drying;

[0030] 2) put Ga 2 o 3 The target is placed on the target stage of the laser molecular beam epitaxy system, and the n-type 4H-SiC substrate processed in step 1) is fixed on the sample holder and put into the vacuum chamber;

[0031] 3) Vacuum the cavity, feed oxygen, adjust the pressure in the vacuum cavity, heat the n-type 4H-SiC substrate, and grow β-Ga 2 o 3 thin film, after the growth of the thin film is completed, continue to feed oxygen, adjust the pressure in the vacuum chamber, and the obtained β-Ga 2 o 3 The thin film is annealed in situ; among them, Ga 2 o 3 The distance between the target and the n-type 4H-SiC substrate was set at 5 cm, and the chamber pressure after vacuuming was 1×10 -6 Pa, when heating the ...

Embodiment 2

[0035] Steps (1), (2) and (4) are all the same as in Example 1. In step (3), the chamber is first evacuated, oxygen is introduced, the pressure in the vacuum chamber is adjusted, and the n-type 4H-SiC substrate is heated to grow β-Ga 2 o 3 thin film, after the growth of the thin film is completed, continue to feed oxygen, adjust the pressure in the vacuum chamber, and the obtained β-Ga 2 o 3 The thin film is annealed in situ; among them, Ga 2 o 3 The distance between the target and the n-type 4H-SiC substrate was set at 5 cm, and the chamber pressure after vacuuming was 1×10 -6 Pa, when heating the n-type 4H-SiC substrate, the cavity pressure is 1×10 -3 Pa, β-Ga 2 o 3 When the film is annealed in situ, the cavity pressure is 1Pa, and the laser energy is 5J / cm 2 , the laser pulse frequency is 1Hz, the laser wavelength is 248nm, the heating temperature of n-type 4H-SiC substrate is 700℃, β-Ga 2 o 3 The annealing temperature of the film is 750° C., and the annealing tim...

Embodiment 3

[0038] Steps (1), (2) and (4) are all the same as in Example 1. In step (3), the chamber is first evacuated, oxygen is introduced, the pressure in the vacuum chamber is adjusted, and the n-type 4H-SiC substrate is heated to grow β-Ga 2 o 3 thin film, after the growth of the thin film is completed, continue to feed oxygen, adjust the pressure in the vacuum chamber, and the obtained β-Ga 2 o 3 The thin film is annealed in situ; among them, Ga 2 o 3 The distance between the target and the n-type 4H-SiC substrate was set at 5 cm, and the chamber pressure after vacuuming was 1×10 -6 Pa, when heating the n-type 4H-SiC substrate, the cavity pressure is 1×10 -3 Pa, β-Ga 2 o 3 When the film is annealed in situ, the cavity pressure is 1.5Pa, and the laser energy is 5J / cm 2 , the laser pulse frequency is 1Hz, the laser wavelength is 248nm, the heating temperature of n-type 4H-SiC substrate is 750℃, β-Ga 2 o 3 The annealing temperature of the film is 750° C., and the annealing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com