Full-non-vacuum process preparation method of copper-zinc-tin-sulfur thin film solar cell

A solar cell, copper-zinc-tin-sulfur technology, applied in the direction of circuits, electrical components, final product manufacturing, etc., can solve the problems of unfavorable large-scale production and high manufacturing cost, achieve good promotion and utilization value, low process cost, and suitable for large-scale production. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

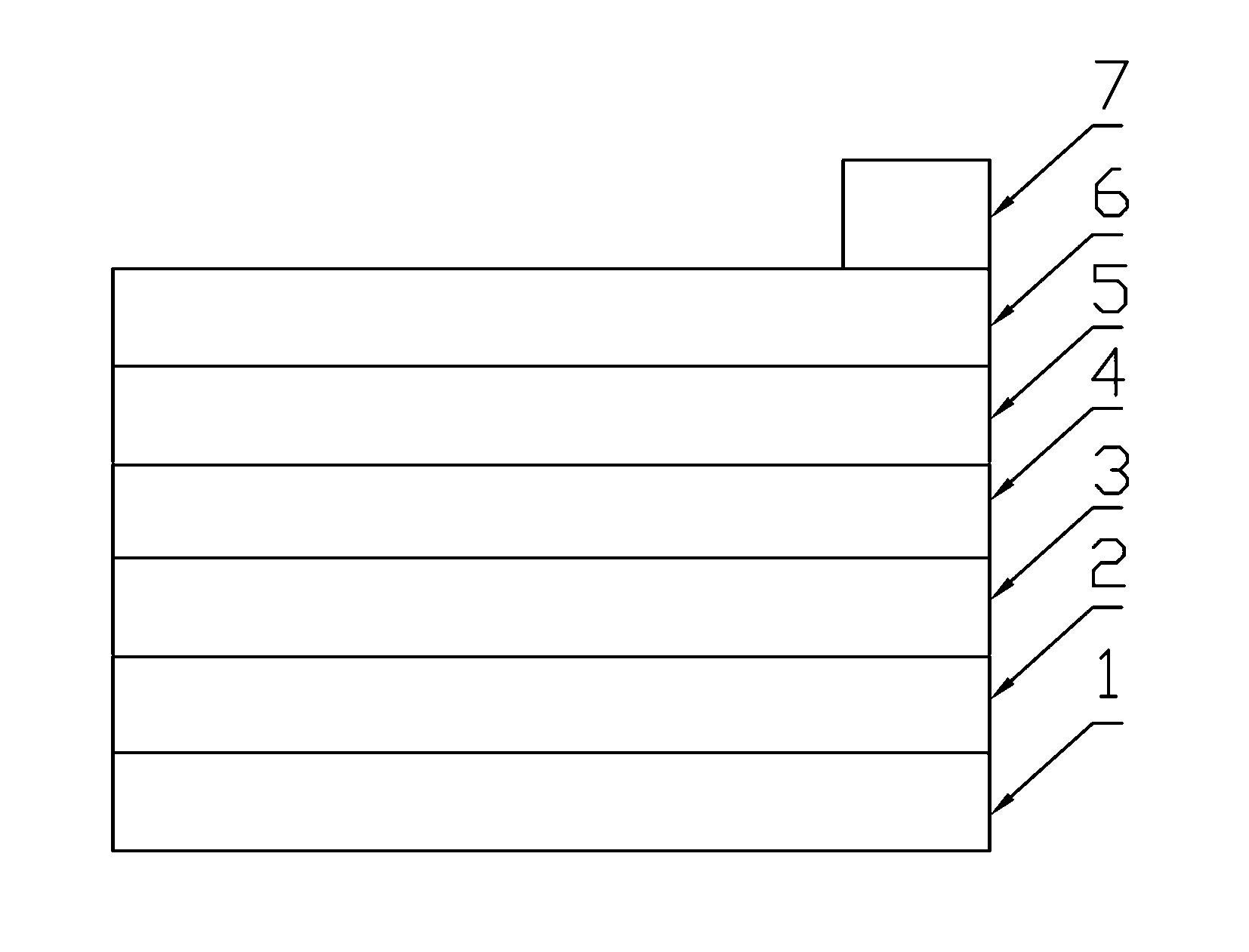

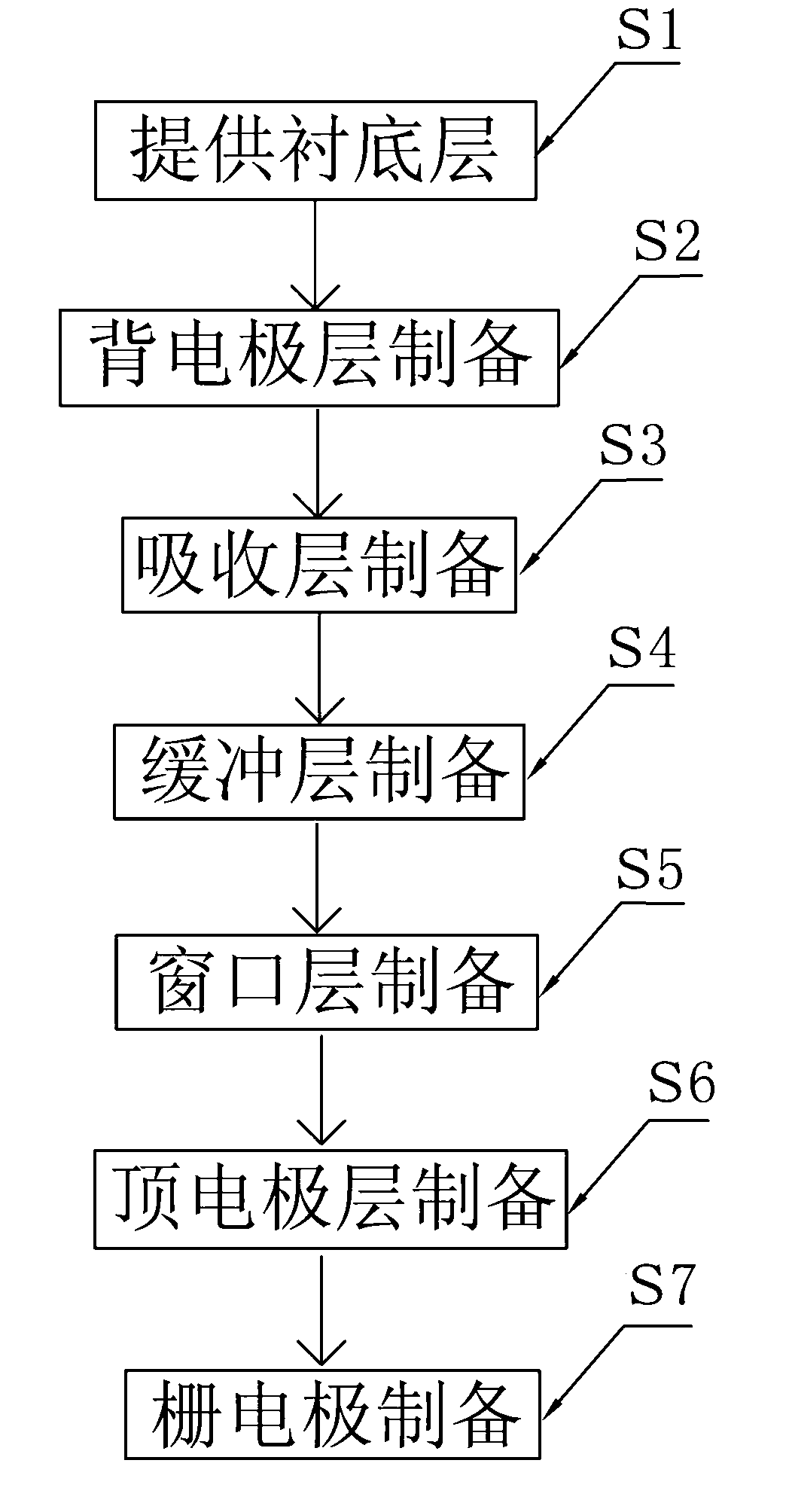

[0017] Such as figure 1 , figure 2 Shown, thin-film solar cell preparation method of the present invention is prepared by the following steps:

[0018] First, step S1 is performed to provide a substrate layer 1, and the substrate layer 1 is one of glass, stainless steel, silicon wafer, and polyimide.

[0019] Then carry out step S2, preparation of back electrode layer 2: adopt silver mirror reaction method to prepare silver thin film concrete steps are: add 1 milliliter concentration in clean container and be 2% silver nitrate solution, then add sodium hydroxide aqueous solution, then shake while Container, you can see the white precipitate, and then drop 2% dilute ammonia water drop by drop until the initial precipitate is just dissolved to get the silver ammonia solution; put the glass substrate into the container, and drop the glucose solution into the container , and warm the container in hot water after shaking. Soon, it can be seen that there is a bright mirror-like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com