Preparation method of high-conductivity aluminum-doped zinc oxide nano powder

An aluminum-doped zinc oxide, high-conductivity technology, applied in zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of powder agglomeration and uncontrollable appearance, and achieve controllable appearance, The effect of reducing production cost and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

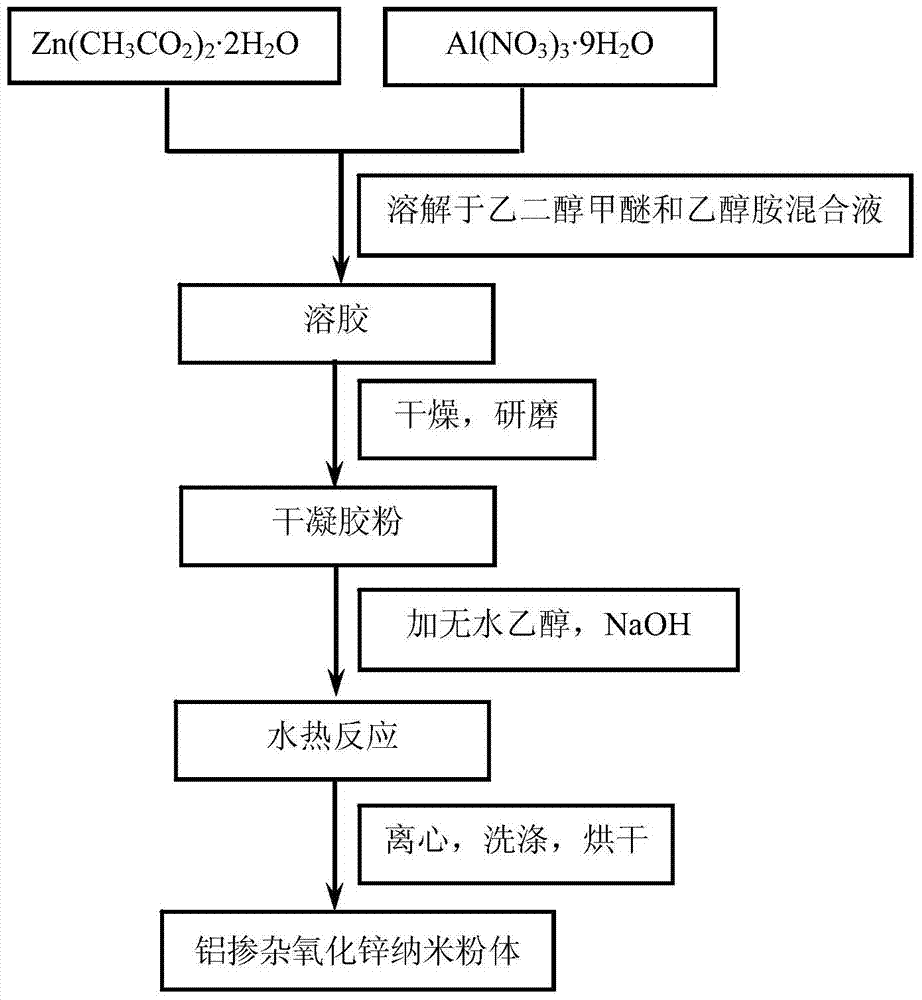

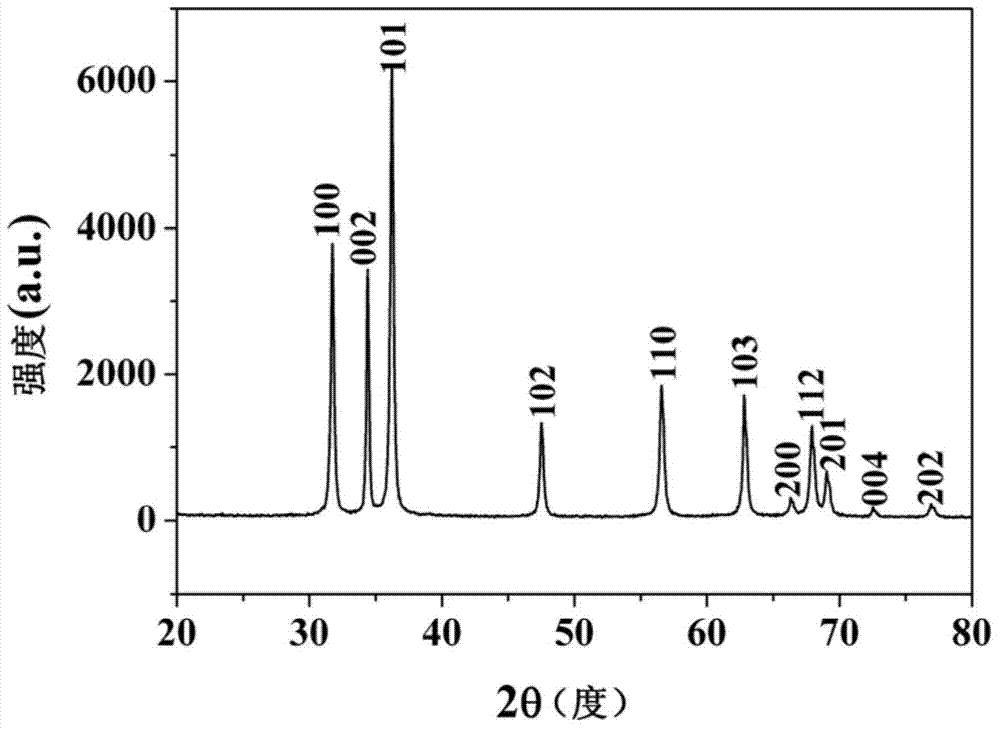

[0026] like figure 1 As shown, the preparation method of the AZO nanopowder with a doping amount of 2.0mol% in this embodiment comprises the following steps:

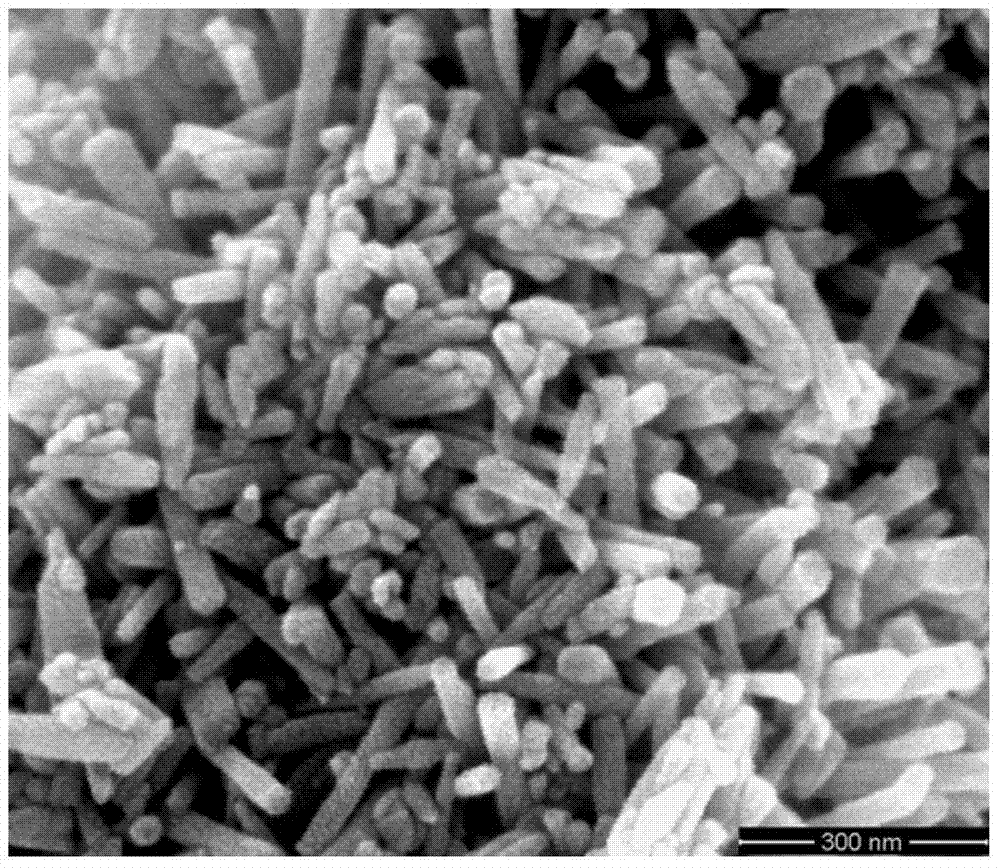

[0027] Weigh zinc acetate and aluminum nitrate and put them into a beaker, wherein the molar weight of aluminum ions accounts for 2% of the total molar weight of metal cations. Then add the mixed solution of ethylene glycol methyl ether and ethanolamine of 21ml, the volume ratio of ethylene glycol methyl ether and ethanolamine solution is 20, stir by magnetic force for 1 hour, be made into uniform sol, the molar concentration of metal cation in the sol is 0.75 mol / L. Put the generated sol in an oven, dry at 90°C to obtain a xerogel, and grind to obtain a xerogel powder, that is, a hydrothermal reaction precursor; put the prepared hydrothermal reaction precursor into a hydrothermal kettle, and Add absolute ethanol as a solvent and NaOH as a mineralizer to obtain a reaction solution, the concentration of NaOH in the rea...

Embodiment 2

[0035] The concentration of NaOH in the reaction solution of this example is 0.35 mol / L, and the rest of the conditions and steps are the same as in Example 1 to obtain a high-conductivity aluminum-doped zinc oxide nanopowder. Scanning electron microscope photos show that the nanopowder is spherical, and its volume resistivity is 8499Ω·cm.

Embodiment 3

[0037] The concentration of NaOH in the reaction solution of this example is 0.65 mol / L, and the rest of the conditions and steps are the same as in Example 1 to obtain a high-conductivity aluminum-doped zinc oxide nanopowder. Scanning electron microscope photos show that some rod-like crystals appear in the spherical nanoparticles, and its volume resistivity is 2304Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com