Method for preparing aluminum-doping zinc oxide nanometer sheet with photo-catalysis function

A nanosheet, photocatalytic technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of expensive equipment, complex preparation process, high energy consumption, and achieve good application prospects and significant photocatalytic degradation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

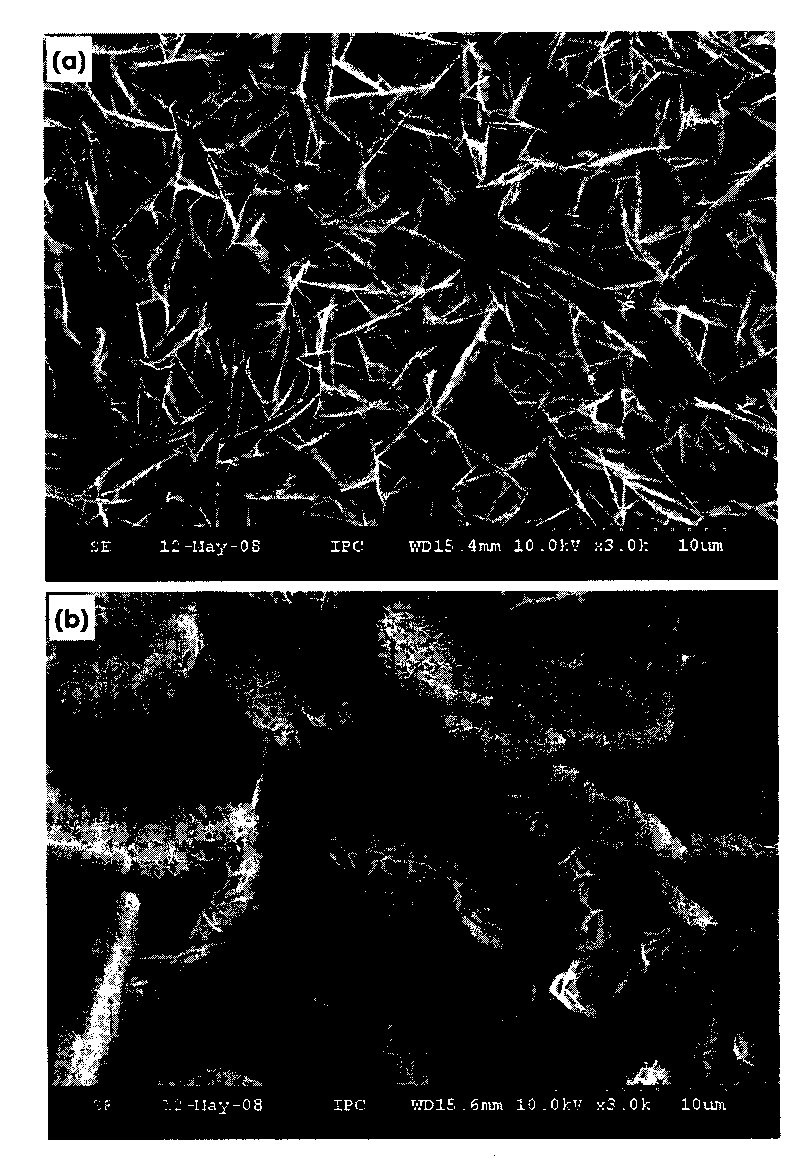

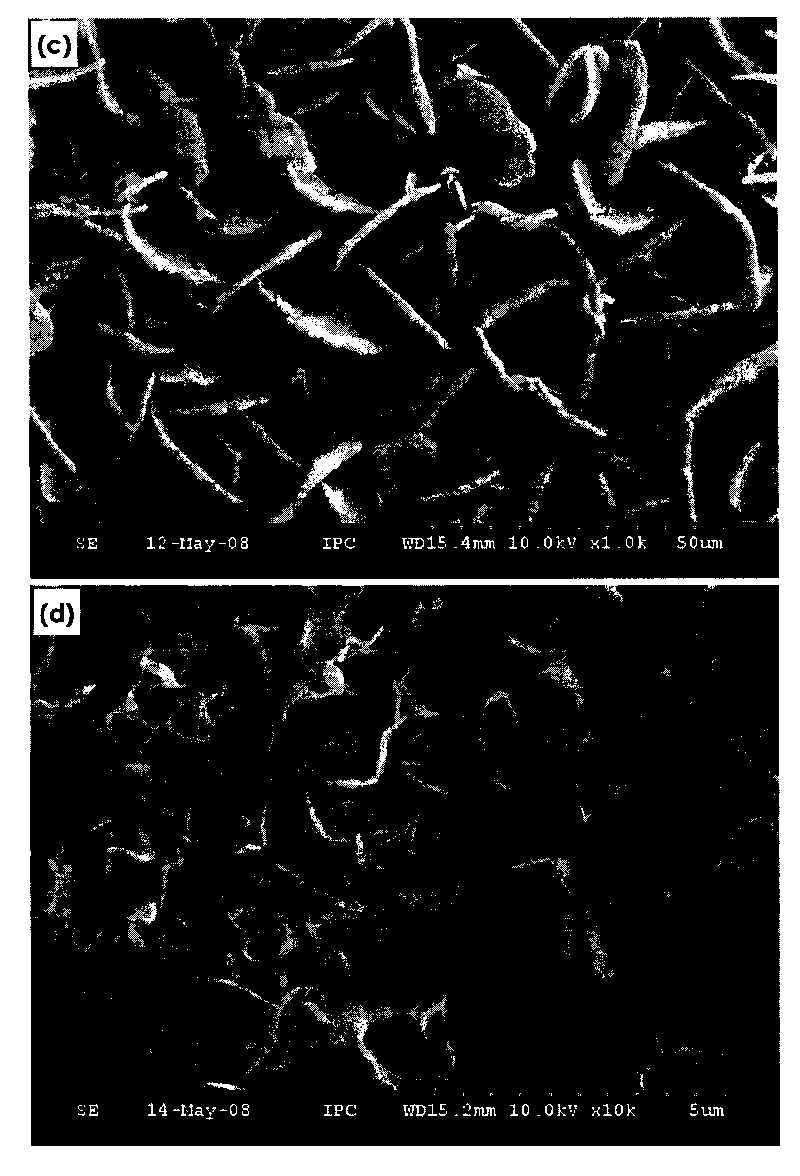

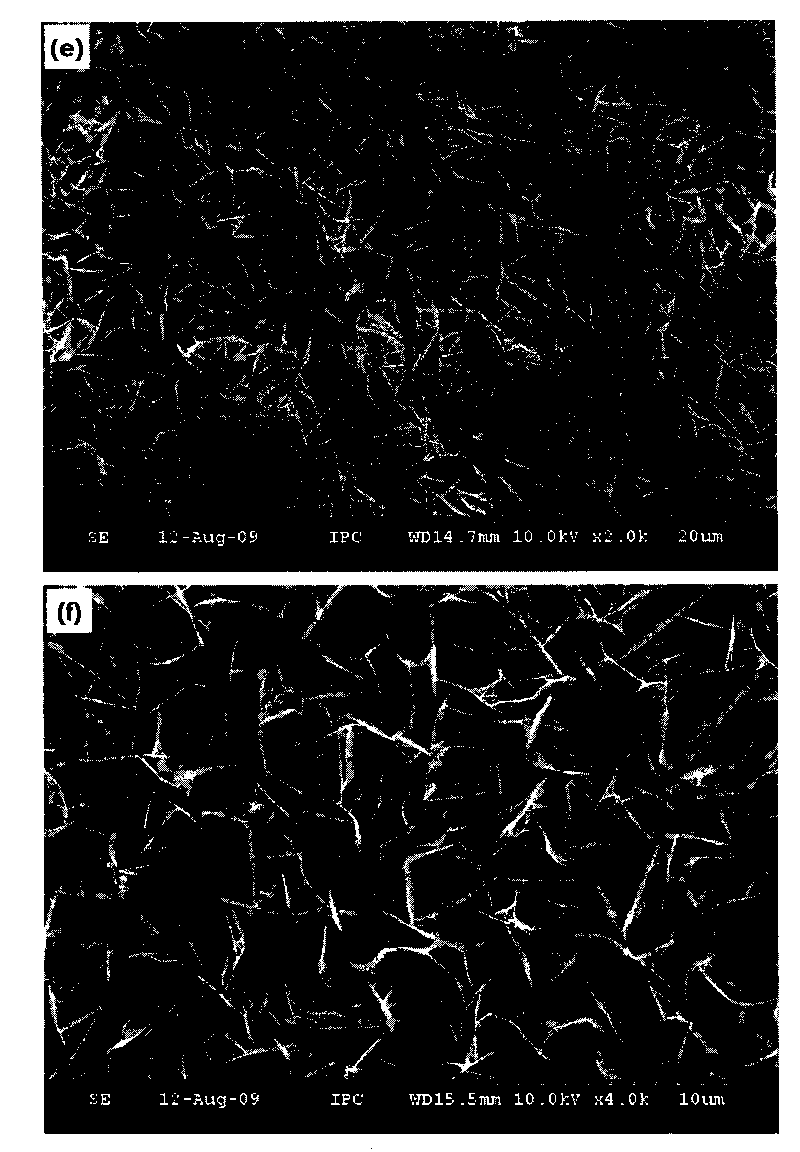

[0018] The ITO glass with a size of 1×3 cm was ultrasonically cleaned with acetone, ethanol and water for 5 minutes in sequence, and dried for later use. Formulated with Zn(NO 3 ) 2 The concentration is 5mM, Al(NO 3 ) 3 An aqueous solution with a concentration of 0.1 mM was used as the electrolyte. The electrolyte solution was poured into the electrolytic cell, with a Pt sheet as the counter electrode, a saturated calomel electrode (SCE) as the reference electrode, and a cleaned ITO glass as the working electrode. Use a water bath to control the temperature of the electrolyte in the electrolytic cell to 80°C, apply a potential of -1.2V to the working electrode relative to the reference electrode through an electrochemical analyzer, and react for 60 minutes to obtain a white film on the working electrode, which is The product Al doped ZnO nanosheets, the morphology is as follows figure 1 As shown in (a), the thickness of the nanosheet is about 20 nm, and the doping amount ...

Embodiment 2

[0020] The FTO glass with a size of 1×3 cm was ultrasonically cleaned with acetone, ethanol and water for 5 minutes in sequence, and then dried for later use. Formulated with Zn(NO 3 ) 2 The concentration is 100mM, AlCl 3 An aqueous solution with a concentration of 0.1 mM was used as the electrolyte. The electrolyte solution was poured into the electrolytic cell, with a Pt sheet as the counter electrode, a saturated calomel electrode (SCE) as the reference electrode, and a cleaned FTO glass as the working electrode. Use a water bath to control the temperature of the electrolyte in the electrolytic cell to 80°C, apply a potential of -1.2V to the working electrode relative to the reference electrode through an electrochemical analyzer, and react for 60 minutes to obtain a white film on the working electrode, which is The product Al doped ZnO nanosheets, the morphology is as follows figure 1 As shown in (b), the thickness of the nanosheet is about 10 nm, and the doping amount...

Embodiment 3

[0022] The ITO glass with a size of 1×3 cm was ultrasonically cleaned with acetone, ethanol and water for 5 minutes in sequence, and dried for later use. Formulated with Zn(NO 3 ) 2 The concentration is 50mM, Al(NO 3 ) 3 An aqueous solution with a concentration of 0.1 mM was used as the electrolyte. The electrolyte solution was poured into the electrolytic cell, with a Pt sheet as the counter electrode, a saturated calomel electrode (SCE) as the reference electrode, and a cleaned ITO glass as the working electrode. Use a water bath to control the temperature of the electrolyte in the electrolytic cell to 90°C, apply a potential of -1.6V to the working electrode relative to the reference electrode through an electrochemical analyzer, and react for 60 minutes to obtain a white film on the working electrode, which is The product Al doped ZnO nanosheets, the morphology is as follows figure 1 As shown in (c), the thickness of the nanosheet is about 500 nm, and the doping amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com