Waugh-type manganese molybdate included in dysprosium-isonicotinic acid, and preparation method and application thereof

A technology of manganese molybdate and isonicotinic acid is applied in the field of preparation of polyoxomolybdate chemical materials, which can solve problems such as photocatalytic performance that have not yet been seen, achieve good photocatalytic degradation, improve stability and improve reaction activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

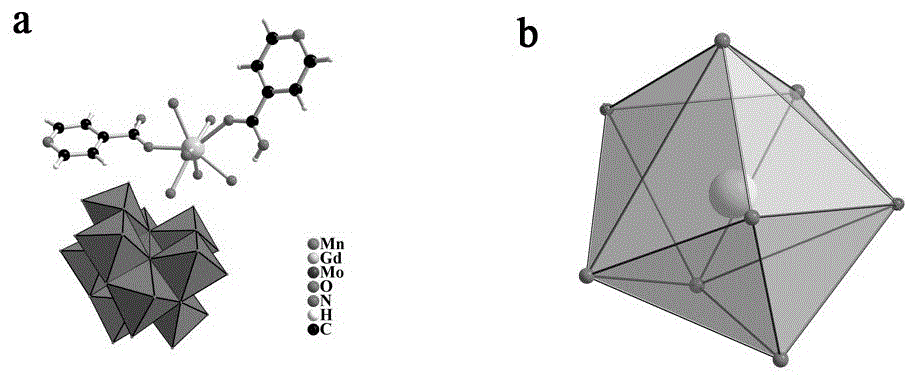

[0036] A Waugh-type manganese molybdate containing dysprosium-isonicotinic acid, its chemical formula is: (NH 4 ) 3 [Dy(Hina) 2 (H 2 O) 6 ][Mn IV Mo 9 o 32 ]·7H 2 O.

[0037] The Waugh-type manganese molybdate contained in the above-mentioned dysprosium-isonicotinic acid is synthesized by a traditional aqueous solution method, and its preparation method specifically includes the following steps:

[0038] 1) Prepare solution A: In a 25 mL beaker, dissolve ammonium heptamolybdate (2.002 g, 1.62 mmol) in distilled water with stirring and adjust its pH to 5.0 with glacial acetic acid, then add manganese acetate (0.120 g, 0.49mmol), isonicotinic acid (0.156 g, 1.27 mmol), dysprosium nitrate (0.120 g, 0.26 mmol) and 0.45 mL 30%H2 o 2 , stirred at room temperature for 20 minutes to form a homogeneous mixed phase, then placed in a water bath at 90±2°C and heated for 1 hour, took it out and filtered it into a 50 mL beaker while it was hot to obtain solution A;

[0039] 2) Pre...

Embodiment 2

[0042] A Waugh-type manganese molybdate containing dysprosium-isonicotinic acid, its chemical formula is: (NH 4 ) 3 [Dy(Hina) 2 (H 2 O) 6 ][Mn IV Mo 9 o 32 ]·7H 2 O.

[0043] The Waugh-type manganese molybdate contained in the above-mentioned dysprosium-isonicotinic acid is synthesized by a traditional aqueous solution method, and its preparation method specifically includes the following steps:

[0044] 1) Prepare solution A: In a 25 mL beaker, dissolve ammonium heptamolybdate (2.002 g, 1.62 mmol) in distilled water with stirring and adjust its pH to 5.0 with glacial acetic acid, then add manganese acetate (0.120 g, 0.49mmol), isonicotinic acid (0.156 g, 1.27 mmol), dysprosium nitrate (0.120 g, 0.26 mmol) and 0.45 mL 30%H 2 o 2 , stirred at room temperature for 20 minutes to form a homogeneous mixed phase, then placed in a water bath at 90±2°C and heated for 1 hour, took it out and filtered it into a 50 mL beaker while it was hot to obtain solution A;

[0045] 2) P...

Embodiment 3

[0048] A Waugh-type manganese molybdate containing dysprosium-isonicotinic acid, its chemical formula is: (NH 4 ) 3 [Dy(Hina) 2 (H 2 O) 6 ][Mn IV Mo 9 o 32 ]·7H 2 O.

[0049] The Waugh-type manganese molybdate contained in the above-mentioned dysprosium-isonicotinic acid is synthesized by a traditional aqueous solution method, and its preparation method specifically includes the following steps:

[0050] 1) Prepare solution A: In a 25 mL beaker, dissolve ammonium heptamolybdate (2.002 g, 1.62 mmol) in distilled water with stirring and adjust its pH to 5.0 with glacial acetic acid, then add manganese acetate (0.120 g, 0.49mmol), isonicotinic acid (0.156 g, 1.27 mmol), dysprosium nitrate (0.120 g, 0.26 mmol) and 0.45 mL 30%H 2 o 2 , stirred at room temperature for 20 minutes to form a homogeneous mixed phase, then placed in a water bath at 90±2°C and heated for 1 hour, took it out and filtered it into a 50 mL beaker while it was hot to obtain solution A;

[0051] 2) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com